the generators burning methane to produce electricity at the Prince William County landfill are housed in a simple industrial building

the generators burning methane to produce electricity at the Prince William County landfill are housed in a simple industrial building

Landfills are rich in organic material, thanks to the garbage discarded from households and the yard waste tossed into the garbage. Grass clippings, residue in pizza boxes, and the contributions of cats to litter boxes all end up being buried in solid waste landfills. Food waste tossed into the garbage generates nearly 60% of fugitive methane emissions from municipal solid waste landfills

Today, landfills are carefully designed in cells, with geotextile fabrics and impervious liners to contain the material deposited by trash trucks. A solid clay cap on top of a closed landfill cell will keep rainwater out, and liners underneath will keep groundwater out, but decay of the waste will generate garbage juices ("leachate) within the cell. Modern cells can contain such liquids indefinitely.

Bacteria inside the cell will also generate gases through decomposition of organic material. In addition, discarded materials may vaporize and chemical reactions within a landfill may generate gases. While landfill gases are roughly 50% methane and 50% carbon dioxide, other minor components can have significant impacts. Old landfills, without impervious caps, may literally stink up a neighborhood with sulfides, ammonia, and volatile organic compounds.

Landfills that accept construction and demolition debris will have gypsum wallboard. The sulfur in the calcium sulphate (CaSO4) can result in a "rotten egg" smell.1

Decomposing organic material generates so much carbon dioxide and methane gas that the pressure must be released before a landfill's clay cap fractures and "pops." When solid waste is placed within a modern landfill's cell, a framework of porous plastic pipes is laid down at different levels as the pile grows. When the final clay cap seals off a cell, the gas collection pipes are connected to vents installed through the clay cap. As organic material decomposes, gas builds up within the cell, then migrates to the porous pipes and is vented safely to the outside.

terraces and drainage ditches minimize erosion on the top of clay caps, while gas collection systems prevent pressure generated within the cell from creating cracks in the clay caps

Culpeper County officials installed a gas extraction system after closing their landfill, because excessive levels of methane were escaping. Pumps sucked out the gas from pipes inserted into the landfill, at a rate that did not lower the pressure within the landfill enough for oxygen to infiltrate and trigger a fire.

Culpeper had to increase the number of extraction points in 2018, because methane levels were still too high after major rainstorms. As one county official described the problem:2

Burning the methane extracted from landfills ensures it does not accumulate and form an explosion risk. In addition, methane is a greenhouse gas with greater impact on global warming that carbon dioxide. Burning methane converts the CH4 to CO2.

Methane is also a potential energy source, though the gas generated at landfills has roughly half the energy value of natural gas extracted from underground wells. Large landfills can install small microturbines or fuel cells to burn the methane and generate electricity, in a process that can also minimize odors and reduce global warming. Revenue from sale of the electricity can be used to offset a portion of landfill operating costs.3

methane extracted from decomposing organic material in a landfill is burned to reduce explosion risks and to minimize the impact on global warming

The regional landfill in Suffolk, operated by the Southeastern Public Service Authority (SPSA), developed a system to utilize landfill gas in the 1990's. Methane was collected at the landfill, then piped 2.3 miles to the Ciba Specialty Chemicals plant (later purchased by BASF) to be burned in the facility's boilers. Starting in 2011, landfill gas was also used to generate electricity sold to the local utility, further reducing pressure at the clay cap and ensuring compliance with Clean Air Act regulations.

In 2023, the Southeastern Public Service Authority opened a $25 million renewable natural gas facility at the Regional Landfill in Suffolk. Methane was injected into the nearby TC Energy pipeline rather than burned onsite to generate electricity. A spokesperson for the Southeastern Public Service Authority said changing the way landfill gas was used enabled the authority to:4

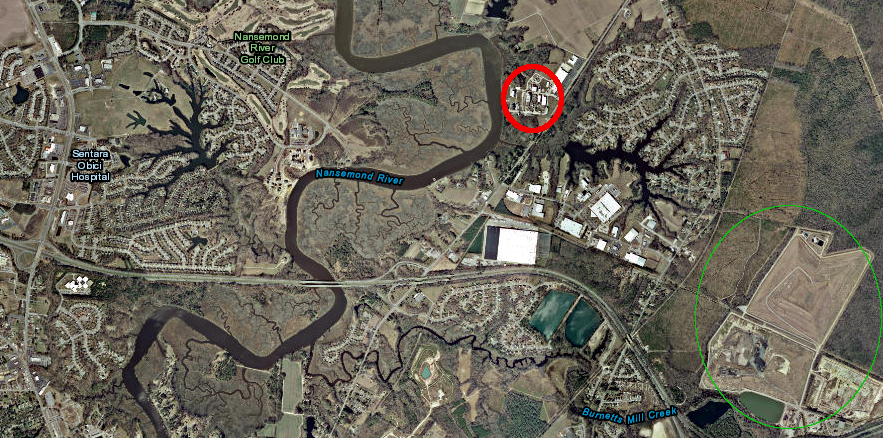

the South Hampton Roads regional landfill (green circle) once piped methane to the BASF (formerly Ciba) chemical plant on the Nansemond River (red circle)

