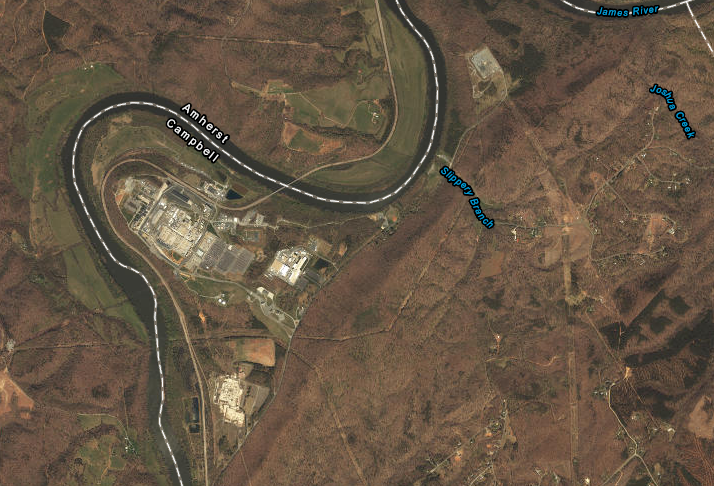

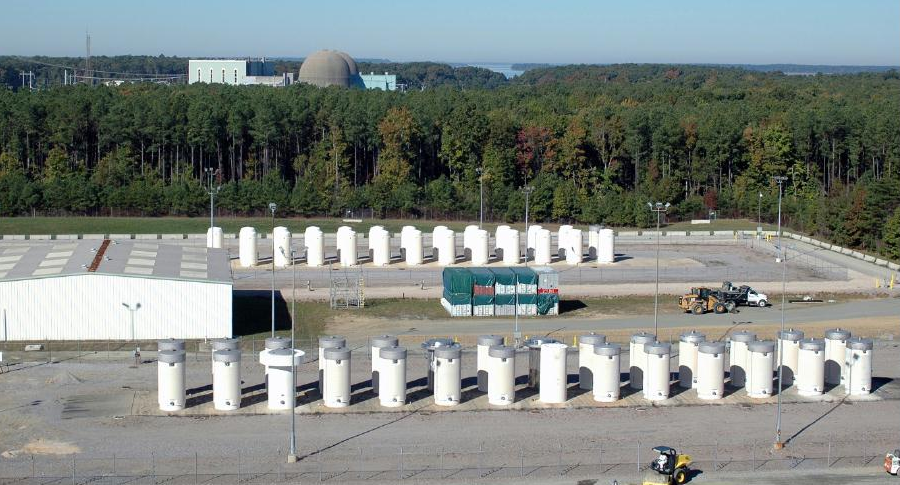

spent fuel assemblies are stored "temporarily" at the Surry Nuclear Power Plant, because the Federal government has not developed a permanent storage facility

Source: ESRI, ArcGIS Online

spent fuel assemblies are stored "temporarily" at the Surry Nuclear Power Plant, because the Federal government has not developed a permanent storage facility

Source: ESRI, ArcGIS Online

High-level radioactive waste is generated in Virginia by four nuclear pressurized water reactors at two sites in Virginia (Surry and Lake Anna), and at the BWXT facilities in Lynchburg. When nuclear-powered aircraft carriers are overhauled or scrapped at Newport News, spent fuel assemblies similar to those from commercial power plants are removed and shipped to Idaho by rail.

The BWXT facilities in Lynchburg examine reactors used by the US Navy, and "hot cell" research generates high-level Greater Than Class C (GTCC) radioactive waste. BWXT publicly reveals only that the waste is placed into stainless steel drums. Presumably the waste is mixed with low- or non-radioactive materiel ("downblended") before those drums are trucked or shipped by rail to the Waste Isolation Pilot Plant (WIPP) near Carlsbad, New Mexico. That site accepts low-level and Greater Than Class C (GTCC) radioactive waste from defense-related facilities.1

Most high-level radioactive waste in Virginia is associated with fuel assemblies used by Dominion Virginia Power to generate electricity at the Surry and Lake Anna nuclear power plants. The source of energy in those assemblies is uranium (U-235) fuel.

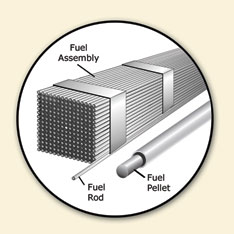

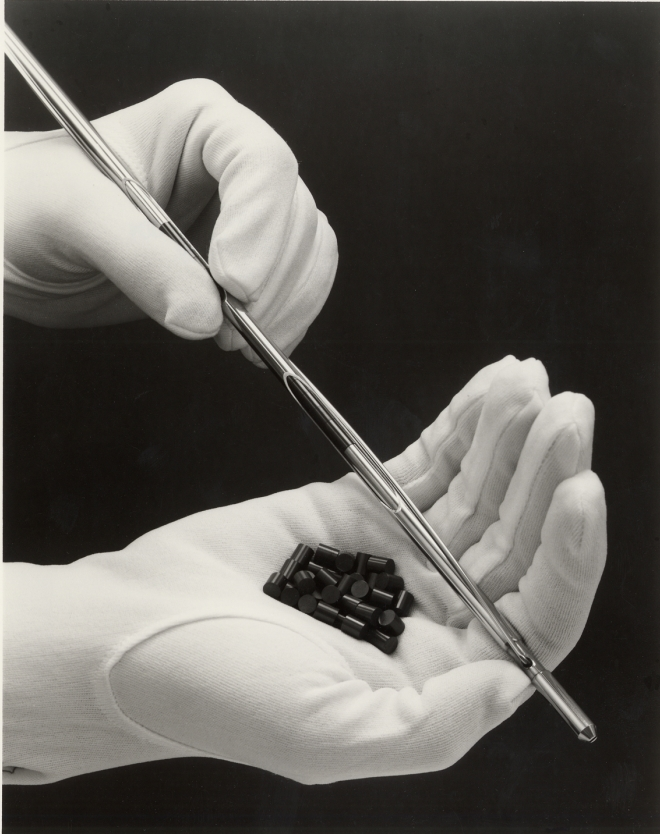

The uranium is compressed into ceramic pellets and inserted into metal-clad rods, and rods are aligned together to create fuel assemblies. Each of the nuclear reactors operated by Dominion Energy contains 157 fuel assemblies. A single fuel assembly consists of 204 fuel rods, loaded with 328 ceramic pellets of uranium dioxide. Each ceramic pellet has the energy equivalent to 1,800 pounds of coal, or 150 gallons of oil. Over 10 million pellets are used at each reactor to produce heat, producing pressurized steam that spins turbines to generate electricity.2

The uranium is compressed into ceramic pellets and inserted into metal-clad rods, and rods are aligned together to create fuel assemblies. Each of the nuclear reactors operated by Dominion Energy contains 157 fuel assemblies. A single fuel assembly consists of 204 fuel rods, loaded with 328 ceramic pellets of uranium dioxide. Each ceramic pellet has the energy equivalent to 1,800 pounds of coal, or 150 gallons of oil. Over 10 million pellets are used at each reactor to produce heat, producing pressurized steam that spins turbines to generate electricity.2

Inside reactors, fuel assemblies are positioned to initiate a critical nuclear reaction that generates heat, converting water into pressurized steam that spins a turbine and generates electricity. Before fuel assemblies are used in a reactor, they are only slightly radioactive from the U-235 isotope.

Dominion Virginia Power's nuclear power plants at Surry and Lake Anna import assemblies that are fabricated out-of-state. The BWXT facilities in Lynchburg make nuclear fuel assemblies for US Navy reactors. When initially created, nuclear fuel assemblies may be handled and transported without special shielding to block gamma rays. However:3

Surry Unit 1 started in December 1972, and Unit 2 started in May 1973. At North Anna, Unit 1 started commercial operation in June 1978 and Unit 2 in December 1980. By 2016, Dominion Virginia Power stored 2,760 metric tons of high-level radioactive waste at those two locations.4

In addition, high-level wastes from foreign reactors (originally supplied with nuclear fuel from the United States) have been shipped through Portsmouth, Virginia to Federal storage facilities at the Savannah River Plant in Aiken, South Carolina and on to the Idaho National Engineering and Environmental Laboratory in Idaho Falls, Idaho. Ships arrived on average once a week with 15-ton casks of lead and steel. Annually, about 10,000 pounds of high-level radioactive waste from foreign sources was shipped through Portsmouth. It all went to South Carolina for reprocessing; none remained in Virginia.

