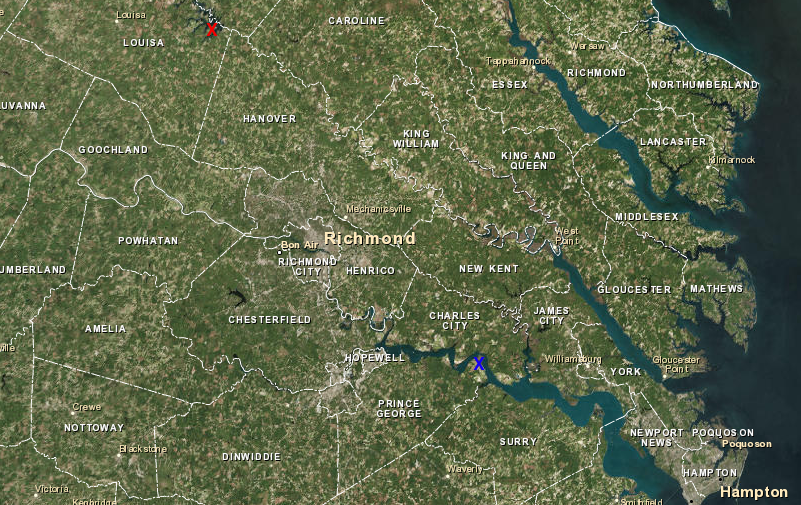

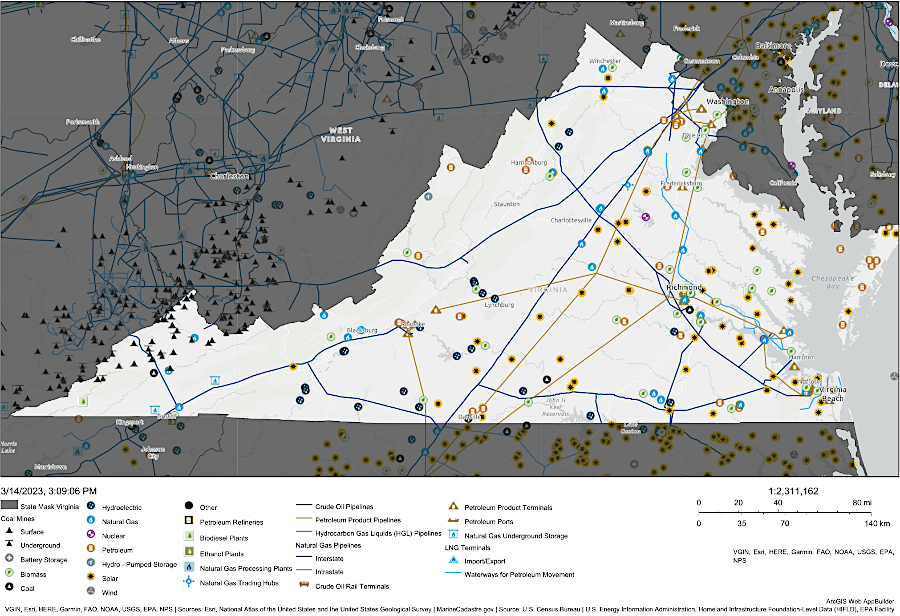

Virginia's four nuclear reactors are located at two sites, in Louisa County (red X) next to Lake Anna and in Surry County (blue X) next to the James River

Source: ESRI, ArcGIS Online

Virginia's four nuclear reactors are located at two sites, in Louisa County (red X) next to Lake Anna and in Surry County (blue X) next to the James River

Source: ESRI, ArcGIS Online

Virginia is not self-sufficient in producing the nuclear material that is used to create electricity and ionizing radiation. All the nuclear material used within Virginia is imported into the state. The Code of Virginia does not include any provisions that allow for mining or processing uranium ore yet, though a large uranium deposit is located at Coles Hill in Pittsylvania County.

The Virginia Department of Health regulates 17,000 radiation-producing machines. The most widespread use of nuclear material in Virginia is for medical services. Hospitals use radioactive isotopes, plus other nuclear material to generate X-rays and other ionizing radiation needed to scan body parts and treat cancer. X-ray equipment at dental offices relies upon Cobalt-60, and some engineering facilities also rely upon X-ray equipment to check the quality of welds. Construction firms rely upon nuclear gauges to test the density of soil, asphalt, and concrete.1

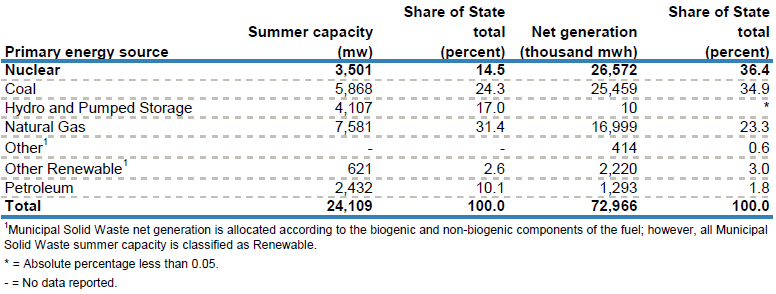

A different scale of safety planning, financial investment, and oversight is involved with reactors generating electricity via fission of U-235 atoms, compared to medical, engineering, and construction devices with relatively tiny amounts of nuclear material.

The US Army built two nuclear reactors at Fort Belvoir, and the University of Virginia and Virginia Tech built reactors for education, training, and research, but the main focus of nuclear energy in Virginia has been for generation of electricity.

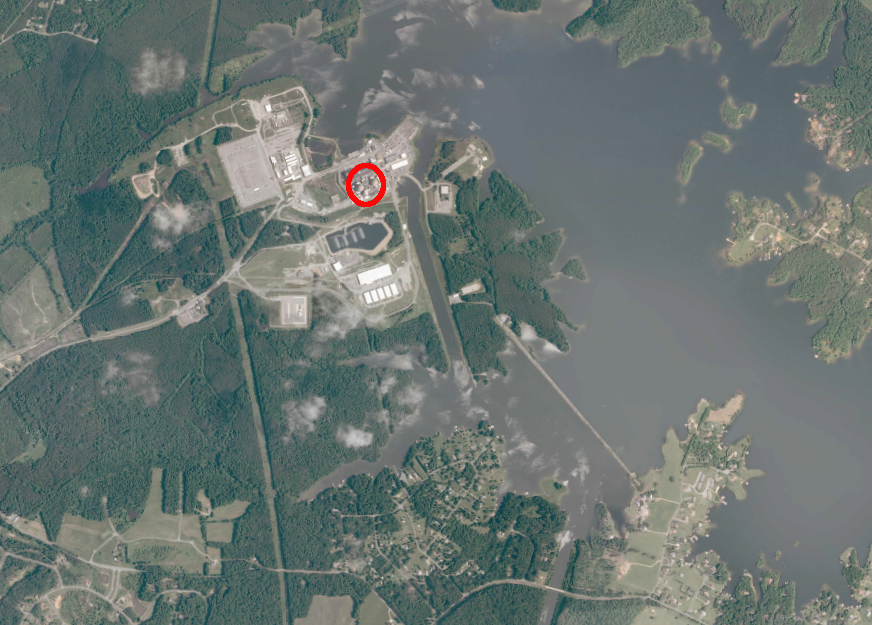

The investor-owned utility known now as Dominion Power has built a total of four reactors at two sites. Two reactors are located on Hog Island peninsula in Surry County (Surry 1 and Surry 2, started in 1972 and 1973) are capable of generating a total of 1,638 megawatts. Two nuclear reactors in Louisa County (North Anna 1 and North Anna 2, started in 1978 and 1980) are capable of generating a total of 1,863 megawatts.

nuclear power plants were built at locations with adequate cooling water

Source: Nuclear Regulatory Commission, North Anna and Surry, Power Stations - License Renewal Application

Surry nuclear power plant (through car windshield)

Both sites were isolated from large population centers, which provided a measure of safety in case of any form of nuclear incident. As reactors were built acoss the country, eventually 1/3 of the American population ended up living within 50 miles of one.

