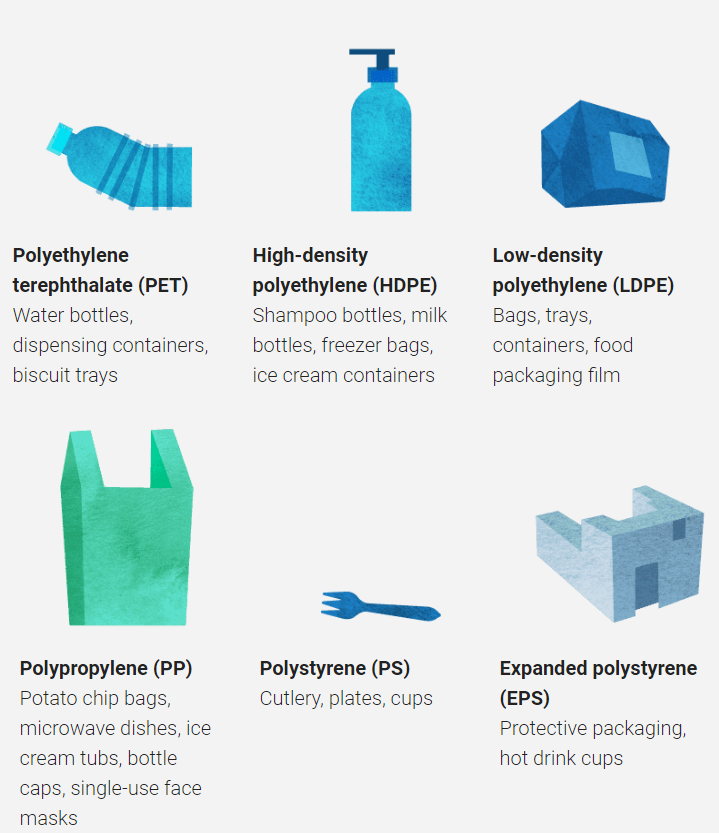

different types of plastic, with different chemistry, complicate efforts to recycle

Source: United Nations Environment Programme, Our planet is choking on plastic

different types of plastic, with different chemistry, complicate efforts to recycle

Source: United Nations Environment Programme, Our planet is choking on plastic

The chemistry of plastic polymers is complex and the cost of producing commonplace items such as plastic grocery bags is low, making recycling especially challenging. It is cheap to manufacture a new item witb plastic designed to have specific qualities. It is expensive to collect bulky used plastic items, and to separate the different components for reuse.