Source: ESRI, ArcGIS Online

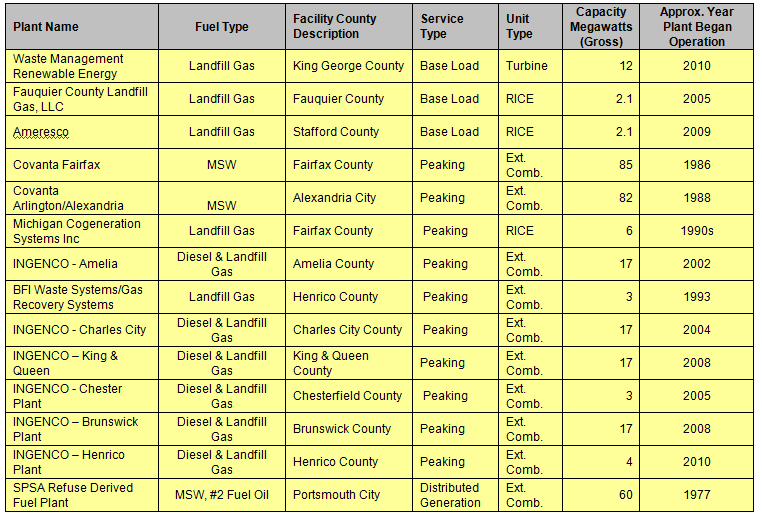

Municipal solid waste can also be compressed into Refuse Derived Fuel (RDF) pellets and burned to heat water into steam, which spins turbines to generate electricity. Only large landfills generating sufficient methane can justify the investment required to generate electricity. As of 2013, the Virginia Department of Environmental Quality (DEQ) identified 14 electric generating plants using municipal solid waste and landfill gas as a fuel, all located near the urban areas of Northern Virginia, Richmond, or Hampton Roads.5

Fauquier County has been the most ambitious of the small projects, creating a $3 million, 2-megawatt (MW) merchant power plant in 2004 without grants, subsidies, or tax credits as a precursor to a planned biorefinery, intended to help the community achieve energy independence. The American Recovery and Reinvestment Act (ARRA) then provided over $825,000 to expand the Corral Farm Landfill project.6

electric generating plants using municipal solid waste (MSW) or landfill gas for fuel

Source: Virginia Department of Environmental Quality (DEQ), Electric Generating Plants Currently Operating in Virginia (as of March 25, 2013)

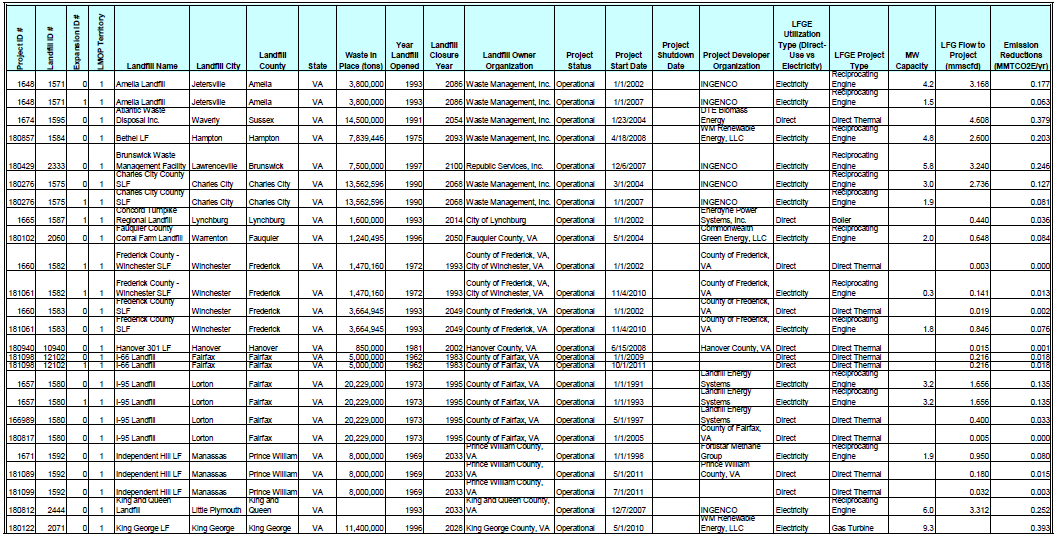

Smaller projects can utilize landfill gas for a variety of purposes, including evaporation of leachate to reduce its volume. The Environmental Protection Agency (EPA) list of electricity-generating sites is broader than the Virginia Department of Environmental Quality list. EPA has identified 30 projects in Virginia using landfill gas at one time or another, including the projects generating electricity from landfill methane.