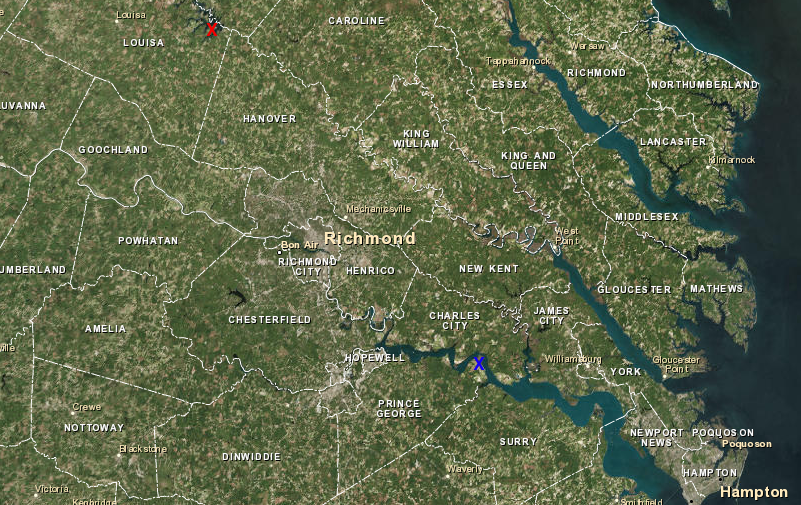

The Surry and North Anna sites offered access to enough water to cool the nuclear fuel containers. Fission generated the heat needed to boil water in a secondary system into steam, which was used by conventional steam turbines to generate electricity.

all of Virginia's military and commercial reactors have used the pressurized water design

Source: Army Engineer History, Nuclear Power Generation

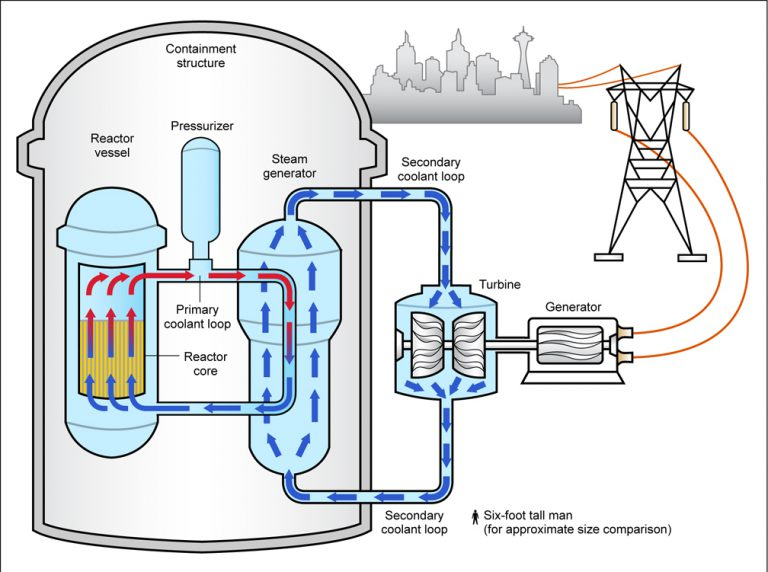

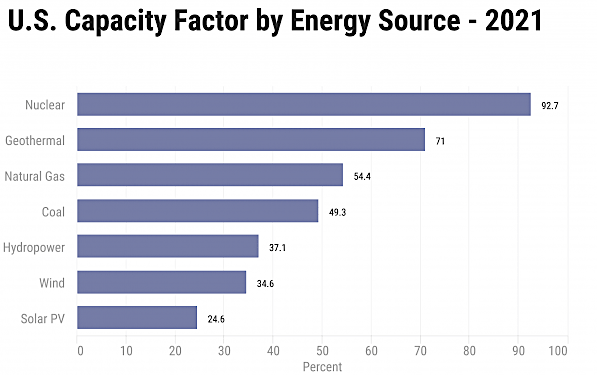

The reactors are most efficient when running at a steady rate, so they are used for baseload rather than peaking power. Baseload plants run 24 hours per day and supply the electricity needed even when demand is at its lowest level. In contrast, peaking plants are turned on and off during the day, and supply extra energy needed in the morning (when people wake up, get ready for work/school, and turn on lights/hairdryers etc.) or in the evening (when people come home and cook dinner, do laundry, etc.)

power lines headed south from Surry nuclear power plant

In 2017, 41% of the electricity generated in Virginia was produced by the four nuclear reactors at North Anna and Surry. Nuclear reactors total just 23% of the potential generating sources in Virginia, but produced a higher percentage of the state's electricity because the reactors run steadily. Other generators are used only intermittently for peaking power.2

Virginia total electric power industry, summer capacity and net generation, by energy source, 2010

Source: U.S. Energy Information Administration, State Nuclear Profiles 2010

Before the development of solar panels, nuclear reactors produced the lowest-cost electricity. Back in 1954, the chair of the Atomic Energy Commission predicted that nuclear power plants could generate electricity at such a low cost that it would be "too cheap to meter."

That did not come true; construction of almost every large nuclear power plant was plagued by cost overruns. In 1974, climbing interest rates made it too expensive to borrow the massive amount of dollars required to construct a large nuclear power plant. For the next 34 years, no more were ordered by utilities. Dominion Power has the option of proposing a third reactor at North Anna, but the traditional design process for such facilities involves high costs and financial risks.

The first of a pair of new 1,100-megawatt nuclear reactors came online in 2023 at the Vogtle nuclear power plant in Georgia, creating the largest nuclear-generating complex in the United States. They may end up being both the first and last nuclear commercial reactors to be fully licensed by the U.S. Nuclear Regulatory Commission, unless Dominion Power pursues licensing of a third reactor at North Anna. All other reactors in the United States were approved prior to creation of the complex licensing process by that Federal agency.

Market forces are driving utilities to obtain electricity from other, more cost-effective generation sources. These include natural gas, renewables, and a new form of nuclear power created by small modular reactors.

2023 energy infrastructure in Virginia includes non-nuclear sources, plus potentially small modular reactors in the future

Source: U.S. Energy Information Administration, Interactive GIS Data Viewer

In 2011, Virginia Dominion Power compared the various costs of the primary sources of electricity in Virginia:3

nuclear - 0.6 cents per kilowatt hour

coal - 3.5 cents per kilowatt hour

combined cycle (natural gas) - 4.5 cents per kilowatt hour

Lake Anna was built in 1971 to provide cooling water for nuclear reactors - note channel next to (circled) reactors

Source: U.S. Geological Survey (USGS), Lake Anna West 7.5x7.5 topographic quadrangle (2010)

Lynchburg, Bedford and Newport News are the focal points in Virginia for technical nuclear support services, plus construction of nuclear fuel assemblies and other power plant components. Hopes for industrial growth based on the nuclear power industry have been dashed by the failure of utilities to manage cost and safety issues. Without construction of new nuclear power plants, and with the retirement of existing plants, the future of nuclear support services is limited. The most reliable business in the industry is servicing reactors for nuclear-fueled ships operated by the US Navy.

The largest concentration of nuclear reactors in Virginia is the US Navy fleet of surface ships and submarines in Hampton Roads. The number of nuclear reactors in Virginia fluctuates, as ships come and go into different bases there. The Navy has a major nuclear power program in Virginia, installing and refueling small nuclear reactors in aircraft carriers and submarines on the northern bank of the James River.

Newport News Shipbuilding manages the defueling of nuclear reactors in warships. The US Navy scheduled a shift in homeports for the USS Nimitz in 2026, from Bremerton (Washington) to Norfolk, in preparation for decommissioning the oldest aircraft carrier in the fleet. Huntington Ingalls Industries, which owns the shipyard in Newport News, won the contract to remove the reactors from the 50-year old ship.

Newport News Shipbuilding:4

the US Navy has the largest number of nuclear reactors in Virginia at Norfolk, Portsmouth, and Newport News

Source: Wikipedia, Naval Station Norfolk

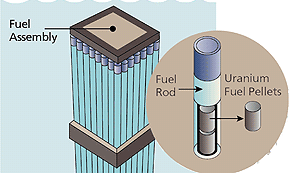

In 1955, when Babcock and Wilcox decided to make equipment for nuclear plants in Campbell County, the area was a center of foundries and manufacturing (especially shoes). Workers had the technical expertise needed by the new industry. Babcock & Wilcox completed the Mount Athos Nuclear Fuel Plant in 1956.