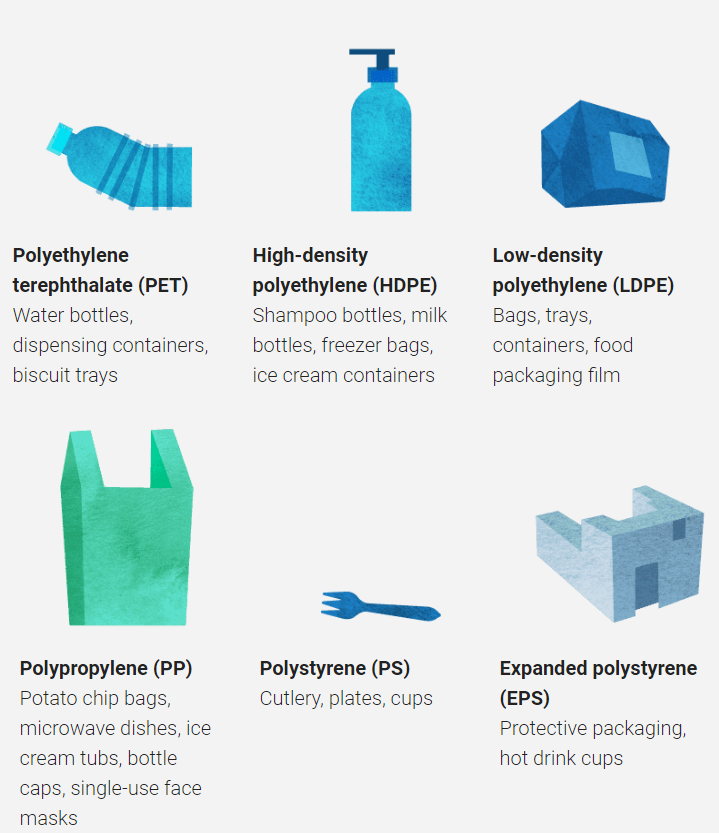

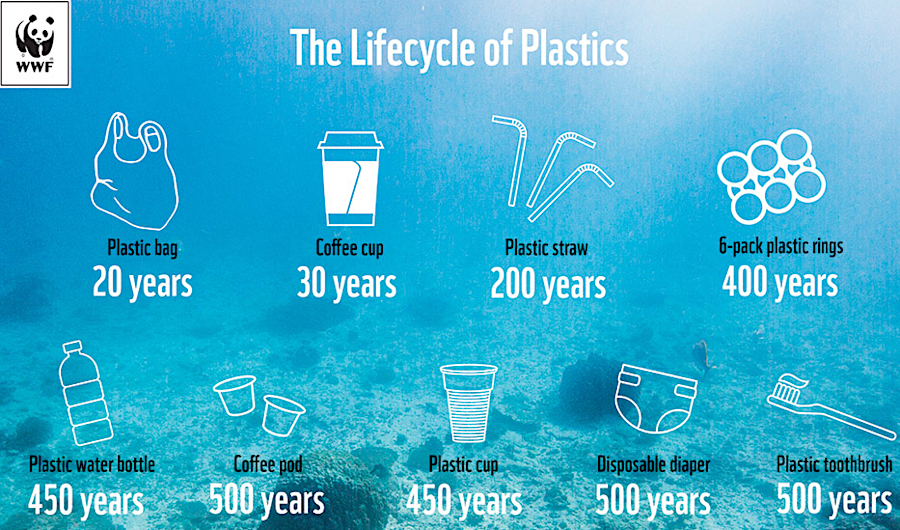

Microplastics smaller than five millimeters and nanoplastics smaller than one millimeter are shed as clothing goes through cycles in washing machines, and as discarded plastic bottles are washed down stream channels. Many plastics are not biodegradable. They are so resistant to sunlight, bacteria, and physical abrasion that they may persist almost in perpetuity, but in just smaller and smaller particles. Thousands of years from now, researchers may be able to date layers of archeological deposits based on the time periods when different plastics were manufactured.

Additives are incorporated into different plastics, such as fabrics with phosphate-based and brominated-based flame retardants and stain resistant chemicals. The additives leach out of the microplastic particles relatively fast, since travel time to migrate from small particles to the surface is faster.

The toxicological effects of the additives is unclear. Ingesting plastics such as polyethylene may be harmful to oysters and humans, but the most significant impacts may be due to the cocktail of different additives in the plastic rather than to the polyethylene molecules themselves. "Plastic" itself may trigger biochemical reactions, but greater risks may come from what extra molecules were incorporated into a plastic item during production. In addition, microplastics may magnify the ability of virus particles and other pathogens to interact with cells.

viruses and microplastics might interact to have a greater impact than either one individually

Source: Trends in Microbiology, Oceanic Hitchhikers – Assessing Pathogen Risks from Marine Microplastic

Because plastics are now pervasive in the environment, cumulative exposure time could determine if plastic waste particles are a problem for living organisms. Oysters in the ocean may accumulate microplastic particles that marginally affect the ability to feed, but the oyster naturally dies before other impacts are noticed. Mussels that live 50-70 years may be at greater risk, because "the dose makes the poison."

The mechanism of exposure may shape the significance. Humans are exposed to microplastic particles in dust around the house, created by friction when sitting on stain-resistant chairs and by flapping a sheet with polyester fibers before making the bed. Many cosmetics applied as eyeliner or facial creams contain microplastics. Particles ingested into the lungs may interact with a human body differently than particles from food packaging that end up being swallowed at a meal. Eliminating processed food from a diet may reduce the risk of disease less than eliminating modern fabrics from furniture and clothing, or eliminating cosmetic makeup from a daily routine.

Plant and animal cells have not evolved in the past to deal with the new chemical compounds developed over the last century. Because the process for determining health impacts occurs after new plastic formulas move into widespread production and exposure, forms of life born after World War II have become "guinea pigs" to test whether plastic compounds are safe - and, if not, what is the maximum contaminant level that regulators should establish.

The rate of plastic production has grown faster than that of any other material since the 1970's. The tiny plastic fibers in cigarette butts are the most common plastic waste in the environment, with plastic waste used for food items (bottles and caps, grocery bags, food wrappers, etc.) the second-most common.

Waste discarded on the ground or into wastewater systems ends up washing into rivers. Along the Mississippi River, almost 75% of the litter is plastic. The polymer chains with strong carbon-carbon bond increase durability and resistance to degradation, and with the addition of chemical additives plastics were not designed for recycling.

Even bioplastics made from fungi, sugar cane, corn and other plant materials may not be compostable, unlike materials made from wood fiber. Most plastic ultimately ends up as microplastic particles in the ocean - and in human bodies across the world.