In 1986, spent fuel rods from Taiwan were shipped to Portsmouth after a lawsuit blocked plans to unload them in California. A Sierra Club lawsuit blocked such shipments through Virginia in 1988. Since then, shipments have been redirected to the Charleston Naval Weapons Station in South Carolina. After the collapse of the Soviet Union, nuclear materials recovered from former Soviet military and research facilities were collected and shipped to reprocessing sites in South Carolina and Idaho. Those shipments came into the United States via the Charleston Naval Weapons Station, not through Portsmouth.5

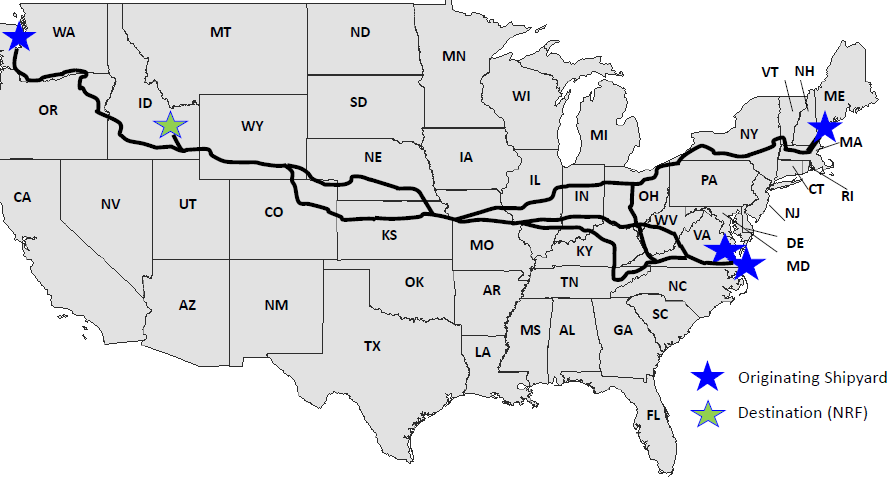

Nuclear reactors with highly-enriched uranium provide power for new aircraft carriers and submarines built at Newport News. Fuel assemblies with "fresh" nuclear material are installed in the reactors when a ship is built. Later, when aircraft carriers go through Refueling and Complex Overhauls, spent fuel assemblies are removed and fresh ones (with more U-235) are installed. Modern nuclear-powered submarines do not require refueling during their 33-year life, but aircraft carriers require one refueling in their 50-year life.

Removal of spent fuel assemblies involves bringing empty casks onto the ship, transferring the old fuel into the casks, them moving the casks off the ship and to a disposal site. The used fuel assemblies, with highly-radioactive activated metal now emitting gamma rays, are sent to the Naval Reactors Facility at the Department of Energy's Idaho National Laboratory. Used assemblies are examined there, then stored at the Expended Core Facility/Dry Storage Facility managed by the Department of Energy.

Between 1953 and 1992, used fuel was reprocessed in Idaho to extract U-235 which could be used in new fuel assemblies. Since 1996, the used fuel assemblies have been placed into dry storage casks rather than pools of water.6

used fuel assemblies from aircraft carriers are radioactive waste (unlike fresh assemblies) and transported by rail from Newport News to Idaho in M-290 shipping containers

Data Source: US Nuclear Waste Technical Review Board, Naval Spent Fuel Transportation

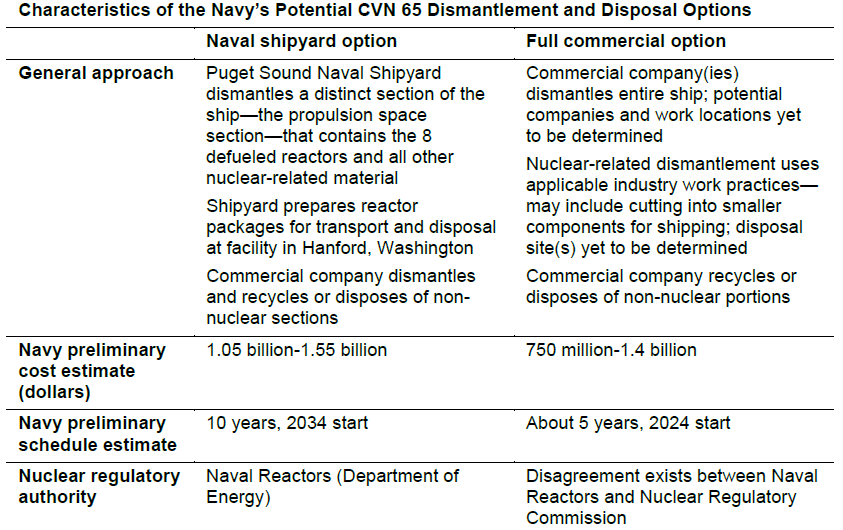

The USS Enterprise (CVN-65) was "defueled" starting in 2013 after six years of planning. That process was completed in 2018, with the fuel rod assemblies shipped to the Department of Energy's Idaho National Laboratory.

The ship, which was the first nuclear-powered carrier built for the US Navy and the first to be decommissioned, had eight reactors. The later Nimitz and Ford class carriers were designed with just two reactors. A longer shipping container, the M-290 cask, was developed. It eliminated the need to disassemble the used nuclear fuel assemblies from those eight reactors and then move the radioactive waste into standard containers used for commercial power plants.

the longer M-290 cask was developed to transport used nuclear fuel assemblies from the USS Enterprise aircraft carrier to Idaho

Source: US Nuclear Waste Technical Review Board, Naval Spent Fuel Transportation

After defueling, the US Navy had planned to tow the defueled USS Enterprise around the tip of South America to the Puget Sound Naval Shipyard. Workers there were supposed to cut out the eight reactor compartments, the portion of the ship where the nuclear fuel had been located. The reactor compartments would be encased in steel, then hauled to Hanford for final burial. Reactors from nuclear-powered subs and cruisers have been buried there previously.

When costs ballooned to over $1 billion and it became clear that the Puget Sound Naval Shipyard and Intermediate Maintenance Facility did not have sufficient capacity to handle the USS Enterprise, the Navy considered contracting with commercial companies to scrap the warship. Only a small part of the massive job involves dealing with radioactive material.

The hulk would be broken apart at Newport News or transported to another private shipyard. If the reactor compartments were disassembled at Newport News rather than at the Puget Sound Naval Shipyard, the radioactive metal components might be disposed of as low-level radioactive waste. If needed, pieces with excessive remaining radioactivity could be shipped by train across Virginia to Idaho or Washington for disposal.

in 2013, the USS Enterprise was towed from Naval Station Norfolk to the Newport News Shipbuilding facility for defueling

Source: Huntington Ingalls Industries, Newsroom: Aircraft Carrier Inactivation

The proposal to use a civilian shipyard created a bureaucratic challenge. The US Navy argued that the oversight of scrapping a nuclear warship at a private shipyard was the responsibility of the Nuclear Regulatory Commission, which dealt with civilian activities involving nuclear material. The Nuclear Regulatory Commission argued the Naval Reactors office of the US Navy had responsibility for scrapping the USS Enterprise, noting that the Navy had already handled 130 reactors taken from nuclear-powered submarines and cruisers.7

Virginia is an "Agreement State" with the Nuclear Regulatory Commission. The civilians in the Virginia Department of Health's Radiological Health Program would have to regulate how the highly-classified nuclear reactor components would be disassembled safely.8

The inactivation of the USS Enterprise at the Newport News Shipbuilding facility was completed in 2018. The hulk was still stored there when the US Navy issued the Environmental Impact Statement on dismantlement in 2023, choosing to have a commercial shipyard perform the task. The US Navy planned for the commercial shipyard to cut up the eight reactor compartments and transport the low level radioactive waste in 440 container express (CONEX) boxes to one or more licensed commercial disposal sites in Texas, Utah, and South Carolina.9

in 2018, the Government Accountability Office summarized the costs and time required for decommissioning the USS Enterprise