Between 1969-2011, the facility received pressed U02 pellets, placed them into rods and nuclear fuel assemblies, and shipping the assemblies to nuclear power plants. Between 1975-1982, it also created pellets from U02 powder. After closing down the pelletizing operation, the equipment was disposed as low-level radioactive waste and the area was decontaminated so it could be used for creating fuel assemblies.

In 2011, when Areva was the owner, the company decided not to renew its license from the Nuclear Regulatory Commission for production of fuel assemblies in Lynchburg. It shifted to production in Richland, Washington, and decontaminated the production line at Lychburg.5

Areva, a French multinational group, later placed its "Operational Center of Excellence for Nuclear Products and Services in North America" in Lynchburg. Areva upgraded its commitment to the area in 2013, committing to invest another $26 million for technical services and machinery.

Nuclear power plant trainees, including some from France and Germany, practiced operations such as welding underwater there. A "shake table" enabled testing reactor responses to earthquakes. The governor of Virginia formally welcomed the company's growth with a speech in 2014 that declared:6

Babcock & Wilcox split in 2015, and BWXT retained the nuclear business. in 2023, BWXT was the lead contractor on a successful bid to clean up the site of the Hanford Site Tank Farms in the state of Washington. The Federal government produced plutonium there between 1943-1987. The contract, worth potentially $45 billion, requires moving low-level radioactive waste to a facility where it will be encased in glass through vitrification.

The company still compresses uranium powder into pellets and loads the pellets into tubular fuel rods. It operates a Category 1 Fuel Fabrication Facility in Lynchburg that fabricates all fuel assemblies, the cores of reactors, for the US Navy's nuclear submarines and aircraft carriers. In 2020, it had nearly $4 billion in contracts with the US Government to manufacture nuclear propulsion systems for warships.

The BWXT facility was one of just two non-government facilities licensed to possess and process highly enriched uranium in the United States. By 2023 the other, Nuclear Fuel Services (NFS) in Erwin, Tennessee, was also owned by BWXT. That facility near Oak Ridge had been producing nuclear fuel containing both high-enriched and low-enriched uranium since 1959.7

The company had plans to expand its nuclear operations and technical services group to include manufacturing new reactors that would require less capital investment for constructing new nuclear power plants. That business opportunity is challenging, with little demand and wavering support from state and Federal agencies.

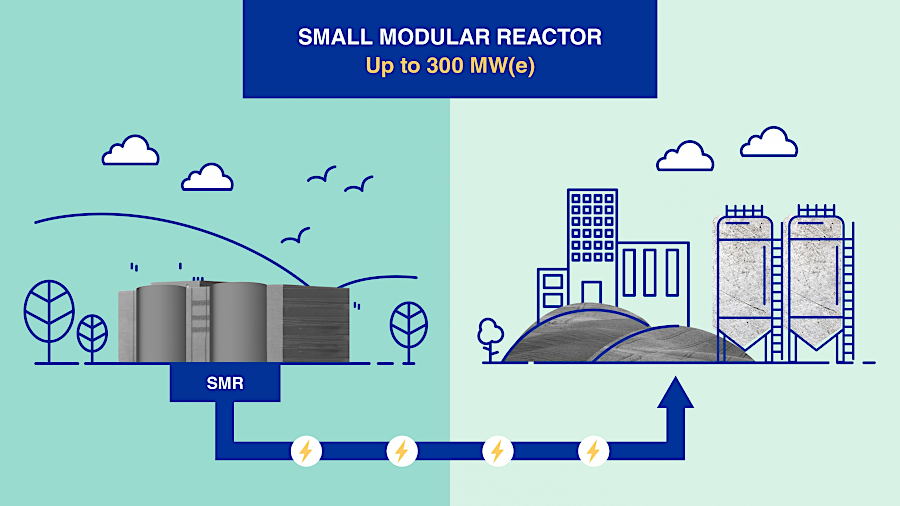

The "small modular reactor" program developed by Babcock & Wilcox, before splitting off BWXT in 2015, was based on the mPowerTM design. The company bet that the future of traditional, massive 900+MW nuclear power plants would be limited because of the extraordinarily high costs for initial construction. Utilities face enormous financial risk with such plants. They must borrow money and repay the bonds, even if a nuclear plant is not completed or is closed before its intended lifespan for safety reasons.

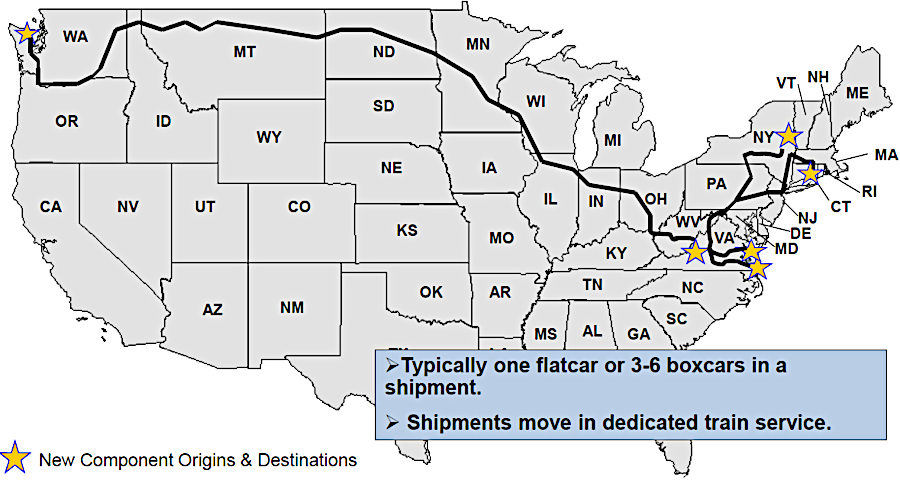

Babcock & Wilcox projected a bright future for generating electricity using nuclear reactors by advocating a different strategy. It proposed that new nuclear plants should be assembled in individual 50MW-300MW modules, built according to a standardized design in centralized factories to obtain the economies of scale. Modules would be shipped to the final site of the power plant, then buried underground when the radioactive fuel is added.

Separate modules would be funded individually, reducing the financial risk to an acceptable level for investors and state regulators. The low cost, with high reliability to produce electricity to meet baseload demand 24/7, could overcome public objections to constructing new nuclear power plants.

Engineers at the Center for Advanced Engineering and Research, an industry-led research center in Bedford, prototyped this dramatically different approach with a scale model, built above ground for testing. Babcock & Wilcox also used its facilities in Lynchburg for simulating operations in the future mPower control room, and for managing nuclear fuel.

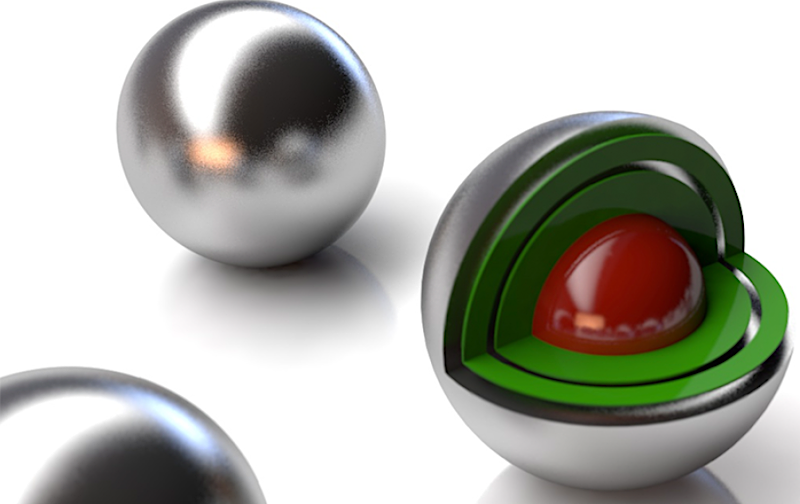

uranium fuel pellets are encased in metal rods, which are then bundled together to create a fuel assembly

Source: Nuclear Regulatory Commission, Fact Sheet on Storage of Spent Nuclear Fuel