In Hanover County, a closed landfill generated only a low flow of gas, but it was sufficient for a burner system water-based paint into a dry powder for deposit in the new landfill. EPA also noted that the Frederick County/City of Winchester project to generate electricity at the landfill, triggered in part by community concerns about the development of new power transmission lines bring electricity from distant plants, would recover the public investment in 5-9 years.7

Landfill Gas Energy Projects identified by EPA, including direct utilization of gas as well as generation of electricity

Source: Environmental Protection Agency (EPA), Energy Projects and Candidate Landfills

In Prince William County, 100 wells within closed cells at the landfill collect methane. Some was burned to generate electricity and heat the Fleet Maintenance Building, and some was used as fuel for the nearby animal shelter. Animals not adopted within the shelter's timeframe are euthanized, and methane from the landfill offsets propane used in the incinerator to dispose of carcasses.

no money was wasted on esthetics when constructing the original metal structure housing the electrical generator and the flare gas stack at the Prince William County landfill

Source: Prince William County, Landfills as Renewable Energy Sources

In 2023 the county planned to expand the use of landfill gas. Opal Fuels proposed to concentrate the methane in the landfill gas, converting it to renewable natural gas (RNG), and transport it to a nearby pipeline for distribution. The project would eliminate most flaring of excess gas on-site. That would reduce greenhouse gas emissions from the landfill by 90% and increase efficiency of the use of the landfill gas by 60%.

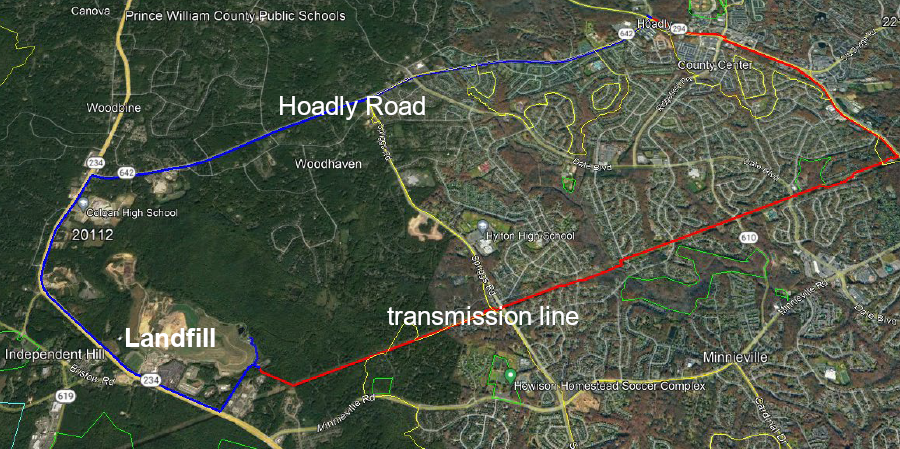

Plans to construct a new 8-inch diameter pipeline to connect the landfill with the existing natural gas pipeline network caught neighbors by surprise. Though much of the proposed pipeline route paralleled an existing electricity transmission line, rights-of-way had to be acquired in order to cross private land. An alternative route was identified as well, using a public road instead.8

two pipeline routes were proposed to transport renewable natural gas (RNG) from the Prince William County landfill to the existing pipeline network

Source: Prince William County, Renewable Natural Gas Project at County Landfill

Landfill gas operations are economical only if there is a customer willing to purchase the gas, or electricity generated by the gas. The company running a gas extraction network at the Concord Turnpike Landfill in Lynchburg decided in 2019 to stop operating, after its only customer stopped purchasing the gas. The Region 2000 Services Authority needed the gas removed, to minimize the risk of pressure building up and cracking the clay cap of the landfill. That authority considered it economical to assume responsibility, since the gas was 60% methane and there was expected to be a 30-year supply.

The Region 2000 Services Authority was already operating a landfill gas collection system at the Campbell County landfill. That system was installed in 2016, after complaints by neighbors about odor had peaked.9

At the Charles City Landfill, Waste Management partnered with Ingenco to convert landfill gas into electricity. Ingenco converted over 30 old diesel engines that once powered tractor trailer trucks to burn landfill gas rather than diesel fuel. The engines power generators, and approximately 70,000 megawatt hours (MWhs) of electricity from the "gensets" is sold through the Eastern Interconnection grid operated by PJM Interconnection.10

The Roanoke Valley Resource Authority added a methane collection system at the Smith Gap Landfill in Roanoke County in 2025. The landfill collected 700 million pounds each year of municipal solid waste, and decomposition of the fresh organic material required burning off the methane in order to maintain the clay cap. A private company funded installation of methane capture and processing facilities, anticipating to capture at least 1,000 cubic feet per minute. The landfill projected it would start receiving over $800,000/year in royalties for renewable natural gas, with the potential for doubling the revenue if the system captured 2,000 cubic feet per minute.

The chief executive officer of the Roanoke Valley Resource Authority told the Roanoke City Council in April, 2025:11