Source: Government Accountability Office, Aircraft Carrier Dismantlement and Disposal (GAO-18-523)

To date, only spent fuel assemblies have been removed from military vessels at Newport News. When US Navy has scrapped other nuclear-powered ships, the still-radioactive reactors (the metal in which the fuel assemblies were placed) were removed at the Puget Sound Naval Shipyard and Intermediate Maintenance Facility in Bremerton, Washington. The reactors have been placed in disposal trenches at Hanford, Washington. The fuel assemblies have been sent to the Idaho National Engineering and Environmental Laboratory in Idaho Falls, Idaho.

high-level nuclear waste from the USS Enterprise went by train to Idaho, and reactor components could go to Hanford in Washington

Source: US Nuclear Waste Technical Review Board, Naval Spent Fuel Transportation

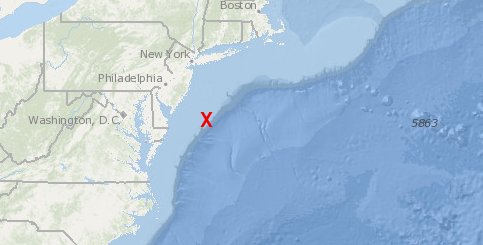

The US Navy once relied upon ocean disposal. When the reactor of the USS Seawolf was replaced in 1959, the old reactor was dumped in the Atlantic Ocean off the coast of Delaware. The USS Seawolf was the only US submarine built with a reactor cooled by liquid sodium rather than by pressurized water. That unique reactor is the only high-level nuclear waste that was officially dumped near the Virginia coast before the 1972 London Dumping Convention banned such disposal.10

the old reactor from one US submarine, the USS Seawolf, was dumped in the ocean off Delaware in 1959

Source: ESRI, ArcGIS Online

Most of the high-level radioactive waste in Virginia comes from civilian facilities, not US Navy warships. All high-level radioactive waste generated in Virginia by civilian nuclear power plants is stored "temporarily" in Virginia.

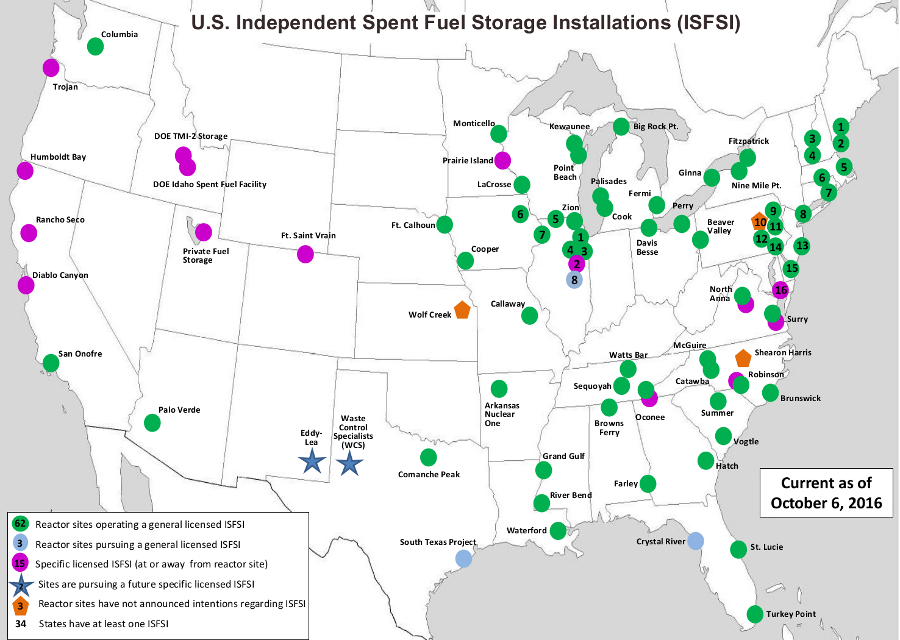

The nuclear plants at North Anna and Surry are licensed by the Nuclear Regulatory Commission as Independent Spent Fuel Storage Installations (ISFSI's), but these were intended to be short-term storage locations.

Virginia has two of the independent spent fuel storage installations authorized by the Federal government

Source: US Nuclear Regulatory Commission, Dry Cask Storage

The waste will be dangerously radioactive for thousands of years, while the nuclear power plants will be decommissioned in decades. The Federal government has plans to transfer all spent fuel assemblies to a single national repository, but efforts to build such a repository have been blocked. When North Anna and Surry are finally decommissioned, casks filled with their high-level nuclear waste may still be located on each site.

Babcock & Wilcox (now BWX Technologies) has fabricated research reactor fuel elements for colleges, universities and national laboratories just east of Lynchburg since 1958

Source: ESRI, ArcGIS Online

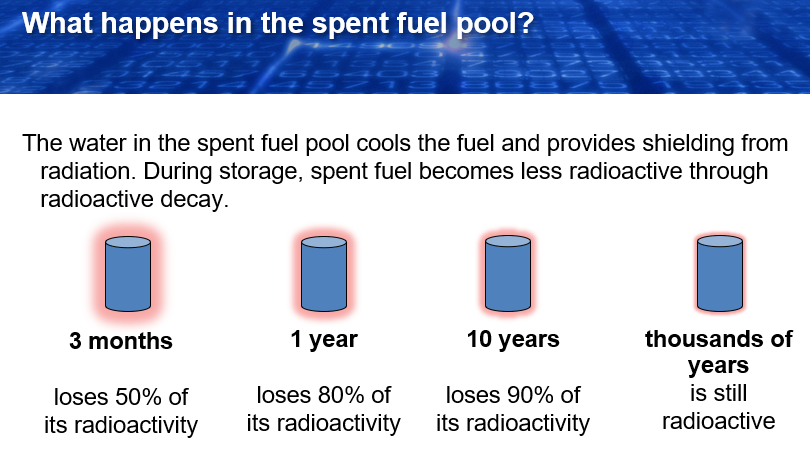

When the uranium in a fuel assembly has decayed so much that nuclear fission is no longer creating sufficient heat after 12-24 months, the utility company refuels the reactor with new fuel assemblies.

Typically one-third of the assemblies are removed during each refueling operation, and each refueling creates a new supply of radioactive waste that requires special handling for disposal. Occasionally, the fuel rods break and ceramic pellets are released into the cooling system of the reactor. Pellets are pulverized by the filtration system (water at North Anna flows at 300,000 gallons a minute), or retrieved when fuel assemblies are removed and the breakage discovered.11

over 300 ceramic pellets of uranium dioxide are placed inside a metal rod, and over 200 rods are aligned to create a single fuel assembly

Source: Department of Energy, Yucca Mountain

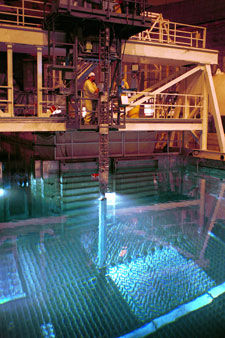

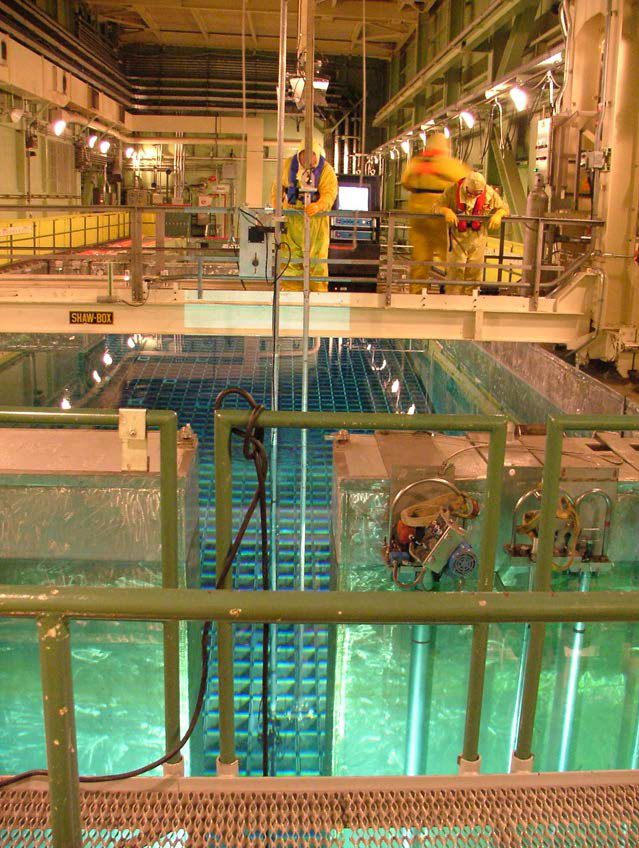

The assemblies are no longer economical for use in the reactors. The radioactive elements in the ceramic pellets, including plutonium and uranium, still generate heat. Those elements, plus the irradiated assemblies with neptunium, americium and other "actinides," emit dangerous radiation. After removal from the reactor, the spent fuel assemblies are placed in deep pools of water for 3-10 years to keep the radioactive waste from melting. The water in the pool plus special neutron absorber pads placed between assemblies also block hazardous radiation.