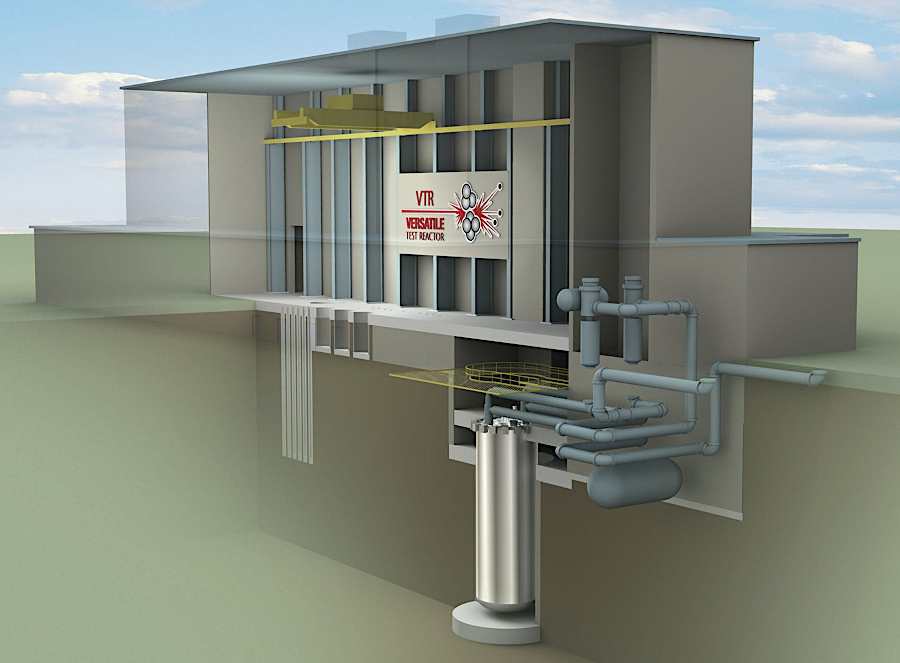

In 2013, the Department of Energy awarded grants for design, development, and ultimately construction of up to six new small modular reactors, providing 180 megawatts each, at the former Clinch River Breeder Reactor (CRBR) site in Oak Ridge, Tennessee. Commercial operations were projected to start in 2022, but that was overly optimistic.

As described by the Department of Energy:8

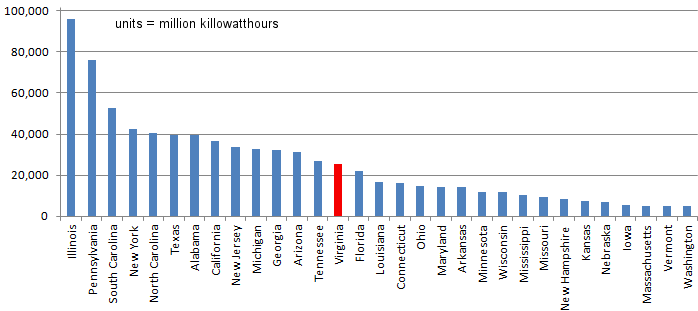

13 states consumed more nuclear-generated kilowatts of electric power than Virginia in 2011,

while 36 states consumed less (19 states consumed no nuclear power)

Data Source: US Energy Information Administration, Table F23: Nuclear Energy Consumption, Price, and Expenditure Estimates, 2011

Based on Babcock & Wilcox's mPower design, US Department of Energy and Lynchburg officials hoped to create a US-based manufacturing center for constructing self-contained nuclear power plants. The small modular reactors (SMR's) would then shipped as via truck, to be assembled and installed in locations across the United States and in other countries.

Babcock & Wilcox failed to make sales of mPower reactors to other customers, or to attract other investors besides the Department of Energy willing to finance the research and development costs. In 2014, the company announced it was cutting funding for mPower by 75%, and laying off over 10% of its employees in central Virginia. The $30 million Integrated Systems Test facility, built by Babcock & Wilcox at the Center for Advanced Engineering and Research to simulate accidents and test new equipment at nuclear power plants, was shut down.

In 2016 the Tennessee Valley Authority announced it would apply for a permit to install small modular reactors (SMR's) at the Clinch River site. Bechtel committed to partner with BWXT, the portion of Babcock & Wilcox that retained the nuclear business, to develop a 195-megawatt modular reactor. That breathed new life into the small modular reactors program. However, in 2017 Bechtel and BWXT announced they were cancelling the mPower program.

Babcock & Wilcox paid Bechtel $30 million to cancel the mPower partnership, saying:9

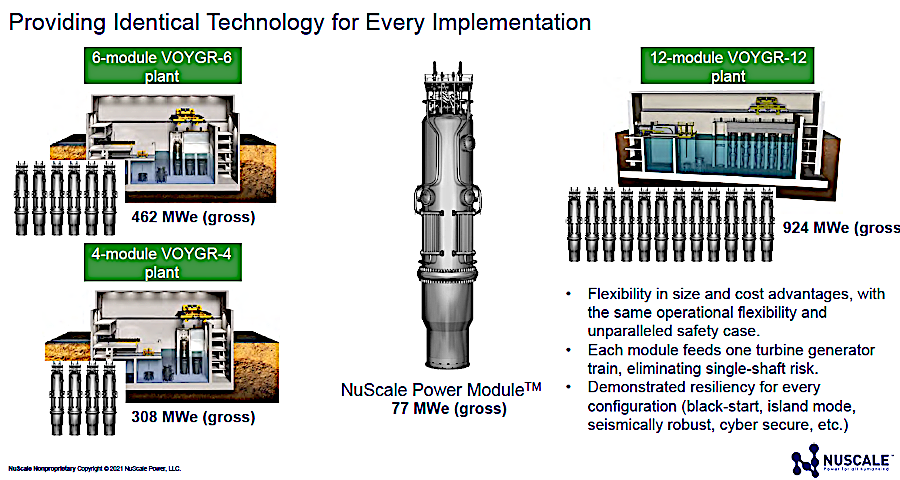

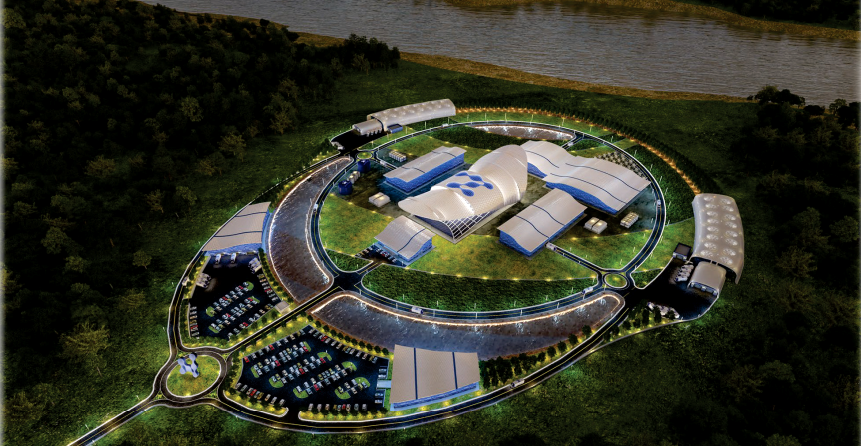

NuScale continued research into small modular reactors, each producing 77MW of electricity and costing around $200 million to build. Small modular reactors may generate a higher volume of radioactive waste, compared to reactors in conventional nuclear power plants, if "neutron leakage" will activate more metal surrounding the larger number of small fuel assemblies.

In 2018, NuScale selected BWXT to do the engineering work for a small modular reactor using a light water design. In 2022, the U.S. Nuclear Regulatory Commission (NRC) certified the design of NuScale's 77-megawatt VOYGR power module. However, in 2023 NuScale cancelled its contract with Utah Associated Municipal Power Systems, a consortium of municipal utilities, to build the Carbon-Free Power Project at the Idaho National Laboratory.

The project was supposed to include six of the company's 77-megawatt reactors, creating a 462-megawatt power plant. NuScale was unable to triple the number of customers, an increase required to cover the rising costs. The initial project cost had increased 75%, from $5.3 billion to $9.3 billion. The projected price of electricity had grown from $58 per megawatt-hour to $89 per megawatt-hour due to inflation and higher interest costs.

NuScale remained the only U.S. developer with a small modular reactor (SMR) design approved by the Nuclear Regulatory Commission until December 2023, when Kairos Power LLC was authorized to build a $100 million demonstration reactor in Tennessee. Its Hermes design uses molten fluoride salt as a coolant. If successful, the Hermes 2 project then would construct two reactors generating a total of 28 megawatts of electricity.

Having a regulatory head start was a financial advantage, but no guarantee of continuous investor support. Cancelling the Carbon-Free Power Project triggered another 20% drop in the value of NuScale stock. The company's stock dropped from $14.87/share in August 2022 to $2.08/share in November 2023, reflecting the risks associated with commercializing small modular reactors.

In 2023, NuScale was chosen to provide carbon-free, baseload energy to planned data center complexes in Ohio and Pennsylvania. The plan was to construct 24 units of 77-MWe (megawatts electric) VOYGR module. The "small" in such small nuclear reactors was significant. NuScale claimed only 32 acres were needed for a VOYGR-12 module to generate 77MW, compared to 17 square miles for solar panels.

Small modular reactors are already in commercial operation. In 2019 Rosatom, a Russian state corporation, placed into service two small modular reactors on the Academik Lomonosov barge. The floating nuclear power plant provides 70 megawatts of electricity to Pevek in Russia. NuScale and Rosatom are now competing to win contracts to build small modular reactors in multiple countries.

China connected the first onshore small modular nuclear reactor to the grid in December, 2021. The Linglong One design is for a high-temperature gas-cooled reactor, which heats helium instead of water. The first to go into use was built at Shidao Bay in Shandong province.

In 2023, a partnership of construction and energy companies signed the first commercial contract for a grid-scale small modular reactor in North America. The consortium committed to build a small modular reactor in Ontario, Canada, with completion by the end of 2028. The BWRX-300 light water design was developed by GE Hitachi Nuclear Energy (GEH).

Despite reactor meltdowns, the challenge of disposing of radioactive waste, and the low costs of solar and wind energy, nuclear power plants could remain part of the electricity generation mix as the primary baseload source. The nuclear-focused companies based in Lynchburg might have an expanding market for business.10

NuScale highlights the flexibility of modular design, with each module powering one turbine generator

Source: US Department of Energy, NuScale Power Overview Future Vision of Nuclear R&D Webinar - SMR (February 15, 2022)

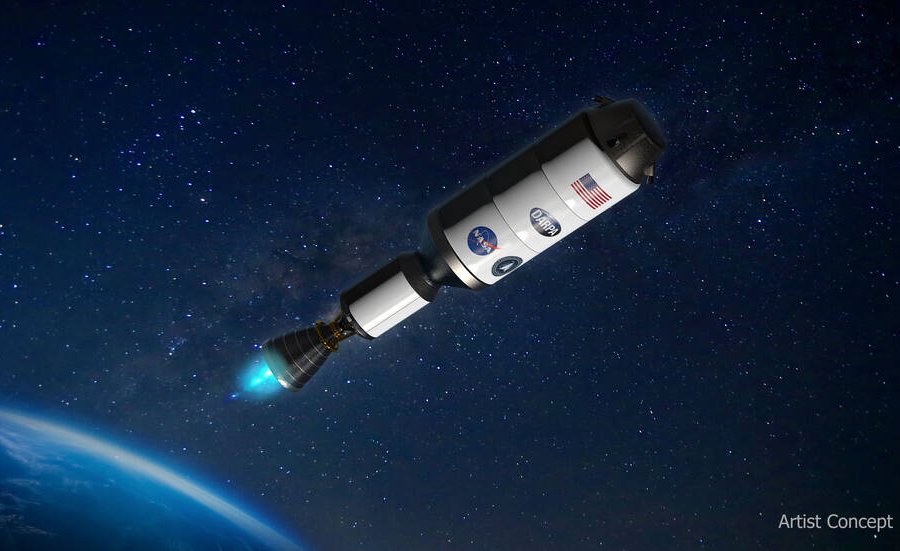

The National Aeronautics and Space Administration (NASA) offered another potential market for nuclear reactors designed by BWXT in Virginia. Rockets powered by nuclear thermal propulsion have the potential to provide more thrust than rockets powered by chemical fuels and oxidizer, cutting in half the amount of time astronauts must spend in space to reach Mars. A faster rocket would reduce the exposure time of astronauts in space, and a nuclear engine would allow military satellites to remain in orbit longer and evade attack.

BWXT won the contract in 2023 to construct and install the fuel in a nuclear reactor for the planned 2027 launch of the Demonstration Rocket for Agile Cislunar Operations (DRACO). Once safely in space, the fission process in the reactor would be initiated to heat liquid hydrogen.

The nuclear fuel would provide heat; the gas would provided thrust. The objective was to cut the time required for a trip to Mars from 6-9 months, using traditional chemical fuels, down to as little as 2.5 months. A nuclear thermal propulsion system about the size of a 55-gallon drum would require materials that could withstand temperatures around 4,000°F. At its Lynchburg facility, BWXT already uses furnaces that reach 4,000°F to heat-treat materials.

In 2023, BWXT also won a contract with the US Air Force to supply nuclear fuel for a reactor to provide both thrust and electricity for orbiting spacecraft. The Joint Emergent Technology Supplying On-Orbit Nuclear (JETSON) program was intended to allow satellites to operate without solar panels, and to provide more electricity than traditional solar panels.

The NASA Administrator told an audience at Liberty University in 2020:11

a nuclear reactor to power rockets in space will be constructed and fueled in Lynchburg

Data Source: National Aeronautics and Space Administration (NASA), NASA, DARPA Will Test Nuclear Engine for Future Mars Missions

AREVA also produced fuel assemblies for nuclear power plants in Lynchburg until 2011. In 2009, AREVA and Huntington Ingalls Industries broke ground on a plant in Newport News that would manufacture major, heavy components for AREVA's EPRTM pressurized water reactor, with plans to start manufacturing in 2012. Fundamental to that planning was the assumption that new nuclear power plants would be constructed in North America.

nuclear fuel assemblies are not handled as radioactive waste, when transported to Newport News for installation in aircraft carriers

Data Source: US Nuclear Waste Technical Review Board, Naval Spent Fuel Transportation

In 2010, AREVA and Huntington Ingalls Industries stretched out the deadlines. AREVA stopped production of the plant in Newport News in 2011, after construction of the Calvert Cliffs 3 reactor in Maryland was delayed and then followed by the Fukushima Daiichi nuclear disaster in Japan.

AREVA also closed down its fuel fabrication facility in Lynchburg, which had been manufacturing fuel assemblies for nuclear power plants. The process required uranium hexafluoride (UF6) to be heated into a gas and converted chemically into uranium dioxide (UO2) powder. That powder was pressed and heated to form a ceramic pellet, the pellets were loaded into metal tubes, and tubes were clamped together to create fuel assemblies.

After 2011, uranium contamination at AREVA's Category 3 Fuel Facility was cleaned up and the license from the Nuclear Regulatory Commission was terminated. That left just three Category 3 Fuel Facilities in the United states - Global Nuclear Fuel-Americas (Wilmington, North Carolina), Westinghouse Columbia Fuel Fabrication Facility (Columbia, South Carolina), and Framatome, Inc. (Richland, Washington)

Five years later, Westinghouse tapped into the manufacturing capacity at Newport News Industrial, a subsidiary of the Huntington Ingalls Industries shipyard. Westinghouse had contracts to install its AP1000 pressurized water reactor at new nuclear plants in Georgia and South Carolina. The ability to manufacture large ships was suitable for constructing the steel components needed for shielding nuclear reactors.12

Plans for the nuclear industry's growth were excessively optimistic. Construction of the new nuclear plants in South Carolina was cancelled after costs far exceeded estimates. Westinghouse went into bankruptcy, and AREVA fragmented and moved its headquarters to Charlotte. In 2018, the company moved back to Lynchburg and rebranded itself as Framatome. That was the name which had been used in Lynchburg until 2006, when Areva purchased the business.13

In 2020, Framatome purchased BWX Technologies' commercial nuclear services business.

Framatome consolidated staff and research at its Lynchburg building on Old Forest Road in Lynchburg It signed a contract with Dominion Energy in 2021 to continue support of the company's reactors, including refueling services at the North Anna and Surry plants.As part of its 2020 deal, Framatome sold its land and advanced manufacturing building on Mount Athos Road to the adjacent property owner, BWX Technologies. The new owner branded the former Framatome site as the BWXT Innovation Campus. In the transactions, BWX Technologies (BWXT) pivoted away from support of large nuclear power plants, and chose to focus on advanced technologies for space power, microreactors and medical radioisotopes.