radioactive waste from a nuclear power plant is stored initially in a pool of water

Source: Office of Civilian Radioactive Waste Management, Science, Society, and America's Nuclear Waste, Radiation Exposures: Sources, Doses, and Protection

The water-filled pools were designed originally to accommodate temporary storage of nuclear waste at North Anna and Surry, before the spent fuel assemblies were reprocessed or transferred to a permanent storage repository.

storing spent fuel assemblies in a wet pool allows heat to dissipate, and blocks gamma rays

Source: Department of Energy, Waste from

Nuclear Power Plants

Reprocessing spent fuel rods from nuclear power plants is technically feasible. Isolating plutonium from the rods would allow recycling of the remaining U-235. However, President Carter banned reprocessing in the United States, responding to fears that plutonium could be diverted from reprocessing plants in other countries to produce unsanctioned nuclear weapons.

The US Congress established in the Nuclear Waste Policy Act in 1982 that the Federal government would create a permanent waste repository, and would store all high-level nuclear waste once it was removed from nuclear power plants. The government started collecting fees from utilities in 1983 to fund development of the repository, and committed to accept high level radioactive waste for permanent disposal deep underground.

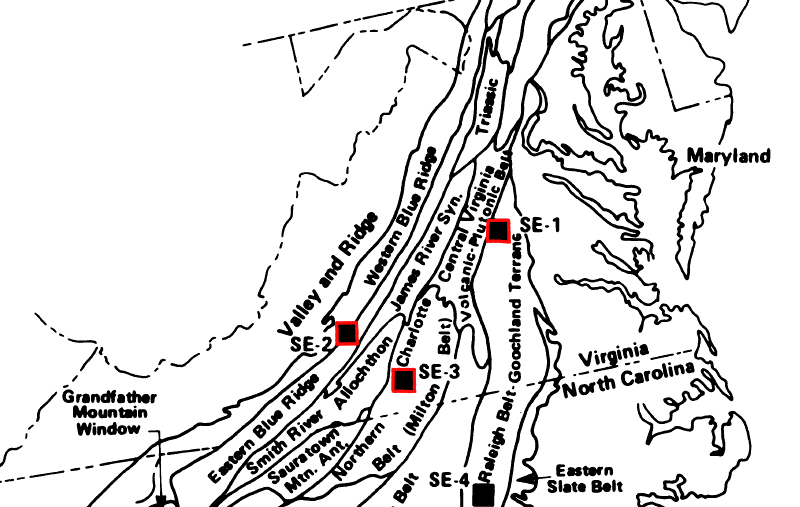

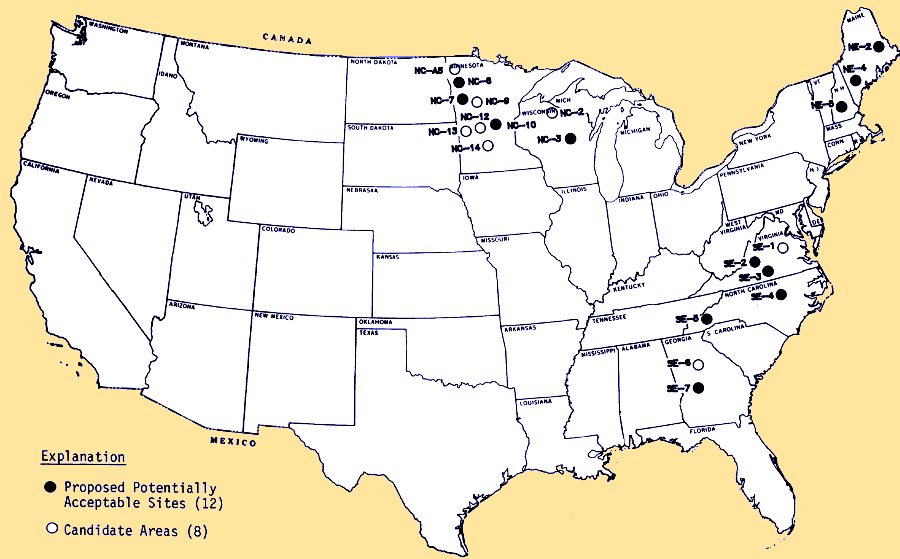

The Department of Energy initially proposed developing one facility for disposal of high-level radioactive wastes in the western US (to open in 1998) and one in the eastern states (to open in 2006). For an east-of-the-Mississippi River site, the Department of Energy examined 235 crystalline rock bodies where rocks were exposed or near the surface in 17 states.

The geology had to be suitable for long-term (10,000 year) isolation of radioactive spent fuel assemblies from commercial power reactors and high-level waste from defense-related facilities. The repository could be located 1,150-2,620 feet below ground. Storage was expected to occupy 2,200 acres below the surface, but the surface operations would require only 400 acres.

Ten disqualifying factors were used to define suitable sites. For example, places with quarries or boreholes were inappropriate because pre-existing mining/drilling activities increased the risk that radioactivity could leak out to the surface or groundwater aquifers. Proximity to places with population densities of 1,000 or more persons per square mile, and proximity to designated critical habitat for threatened and endangered species, were some of the other screening criteria.

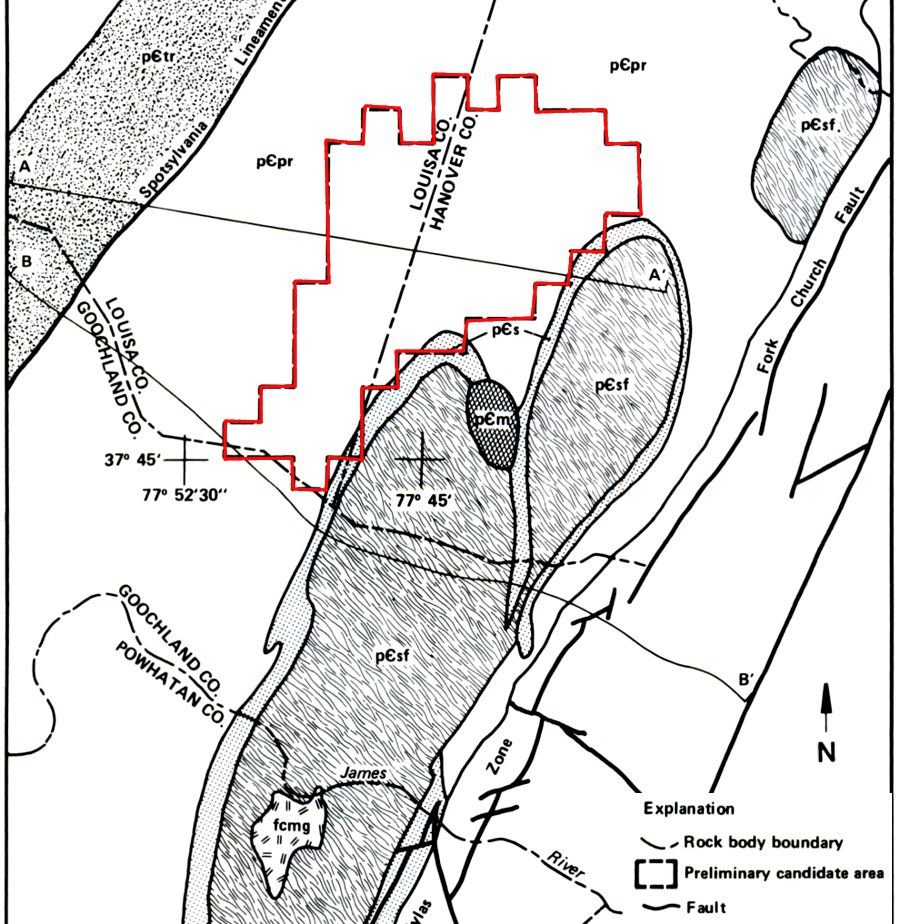

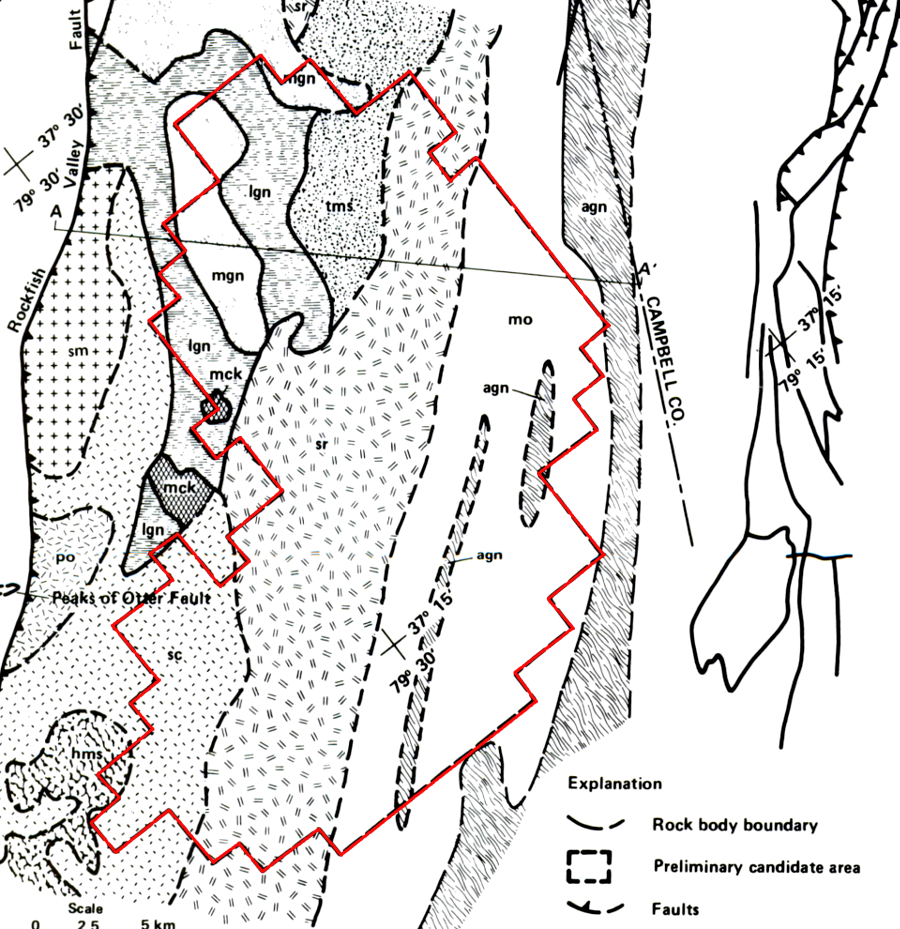

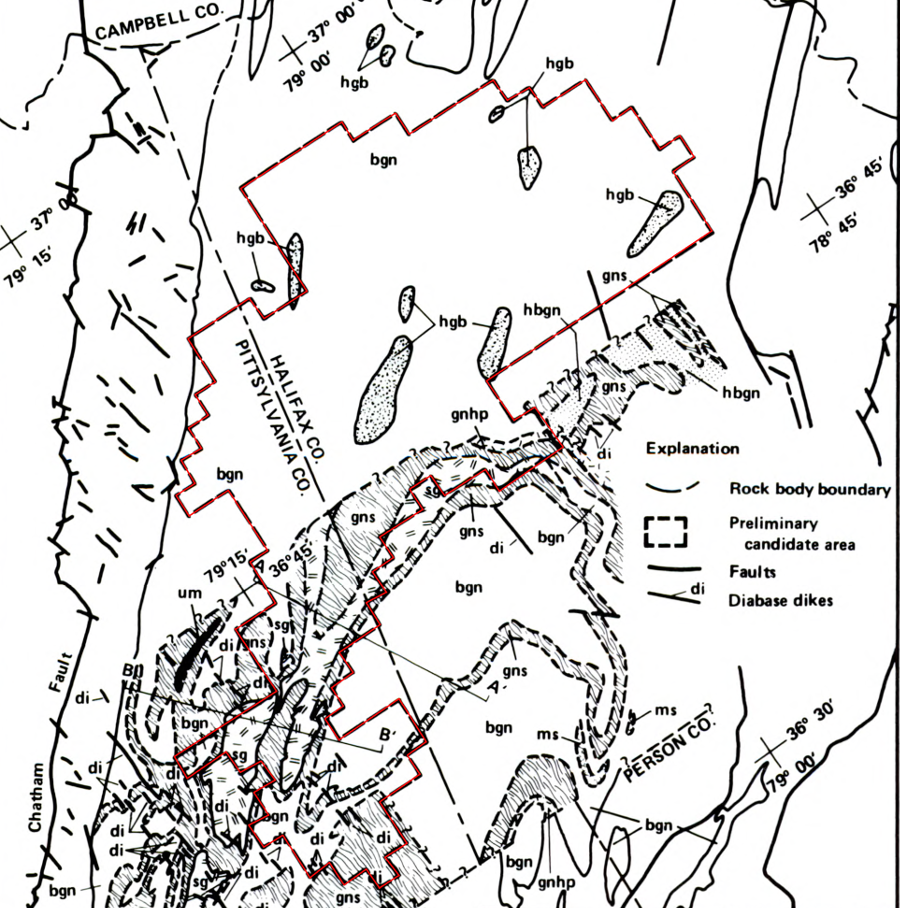

The choices narrowed in the 1980's to 12 "Proposed Potentially Acceptable Sites" and 8 "Candidate Areas" in Virginia, Georgia, Maine, Minnesota, Wisconsin, North Carolina and New Hampshire. The Department of Energy considered three locations in Virginia: a 64-square mile Candidate Area in Goochland, Louisa, and Hanover counties (SE-1), plus two Proposed Potentially Acceptable Sites. One was a 209-square mile tract in Bedford County (SE-2), and the other was a 307-square mile tract on the border straddling Halifax/Pittsylvania counties (SE-3).

The SE-1 site near Fredericksburg was less desirable due to higher population densities nearby, so it was labeled as just a "candidate area." The other two Virginia locations were designated as "Proposed Potentially Acceptable Sites."12

in 1986, the Department of Energy identified three locations in Virginia that were suitable for a geologic repository to store high-level radioactive waste underground for at least 10,000 years

Source: Department of Energy, Area Recommendation Report for the Crystalline Repository Project (Figure 3-117)

preliminary candidate area SE-1 in Goochland, Louisa, and Hanover counties was located in the Fredericksburg Complex and State Farm gneiss

Source: Department of Energy, Area Recommendation Report for the Crystalline Repository Project (Figure 3-120a)

The report assessed the risk of earthquakes in the potential locations. For the SE-1 site 11 miles from the North Anna Nuclear Power Plant, the Department of Energy concluded:13

In 2011, a 5.8 magnitude earthquake with its epicenter in Louisa County revealed the undetected presence of the Quail fault. Movement on that fault increased the risk that fluids could migrate within the granitic complex, and even escape to the surface.

preliminary candidate area SE-2 in Bedford County stretched for 22 miles long and 13 miles wide on top of the Lovingston massif

Source: Department of Energy, Area Recommendation Report for the Crystalline Repository Project (Figure 3-127b)

Public reaction was negative. Senator Paul Trible of Virginia was one of many Virginia officials who opposed any permanent nuclear waste storage facility in Virginia. At a Department of Energy hearing in Ashland, he highlighted why a site in Goochland, Hanover and Louisa counties would not be suitable:14

preliminary candidate area SE-3 in Halifax/Pittsylvania counties was located in the Virgilina Gneiss

Source: Department of Energy, Area Recommendation Report for the Crystalline Repository Project (Figure 3-134a)

In 1986, the Reagan Administration dropped efforts to locate a repository anywhere east of the Mississippi River. It focused on just one western site, choosing between Yucca Mountain in Nevada, Deaf Smith County in Texas, and Hanford in Washington state. All three areas had low population densities, as well as suitable geological characteristics.