In 2021, BWX Technologies won a contract worth up to $21 billion from the Energy Department for environmental management at the Savannah River Site in South Carolina. Previous expansion plans for the BWXT campus, intended to relocate 150 employees from nearby facilities, were modified because almost 100 new employees making an average annual salary of $115,000 would be hired.

BWXT did not dispose of its business units that created fuel assemblies; it retained that profitable work. In 2023, its Nuclear Fuel Services component in Erwin, Tennessee won another contract from U.S. Naval Nuclear Propulsion Program to manufacture nuclear reactor fuel. The fuel is shipped from Tennessee to Lynchburg, where it is installed in reactors made by BWXT for use on submarines and aircraft carriers.

Only BWXT was licensed by the US Nuclear Regulatory Commission to store and process highly enriched uranium (HEU), used to power nuclear reactors in US Navy ships.

In 2021, the company won a US Department of Energy contract to build a production line to manufacture uranium-molybdenum alloy High Assay Low Enriched Uranium (U-Mo HALEU) fuel, which s enriched beyond the 5% standard used in traditional nuclear reactors. The higher percentage of uranium, up to 20%, is required to power small modular reactors. The Department of Energy agreed to provide two tons of uranium scrap, primarily from the Y-12 National Security Complex in Oak Ridge, as feedstock. Final product created at BWXT's Lynchburg facilities will be HALEU feedstock in an oxide form, at an enrichment level of 19.75%.

In 2023, the Nuclear Regulatory Commission licensed the Centrus Energy facility in Piketon, Ohio. It began operations later that year, becoming the first American uranium enrichment plant to start operations since 1954. That began to break the monopoly of Rosatom to sell HALEU commercially. Centrus Energy chose BWXT to construct 16 centrifuges and build a "cascade" to enrich uranium and create high-assay low-enriched uranium (HALEU).

BWXT has produced tristructural isotropic (TRISO) particle fuel since 2003. When it won a contract for the U.S. Department of Energy in 2020, a news story noted:14

BWX Technologies purchased land/building from Framatome (red X) and established the BWXT Innovation Campus on Mount Athos Road

Source: Campbell County, Parcel Data Viewer

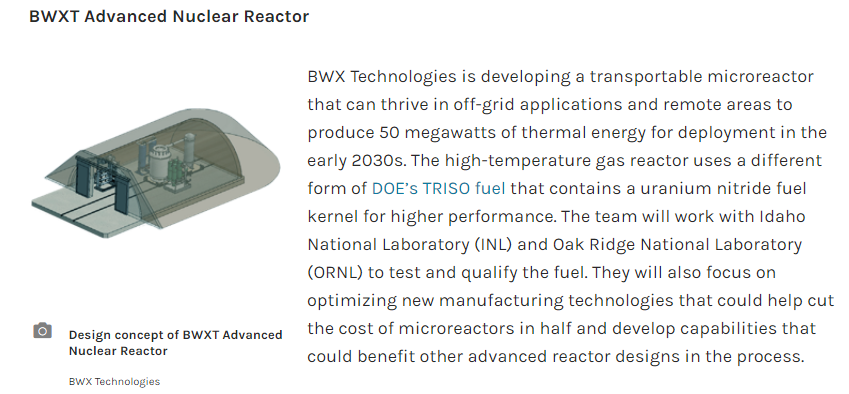

The microreactor efforts of BWXT Advanced Technologies won Federal government support. In 2020, BWXT was selected by the Department of Energy as the lead contractor to design a microreactor in partnership with partner with Idaho National Laboratory and Oak Ridge National Laboratory. The Federal agency chose the Virginia company as one of five to create different designs for the Advanced Reactor Demonstration Program.

The high temperature, gas-cooled microreactor was designed to meet the Department of Energy's priority to provide portable, carbon-free electricity. Other Department of Energy priorities, not pursued by BWX, were to create an advanced reactor demonstration leading to a fully functional advanced nuclear reactor within seven years and to propose advanced reactor concepts that could be used to create commercial reactors in the mid-2030s.15

BWX Technologies purchased land/building from Framatome (red X) and established the BWXT Innovation Campus on Mount Athos Road

Source: US Department of Energy, 5 Advanced Reactor Designs to Watch in 2030

In 2021, the company was one of two finalists in "Project Pele," sponsored by the Department of Defense, to create a final prototype design for a transportable nuclear microreactor to power military installations and potentially forces deployed in the field. A mobile microreactor capable of producing 1-5 megawatts of electrical power (MWe) could dramatically reduce the need to transport fuel to forward military bases, such as those established during the wars in Iraq and Afghanistan.

There could also be civilian uses:16

the military plans to transport a microreactor to forward bases, reducing the need to ship diesel fuel

Source: US Department of Defense, Construction and Demonstration of a Prototype Mobile Microreactor - Environmental Impact Statement, Volume 1 (Figure 2.3-7)

In 2022, BWXT started producing TRISO fuel particles. They were the size of poppy seeds, with three layers of carbon and ceramic materials surrounding pellets of uranium that had been enriched to a level four times higher that standard reactor fuel. The coatings were designed to capture fission products from the U-235 in the pellets. Each particle was manufactured with its own containment system for trapping radioactive waste and preventing a fuel meltdown, if a reactor had inadequate cooling capacity.

A major competitor in the production of TRISO pellets was Standard Nuclear based in Oak Ridge, Tennessee. In 2025, the US Department of Energy selected Standsrd Nuclear to be the pilot company with te first Federal authorization for making TRISO fuel pellets.

Nuclear industry leaders planned to replace the standard production of fuel cores for warships and traditional nuclear reactors with new designs based on new types of fuel. A ban on the import of enriched uranium from Russia was scheduled to go into effect in 2028, so the supply chain for nuclear power plants had to change.

BWXT faced intense competition in the business of making TRISO fuel for Small Modular Reactors, for which many orders were expected in the 2030's. Plans for new data centers caused the demand for electricity to skyrocket. In addition, the military anticipated adding Small Modular Reactors on multiple bases to provide a reliable source of electricity, independent of the vulnerable transmission grid outside the bases boundaries.

TRISO pellets are triple-coated with carbon and silicon carbide so they will not melt at the temperatures which will occur in a Small Modular Reactor, even without cooling capacity

Source: US Department of Energy, TRISO Particles: The Most Robust Nuclear Fuel on Earth

The higher level of enrichment in TRISO fuel generated hotter temperatures, allowing for more compact and efficient reactor design. National Aeronautics and Space Administration (NASA) was interested in using TRISO fuel to power facilities on Mars and for the Space Nuclear Propulsion (SNP) project to create a nuclear thermal propulsion system.

In 2022, BWXT also won the $37 million contract to manufacture a core for Project Pele. That contract required building a prototype and deliver it to the Idaho National Laboratory. The plan was to build the microreactor components in Lynchburg and Euclid, Ohio, then deliver them to the Idaho National Laboratory (INL) for several years of testing. The Defense Department expected to transport the Generation IV nuclear reactor in four 20-foot shipping containers to Idaho National Laboratory in 2026.

As described in World Nuclear News:17

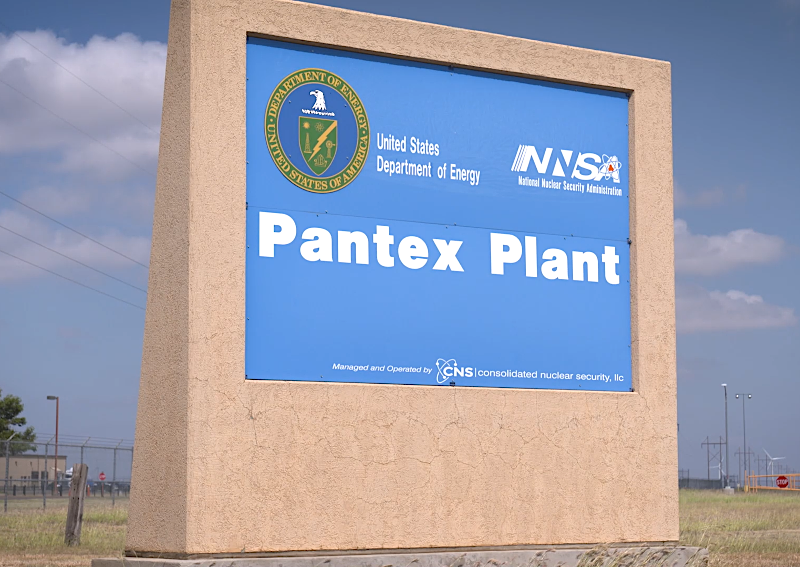

In 2024, BWXT and two other partners won a contract to manage the US Department of Energy's nuclear weapons stockpile in Pantex, Texas, where atomic bombs are assembled/disassembled and plutonium "pits" at the heart of nuclear weapons are stored. If the contract is renewed for three 5-year options, over 20 years it could be worth a total of $30 billion.