The primary justification for choosing just one site was political. Elected officials from all other potential locations would be able to tell their constituents that the radioactive material would be located outside their electoral district.

Plutonium-239 has a half-life of 24,000 years, so whatever location was selected for a high-level waste repository would not have any other potential uses. There was an economy of scale to consider; simplifying analysis of the security, environmental, and other risks could justify centralization of high-level nuclear waste. However, whatever site was chosen for a repository to store spent fuel assemblies would become a permanent "national sacrifice area," dedicated to maintaining nuclear waste in a safe condition before radioactivity naturally declines to safe levels and not suitable for human habitation, farming, or any commercial uses.

In 1987, Yucca Mountain in Nye County, Nevada was selected after scientific assessments suggested it was suitable geologically. Congress over-rode the objections from Nevada and amended the 1982 Nuclear Waste Policy Act, choosing one site in a political decision that became known as the "Screw Nevada" bill. A Virginia Environmental Law Journal article described a lawsuit over the decision using the colorful title "Nevada v. Watkins: Who Gets the Shaft?"

The Speaker of the House was Jim Wright Jr. from Texas, and the House Majority Leader was Tom Foley from Washington. At the time, no one from Nevada held a position in Congress with strong political clout, so Deaf Smith County and Hanford were eliminated from consideration and Yucca Mountain was selected.15

Yucca Mountain was attractive geologically because it was so dry, limiting the risk of water spreading the nuclear waste

Source: Berkeley Lab, Getting the Neptunium out of Nuclear Waste

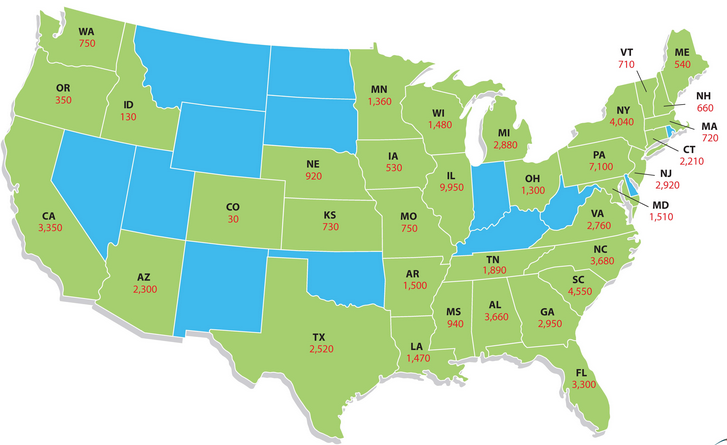

Just one location was required in part because the volume of highly-radioactive waste produced by nuclear power plants is small. The Government Accountability Office (GAO) stated in 2011 that the 65,000 metric tons of commercial spent nuclear fuel was "enough to fill a football field nearly 15 feet deep." By 2014, the total had risen to 72,000 metric tons, and it was stored at 75 sites in 33 states. Even if current volume doubled by 2055 as projected by GAO, the total would be still be roughly 150,000 cubic yards - small enough to fit in a single Northern Virginia basalt quarry.16

The Nevada repository was supposed to start accepting high-level radioactive waste in 1998. The Department of Energy began construction of a 5-mile tunnel underneath Yucca Mountain. It drilled cores, identified geological faults, and evaluated the long-term flow of water. The Environmental Protection Agency (EPA) sought to develop standards for acceptable levels of offsite releases of radioactive material from repositories.

There were no precedents for storing nuclear waste over tens of thousands of years, requiring unprecedented and hard-to-document predictions of risk in the environmental analyses. There were inadequate differences between science and speculation when seeking answers to some questions, such as the potential for future changes in the climate to bring rainfall to Yucca Mountain and corrode storage casks. The Department of Energy prepared material for obtaining an operating license from the Nuclear Regulatory Commission, consistent with Environmental Protection Agency standards, but the Federal agencies failed to meet the 1998 deadline.

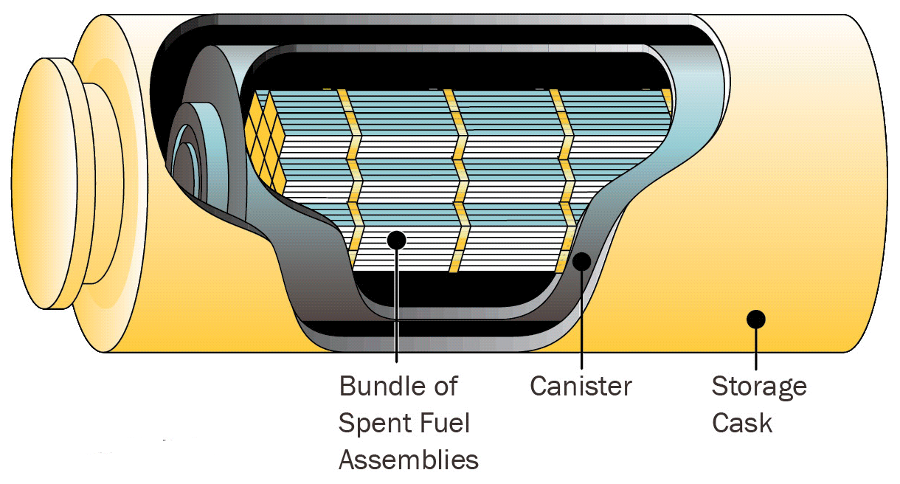

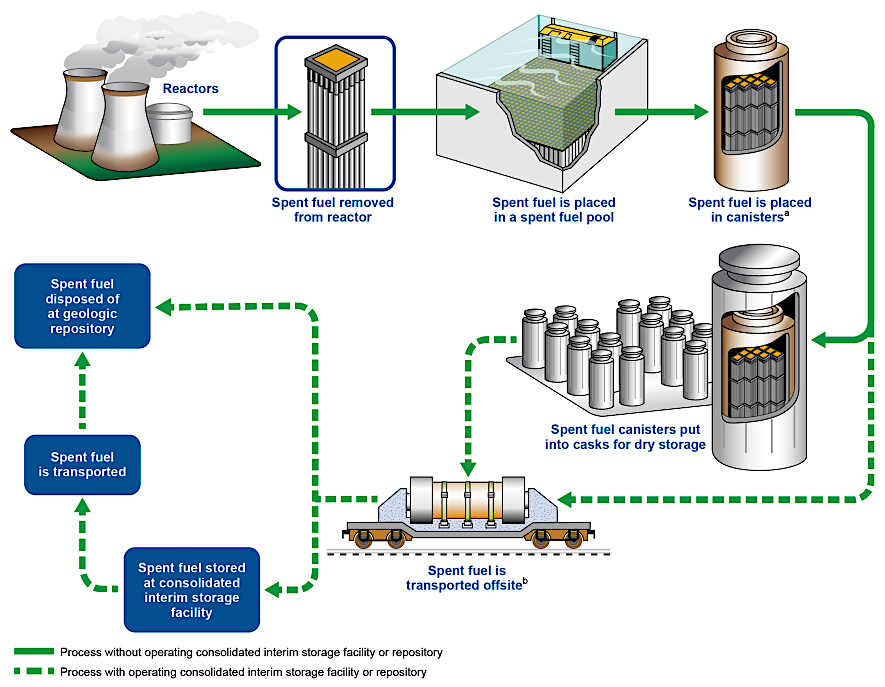

When it became clear that reprocessing nuclear waste would not be authorized and then the Federal permanent repository would not be completed as anticipated, Dominion Virginia Power adopted a long-term approach for storing the waste on site at Surry and North Anna that was more cost-effective than building more and more pools.