In 2025, BWXT won a $2.1 billion contract from the Naval Nuclear Propulsion Program to supply nuclear reactor components for Columbia and Virginia class submarines and Ford class aircraft carriers. The company's facilities in Lynchburg and Erwin, Tennessee are the only two sites that the Nuclear Regulatory Commission has licensed to store and process highly enriched uranium.18

BWXT won a contract in 2024 to manage the nuclear weapons that are assembled and dismantled in Pantex, Texas

Source: US Department of Energy, History

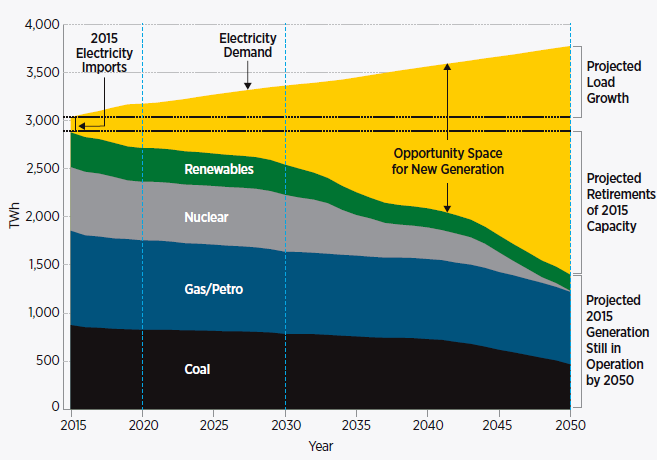

After adoption of the Paris Climate Accord in 2015, the focus on reducing greenhouse gas emissions created a new opportunity for commercial nuclear reactors based on a different design. Utilities and government agencies were no longer willing to build massive nuclear power plants which cost billions of dollars and were high-risk investments, with inevitable cost-overruns during construction and changing licensing requirements. The Nuclear Energy Institute estimated that 300 Small Modular Reactors would be operating by 2050.

The diversity of new designs was expected to create new business opportunities for BWXT Advanced Technologies. Growing demand for fuel assemblies was expected to be sufficient to justify selling the relatively safe nuclear services business to Framatome, its next-door neighbor in Lynchburg.

Bill Gates saw the opportunity to use standardized microreactors to create electricity with almost zero emissions, once a reactor was installed. Gates started TerraPower in 2008, and it has pursued a design based on using molten salt to cool the reactor. TerraPower plans to build its first "Natrium" reactor at Kemmerer, Wyoming, where it will replace a coal-fired power plant.

Because the TerraPower design using molten salt was different from already-licensed light-water reactors, getting a license from the U.S. Nuclear Regulatory Commission will require extra time compared to NuScale Power's small modular reactor design. TerraPower, like developers of other small modular reactors, also ran into a roadblock in acquiring nuclear fuel.

The original source of HALEU fuel was to be Russia, but that supply was no longer available after Russia invaded Ukraine in 2022. As a result, the reactor completion date was pushed back two years from 2028 to 2030.

They will provide the nuclear energy to power most small modular reactor designs. Traditional large light-water nuclear reactors in the United States use uranium enriched to only 5% uranium-235, categorized as low enriched uranium (LEU) fuel. The small modular reactors are designed to use pellets enriched with between 5-20% of uranium-235, classified as high-assay low-enriched uranium (HALEU). The smaller reactors need more energy in a smaller volume to generate cost-effective electricity.

In contrast, US Navy and British submarines use fuel enriched to 93.5% uranium-235, which is weapons grade material. Submarines of Russia and India use nuclear fuel enriched to no more that 20% uranium-235. Reactors in nuclear submarines of China and France use low enriched uranium (LEU).

The United States is studying how a new reactor design could power ships using high-density, low enriched uranium (LEU) fuel. Shifting away from weapons-grade highly enriched uranium (HEU) would enhance the nonproliferation agenda by eliminating the justification for other countries to create reactor fuel that could also be used in atomic bombs. Eliminating production of highly enriched uranium in the United States would also reduce the risk of theft and diversion to terrorists.19

TerraPower developed a new reactor design that did not require a cooling tower

Source: TerraPower, About Us

Advocates for developing new designs and building new nuclear power plants claimed that they would generate electricity without creating greenhouse gases, and would reduce the safety risks by using passive techniques for cooling the reactor. In case of a problem, reactors would not overheat even if they lost all power for maintaining the cooling system.

nuclear reactors in Virginia do not have iconic cooling towers, but instead discharge heated water into Lake Anna (above) and the James River

Source: ESRI, ArcGIS Online

When electrical power was cut off to nuclear power plants cooled by water, reactors began to overheat after the water circulation stopped. Diesel generators were included in power plant designs to maintain the cooling water systems until power could be restored, but at Fukushima a tsunami destroyed the diesel backup system. Three reactor cores melted through the containment vessels in Japan, and pressurized hydrogen gas explosions destroyed the outer containment buildings.

There have been eight core-melt accidents in military and civilian reactors since 1952, including experimental reactors. Three separate events caused core-melts in nuclear power plants generating electricity between the incident at Three Mile Island in 1979 and Fukushima in 2011, averaging almost one per decade.

Despite the expensive safety systems, by one calculation a full or partial meltdown should be expected every six to seven years. A 2016 article in the Bulletin of the Atomic Scientists, after the Fukushima disaster, estimated the likelihood of another core-melt accident:20

New designs, using cooling techniques that would be effective even if the reactors lost electricity needed to pump water, sought to prevent such a disaster. The new designs were also intended to be uranium-efficient, generating more electricity from fuel rods before they had to be replaced.

High-level nuclear waste would still be produced by any new sodium-cooled fast reactors, high-temperature gas-cooled reactors, and molten salt-fueled reactors. No permanent repository for storage is available yet for new high-level radioactive material.

The cost risks also remained high, even without accounting for the disposal of high-level nuclear waste. Since no actual small modular reactors had been constructed in the United States according to any design, the economic viability of any specific project remained speculative.

NuScale had to cancel the Carbon-Free Power Project in 2023 not because of design or environmental concerns, but because there were not enough customers willing to pay the high price for the electricity that would be generated. The Utah Associated Municipal Power Systems was willing to be the first customer, but as costs increased NuScale could not find enough additional buyers of what would have been a too-expensive product at $89 per megawatt-hour.

The new opportunities for small modular reactors were clear. The Tennessee Vally Authority continued to plan for building 20 small modular reactors, other utilities kept them in their long-range planning, Westinghouse continued to seek Nuclear Regulatory Commission approval of its AP300 design as various competitors pushed forward their design proposals, and the US Department of Energy anticipated that decarbonizing the grid by 2050 would require tripling the generation from nuclear power plants.

The financial challenges of bringing the new technology to market was the greatest barrier to implementation. The cost-effectiveness of building a small modular reactor made it difficult to obtain financing. Approval of new power plants using a Federally-approved design was still a business risk at the state level. Public utility commissions tasked with protecting ratepayers required assurances that a small modular reactor would produce electricity at a lower cost than alternative proposals - particularly wind and solar, with battery storage to ensure reliable supply.

The nuclear power safety director for the Union of Concerned Scientists expected more projects and companies would fail after the Carbon-Free Power Project, saying:21

small modular reactors, such as the NuScale design, will not require construction of massive containment shells or cooling towers

Source: US Department of Energy, Final Scientific / Technical Report for the Phase 1 NuScale SMR FOAK Nuclear Demonstration Readiness Project

In Virgina, small modular reactors could be constructed by Dominion Energy as an alternative to a third pressurized-water reactor at North Anna. Small reactors with six modules ("six packs") up to 12 modules ("12 packs") could be located where coal-fired power plants were closed, taking advantage of the substations and transmission infrastructure already in place.