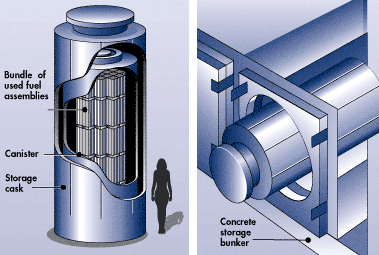

In the "dry cask" storage solution, used fuel assemblies are moved from the wet pool into steel casks surrounded with a thick outer coating of concrete. Each cask weighs 115 tons, and is expected to remain intact for as long as the radioactive waste is hazardous.

North Anna pool and fuel handling equipment

Source: US Nuclear Waste Technical Review Board, High Burnup Spent Fuel Data Project

To move the spent fuel assemblies from the wet pool into dry casks, the casks are first placed inside the pool. The fuel rods are loaded into the casks, the lid of the cask is sealed, water is pumped out, and finally helium is pumped into the cask. Lids of the cask can be bolted or welded.

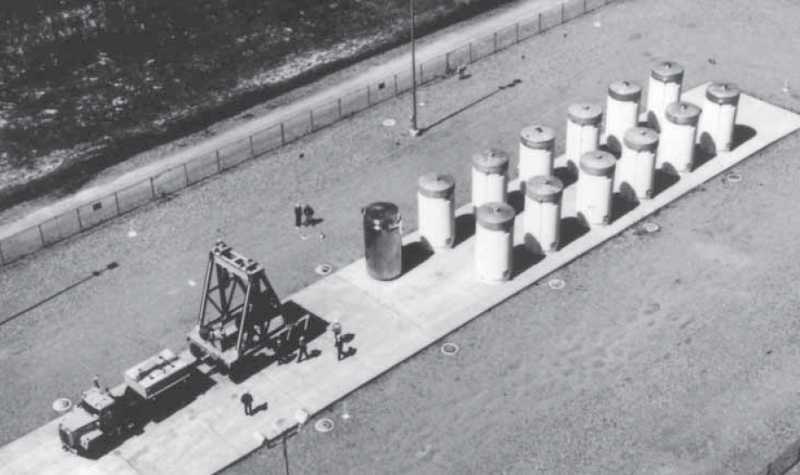

Rows of casks filled with radioactive waste sit on concrete pads. Storage in the casks requires far less maintenance than storage in the pools, reducing cost of short-term storage while awaiting completion of the permanent repository. The pads are not proposed to be permanent storage locations, but the marginal cost of maintaining them is low.

to make room for recently-removed fuel assemblies in the pool, older assemblies are transferred to dry casks in which they will be stored permanently

Source: US Nuclear Regulatory Commission, Spent Fuel Pools

Removal of spent fuel assemblies from the water-filled pools reduced both costs and the risks of an accidental release of radiation. If a pool were to drain completely, the spaces between the stored assemblies would still prevent a nuclear reaction from starting, but the zirconium cladding in the assemblies could oxidize and ignite. A zirconium cladding fire could spread radioactive particles downwind, if the backup systems to restore water failed. Moving assemblies to dry casks eliminates the risk of fire.17

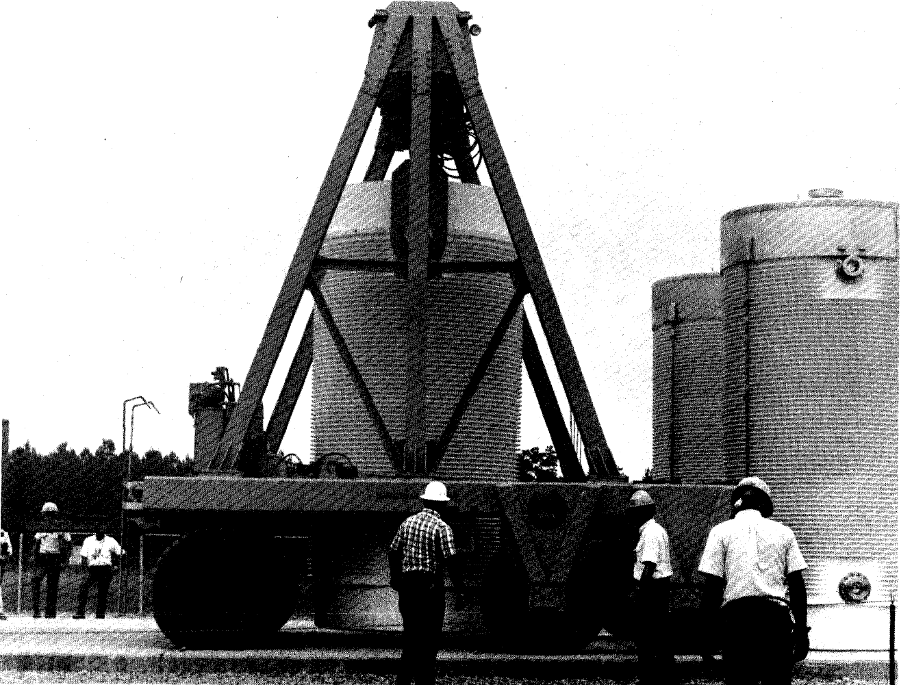

Dominion Virginia Power obtained the first Federal approval to use dry storage technology and opened the first dry cask storage facility in the United States at Surry, followed by one at North Anna.18

placing the third cask at Surry on the concrete pad

Source: Department of Energy Office of Civilian Radioactive Waste Management, Annual Report to Congress - August, 1988 (Figure 7-1)

Thanks in part to its long experience, the utility later partnered with the Department of Energy to assess the suitability of cask storage for "high burnup" spent nuclear fuel. Initial casks were loaded with spent fuel assemblies with uranium that had decayed for up to 10 years in pool storage. By 2010, utilities began to move radioactive waste more quickly from pools to casks, and the assemblies were generating more heat.

Dominion Virginia Power agreed to load a research cask with four different types of cladding (standard Zircaloy-4, low-tin Zircaloy-4, Zirlo, and M5), with a lid modified to permit sampling of temperatures and gases inside the cask. The cask will be stored on the pad at Lake Anna for up to 10 years before being shipped off-site to a research facility that will evaluate how the high burnup assemblies changed during drying and storage.19

transporting the empty TN-32B storage cask at North Anna for research

Source: WM2017 Conference 2017, Extended Storage of High Burn-up Fuel Cask R&D Project - 17145 (Figure 2)

The dry cask sites are located within the "protected areas" of a nuclear facility, surrounded by guards, fences, and other barriers. The recently-removed fuel assemblies that are still in wet pool storage are considered a greater risk. To guard against highly-radioactive waste being spread via a terrorist attack, the wet pool is located within the "vital area" of a nuclear plant, the portion with the reactor core, containment building, and generators and with a higher level of protection.20

dry casks can be stored in vertical positions, or placed horizontally in above-ground concrete bunkers similar to the way cars park in a garage

Source: US Nuclear Regulatory Commission, Typical Dry Cask Storage System

Casks on the pads are separated from each other according to a distance defined by Nuclear Regulatory Commission regulations to ensure no critical nuclear reactions will occur as the waste in each separate cask cools for thousands of years. By 2010, Dominion Virginia Power was planning to place the casks horizontally rather than vertically, an alignment designed to simplify future transport to the permanent repository.21

dry cask storage at Surry Nuclear Power Plant

Source: US Nuclear Regulatory Commission, Radioactive Waste: Production, Storage, Disposal (NUREG/BR-0216, Revision 2) (page 11)

In 2011, an earthquake with an epicenter in Louisa County moved 25 of the 27 casks then filled with radioactive waste at Lake Anna. Some casks shifted as much as 4.5 inches, but none were damaged. The utility and the Nuclear Regulatory Commission determined that leaving the casks in their new positions was safer than trying to restore the original gaps.22

dry casks with spent fuel assemblies are located within the secure, guarded area at Lake Anna Nuclear Power Station

Source: Cryptome, Lake Anna ISFSI

During the delay in licensing the site at Yucca Mountain, Nevada continued to object to its selection as a "national sacrifice area." US Senator Harry Reid became the Majority Leader of the US Senate when the Democratic Party took control of that body in 2006. The state increased its political influence by becoming an early primary site in 2008, and candidates for president became sensitive to Nevada's priorities.

In 2010, the now-influential Nevada delegation was able to get the Obama Administration and the US Congress to stop planning for the nuclear waste repository at Yucca Mountain. By that time, the volume of the spent nuclear fuel stockpiled at various nuclear power plants already exceeded the planned 70,000-metric-ton capacity of the repository. The Energy Department calculated that moving the backlog of high-level nuclear waste would require 24 years, assuming the repository could handle 175 train shipments annually. That would require one trainload every other day.

Finland build ts Onkalo permanent repository for spent fuel assemblies on Olkiluoto island, primarily because it offered the preferred geologic conditions 1,500 feet underground. Because three of the country's five nuclear power plants were on the island, transportation of the country's 5,500 tons of radioactive waste also was minimized.

Finland adopted the three-layer "KBS-3" concept for its nuclear waste disposal. Spent fuel assemblies were placed inside iron casks that were covered with a 2-inch thick layer of copper. In a dry environment, the copper was predicted to remain stable. The repository design was to place casks within individual holes drilled into the bedrock. Each cask was to be surrounded by bentonite clay, intended to keep the cask isolated from water.23

The Department of Energy placed the site in "cold standby," turning off the lights and ventilation in the underground tunnel. The Nuclear Regulatory Commission declared that power plants could store their high-level radioactive waste on-site for 60 years after shutting down a reactor.24

storage of spent fuel assemblies at nuclear power plants is supposed to be temporary, followed by transport to a permanent repository

Source: Government Accountability Office (GAO), Commercial Spent Nuclear Fuel: Congressional Action Needed to Break Impasse and Develop a Permanent Disposal Solution (Figure 2)

Senator Reid retired in 2016, but by that time Nevada was a swing state politically. Both Republican and Democratic candidates sought to win the state's six electoral votes in presidential elections, limiting the risk that any president would propose re-starting planning for a high level nuclear waste repository at Yucca Mountain.

In 2013, the Department of Energy re-started the challenge of choosing a new location, with three deadlines.

Yucca Mountain was isolated from any population center, and had geological formations that could isolate waste for thousands of years

Source: ESRI, ArcGIS Online

By 2021, a pilot interim storage facility was to be selected to store spent fuel moved from closed-down nuclear power plants, places where there were no active reactors to justify maintaining a high level of security. By 2025, a larger interim storage facility would be chosen so the Federal government could meet its contractual obligation to accept used nuclear fuel, and no longer be liable for paying the costs for utilities to continue on-site, at-reactor storage. By 2048, a permanent repository would be operational.

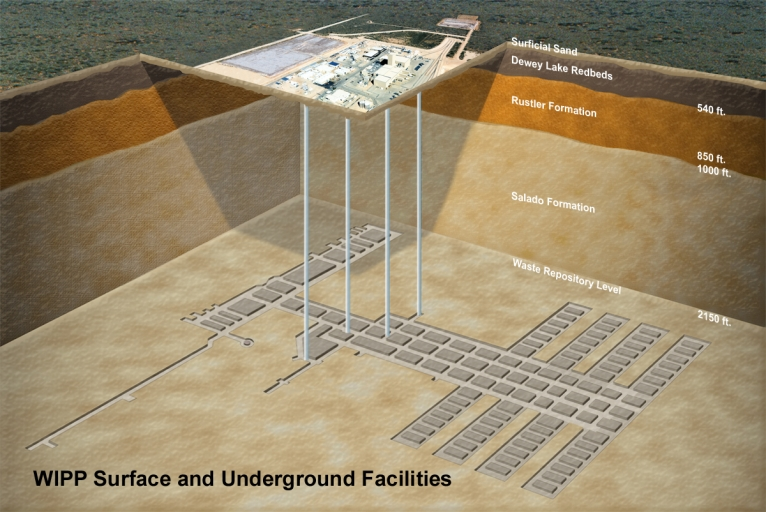

The strategy called for a consent-based siting process to minimize local opposition. The model was the creation of the Waste Isolation Pilot Plant (WIPP) facility in New Mexico, which stores transuranic wastes.

Transuranic wastes, often clothing and tools that has been in contact with radioactive materials, are hazardous but less-radioactive than spent fuel assemblies. The Waste Isolation Pilot Plant was constructed near Carlsbad in the 1980's. Department of Energy experts predicted the local salt beds would deform and fill the excavated spaces with wastes, keeping them isolated, but the key factor in the siting of the facility was community support. Unlike Nevada, New Mexico officials supported constructing a waste storage facility based on an expectation of new jobs.

low-level radioactive waste is buried underground in salt beds at the Waste Isolation Pilot Plant (WIPP) in New Mexico

Source: Department of Energy, Office of Environmental Management Taps Small Business for Waste Isolation Pilot Plant Contract

The Waste Isolation Pilot Plant began accepting transuranic wastes in 1999, and later plutonium that had been part of the US strategic stockpile. The Waste Isolation Pilot Plant remains the only repository for the permanent disposal of defense-related transuranic wastes, many of which were shipped from Department of Energy sites in Colorado, South Carolina, Idaho, and Washington associated with nuclear weapons research and development.

Only transuranic wastes created as part of the nuclear defense programs after 1970 are accepted at the Waste Isolation Pilot Plant. Disposal of spent fuel assemblies from nuclear power plants is not permitted, so the New Mexico facility is not a substitute for Yucca Mountain.

Operations at the Waste Isolation Pilot Plant were interrupted for two years between 2014-2016, after a truck caught fire and a barrel exploded and released radioactivity. Prior to arriving at the Waste Isolation Pilot Plant, the barrel had been filled with the wrong sort of clay to stabilize volatile radioactive chemicals. For those two years, the United States had no nuclear waste disposal facility for transuranic wastes. Until the New Mexico site was operational again, Department of Energy sites that generated transuranic wastes had operate like nuclear power plants and to store their wastes on-site or make short-term arrangements.25

The 2013 Strategy for the Management and Disposal of Used Nuclear Fuel and High-Level Radioactive Waste envisioned that one or more places in the United States would want the jobs associated with a facility designed to store high-level radioactive waste from power plants:26

Since planning for Yucca Mountain ended in 2010, no other state has indicated a willingness to accept high-level radioactive waste. No Virginia community is expected to volunteer "in expectation of the economic activity that would result."

A proposal to authorize mining the Coles Hill uranium deposit in Pittsylvania County revealed a local preference for economic growth based on agriculture, tourism, and education, and clear opposition in 2011-12 to uranium-based development. The Virginia Farm Bureau Business, Danville Pittsylvania County Chamber of Commerce, Danville City Council, town councils of South Boston and Halifax, Halifax County Supervisors, and local members in the General Assembly feared that uranium mining might release radioactivity, deterring visitors/students from coming to the area and limiting the public's willingness to buy items produced in the region.27

little space is required at the Lake Anna Nuclear Power Plant to store dry casks with spent fuel assemblies

Source: ESRI, ArcGIS Online

Failure to open the Yucca Mountain repository in 1998 left the Federal government accountable for disposing of high-level radioactive waste that it could not accept. The Nuclear Waste Policy Act in 1982 had imposed a $0.001 (one-tenth of a penny) fee per kilowatt-hour on nuclear plants, with funding directed towards the development of one or more Federal repositories for permanent waste storage.

The Nuclear Waste Fund collected $28 billion. Dominion Virginia Power paid $853 million, plus an additional $742 million in interest. After Yucca Mountain planning was stopped, utilities filed breach of contract claims. Federal courts ruled that the government must pay over $1 billion in damages and settlements; Dominion won a $112 million award.

The Department of Energy suspended fee collection in 2014.28

Virginia has less high-level radioactive waste stored at its two nuclear power plants than North Carolina and other southeastern states with more commercial reactors

Source: Nuclear Energy Institute, Used Nuclear Fuel Storage Map (as of end of 2015)

used, still-radioactive fuel assemblies will be stored above ground in dry casks "temporarily" at the Surry Nuclear Power Plant, until a national repository for permanent storage is developed

Source: Cryptome, Surry ISFSI

in 1986 the Department of Energy identified 20 potential locations east of the Mississippi River for permanent disposal of high-level radioactive waste, including three in Virginia

Source: Department of Energy, Area Recommendation Report for the Crystalline Repository Project (Figure 5-2)

high-level nuclear waste is stored "temporarily" at nuclear power plants and other sites across the country, including two power plants in Virginia

Source: US Department of Energy, Office of Civilian Radioactive Waste Management Image Gallery