Unless small modular reactors gain public acceptance as cost-effective sources of carbon-free electricity, it is unlikely another nuclear power plant will ever be built in Virginia. Without commitments to build more of the traditional pressurized water reactors after completion of Vogtle Unit 3 and Unit 4 in Georgia, the supply chain and skilled labor force will disappear. A former chair of the Nuclear Regulatory Commission said bluntly in 2021:22

Governor Youngkin revealed his 2022 Energy Plan in Lynchburg. He highlighted the capabilities of BWX Technologies and Framatome, and called for a "moon shot" effort to build a small modular reactor (SMR) in Southwest Virginia within 10 years as part of his all-of-the-above strategy to increase energy supplies:23

The 2023 General Assembly created a Nuclear Education Grant Fund and Program to incentivize colleges to offer a program in nuclear education, including welding classes to create workers with skills for construction and repair of the US Navy's nuclear-powered ships in Hampton Roads. A bill to create the Southwest Virginia Energy Research and Development Authority was also approved, signaling the high interest in Southwest Virginia for construction of small modular reactors at former coal mining sites.

However, the 2023 General Assembly rejected a bill setting a target to build a small modular reactor by 2032. Legislators also did not pass a proposal to authorize a revenue sharing agreement among Buchanan, Dickenson, Lee, Russell, Scott, Tazewell and Wise counties and the city of Norton. That bill would have ensured regional benefits so the windfall of taxes on a small modular reactor would not go to just one jurisdiction in which a power plant was constructed.

Southwest Virginia delegates had supported proposals to modify the Clean Economy Act, allowing power plants fueled by natural gas and coal to continue to operate past 2045. That may have generated a reaction to the revenue sharing initiative, which was modeled on an already-approved process for sharing revenue from a casino in Bristol.

Supporters of power plants using fossil fuels continued to argue that electricity generated by wind and solar facilities was unreliable, and the percentage of baseload generation after 2045 needed to be increased. Nuclear power offers reliable baseload capacity without carbon emissions, so expectations were high that a future General Assembly - as well as Appalachian Power and Dominion Energy - would support Virginia being one of the first states to build small modular reactors (SMRs).

Anticipating renewed construction of nuclear facilities, in 2023 Framatome and Central Virginia Community College expanded the Nuclear Technology Academy to train nuclear technicians. The program, started in 2004, had previously been limited to existing Framatome employees. The plan was for 30 students each year to get jobs at Framatome and earn full-time pay with benefits, while spending half their time in school.

One delegate commented after the 2023 session ended:24

Also in 2023, Framatome announced a $49 million expansion of its facilities in the Lynchburg area, with plans to hire over 500 new employees. They would be added to the 1,300 already working for Framatome in Lynchburg and Campbell County. Of the 500+ new hires, average salaries were expected to be $120,000/year. Of the new hires, 80% were expected to be engineers.

The expansion included building a new technical training center for employees to service small modular nuclear reactors. Framatome chose not to design its own small modular reactor, but instead to provide technical services supporting all designs that ended up getting approved.25

nuclear reactors run at maximum power more than other sources of generating electricity

Source: US Department of Energy, What is Generation Capacity?

Dominion Power could install a small modular reactor at the North Anna or Surry nuclear power plants. In 2023, a data center developer proposed to build 30 data centers next to the Surry Nuclear Power Station, and to construct four-six small modular reactors and/or hydrogen-fueled power plant at the "Surry Green Energy Center."

The US Department of Energy identified that 80% of sites of former coal-fired power plants were suitable for small modular reactors. Those sites were desirable because electricity transmission lines were already in place and sites were zoned for industrial use.

In a 2022 report, the Federal agency examined the location of 157 retired coal-fired power plants and 237 operating sites. Only one in Virginia was judged to be suitable for small modular reactors, though a second facility was a potential site despite two "flags" in the assessment.

Criteria for suitability included distance from an existing population center, seismic risk, topography, and proximity to military bases. The Clover plant in Halifax County may have been the suitable site identified by the US Department of Energy, in part because of its proximity to a large reservoir offering cooling water.

The demand for electricity in Northern Virginia to power data centers triggered discussion in 2023 of building small modular reactors in Loudoun County. Each module of a small modular reactor could provide up to 300 megawatts, equal to what each new data center might require.

The Dominion Energy official responsible for acquiring power generation stated that nuclear generation was essential to decarbonize the grid. He suggested population-dense Loudoun County was an unlikely location for the first generation of the new reactors, but in the future they might be constructed near major power users and population centers. Referencing the safety record of reactors in the US Navy's nuclear-powered vessels, he suggested the public would eventually support small modular reactors in part because:26

small modular reactors could be constructed in populated areas close to facilities that create high demand, such as data centers

Source: International Atomic Energy Agency, Accelerating SMR Deployment: New IAEA Initiative on Regulatory and Industrial Harmonization

In contrast, construction of new solar facilities was delayed by the slow pace at which the grid operator, PJM, was completing the interconnection studies required to avoid overloading transmission lines. In April 2022, PJM had a backlog of 1,200 projects. The speed at which the grid would be decarbonized was affected by the inability of clean energy projects to deliver electricity.27

The Virginia Growth and Opportunity Board ("GO Virginia") awarded a grant in 2023 to the LENOWISCO Planning District to fund a study of potential locations for small modular reactors in Southwest Virginia. The feasibility study quickly identified seven possible sites, as reported by Cardinal News:28

- Bullitt Mine complex in Wise County

- Limestone Mine, Scott County

- Lee County abandoned mined land site near the Wise County border

- Mineral Gap-Lonesome Pine Park in Wise County

- Project Intersection in Norton

- Red Onion in Dickenson County

- Virginia City Hybrid Energy Center in Wise County

Southwest Virginia also partnered with Lynchburg in 2023 in hopes of becoming one of 20 TechHubs designated by the US Economic Development Administration. The Federal agency was advancing industrial policy, directing government funding to selected locations where private companies could establish American dominance in critical technologies such as advanced manufacturing.

The Lynchburg Regional Nuclear Industrial Technology Commercialization Hub (NITCH) proposal was supported by the local nuclear companies, BWX Technologies and Framatome. The consortium also coordinated with InvestSWVA, reflecting the political pressure to use the prospect of a small modular reactor to improve the economy in Southwest Virginia.29

Guided by the academic and industry stakeholders in the Virginia Nuclear Energy Consortium, which the General Assembly had created in 2013, the Southwest Viginia consortium submitted Virginia's Technology Workforce and Innovation in Nuclear Hub (TWIN) proposal. Like the Lynchburg Regional Business Alliance consortium, it prioritized workforce development. The "tech hub" differed by also highlighting the value of building small modular reactors, especially to power data centers. The Lynchburg consortium dropped plans to become a tech hub and sought just a strategy planning grant to enhance nuclear manufacturing.

The two applications ended up being complementary rather than competitive. Criteria including prioritizing Federal investment in low-income areas, so Southwest Virginia had a better opportunity for winning tech hub designation. BWXT supported both proposals and planned to join both consortia, if the US Economic Development Administration approved funding for both applications.

In 2025, the Virginia Department of Energy funded the establishment of a partnership named the Virginia Innovative Nuclear Hub (VIN Hub). It included representatives from the nuclear industry, universities, and the Virginia Nuclear Energy Consortium Authority created by the General Assembly in 2013. The goal was to create the Virginia Research and Education Reactor Facility, a micro-scale reactor where partners in a collaborative model could combine efforts to research, test, and train.30

By 2024, Governor Youngkin had revised his proposal to build a small modular reactor first in Southwest Virginia, on some of the 100,000 acres of former coal mine land. He still supported adding such electricity generation facilities to the region, but concluded that other sites that already had transmission lines installed were more suitable and more likely to get a Nuclear Regulatory Commission license first.

The governor said at a March 19, 2024 meeting at the Southwest Virginia Higher Education Center in Abingdon:31

In 2024, the US Navy identified seven sites where it would study building shore-based nuclear power. Three were in Maryland and North Carolina, and four were in Virginia:32

- Naval Air Station Oceana

- Naval Support Activity South Potomac (Dahlgren)

- Naval Weapons Station Yorktown

- Marine Corps Base Quantico

there will be little electricity provided by nuclear power plants by 2050 unless licenses are renewed for existing nuclear power plants or new ones are constructed

Source: US Department of Energy, National Offshore Wind Strategy (2016) (Figure 2-6)

the Department of Energy sees great potential in small micro-reactors

Source: U.S. Energy Information Administration, State Nuclear Profiles 2010