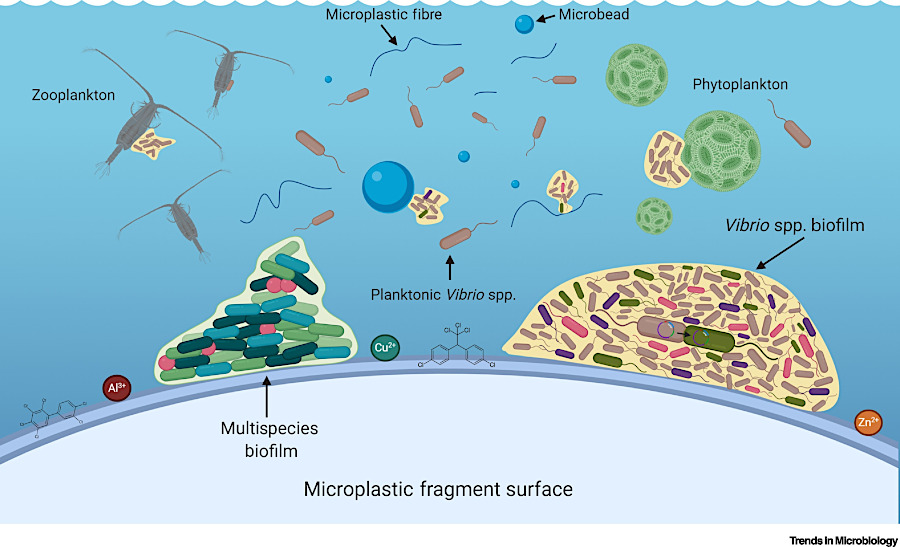

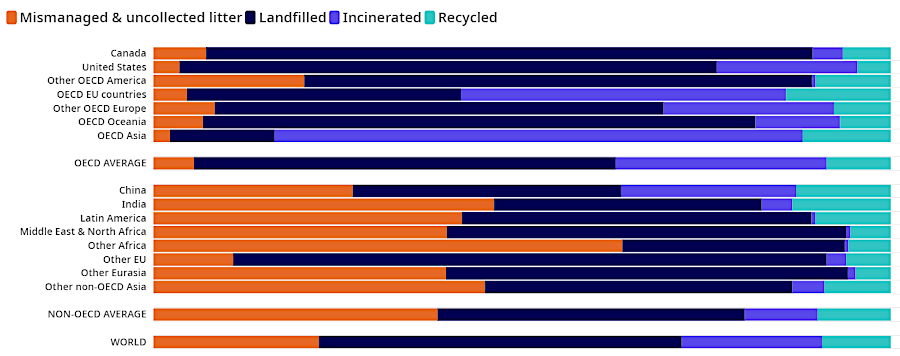

Statistics vary according to country and organization generating the data, but the percentage of recycled plastic is only about 10% worldwide. The United Nations Environmental Programme reports:1

less than 10% of the plastic captured in the waste stream is recycled into new material of some sort

Source: Government Accountability Office (GAO), Science & Tech Spotlight: Advanced Plastic Recycling (GAO-21-105317)

The problem is increasing; global plastic waste is predicted to almost triple by 2060. The National Academy of Sciences estimated that the amount of plastic reaching the ocean is equivalent to dumping a garbage truck into the ocean every minute. By 2030, the amount of plastic reaching the ocean each year would be equivalent to half of the total weight of fish caught each year.2

In Hampton Road and Richmond, Chesapeake Materials Services purchases plastic waste and recycles it. In the City of Winchester, Trex is a major recycler of plastic. It converts stretchy plastic materials and sawdust into composite decking and railing that offers superior durability to pressure treated wood. The company advertises:3

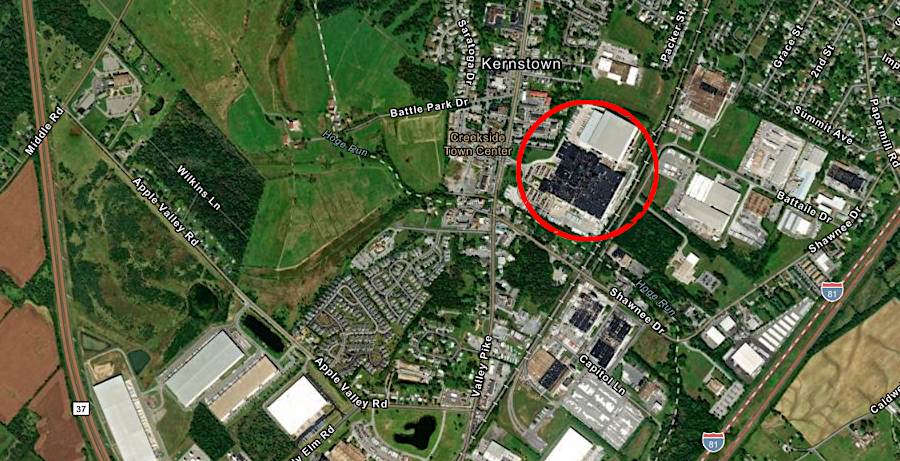

Trex has its headquarters and a major manufacturing plant (red circle) in Winchester

Source: ESRI, ArcGIS Online

The business model for plastic recycling in the United States was, until 2017, based upon shipping the material to China for sorting, grinding, cleaning, melting and remolding. However, China changed its policy in 2017 and stopped accepting most recyclable materials.

That decision forced existing businesses collecting waste to change how they separated and sold recyclable products. Not all recycling businesses could adjust successfully.

For example, the scale of operations at Container Rentals and Recycling outside of Charlottesville was too small to provide adequate revenue for upgrading the equipment, or for storing recycled product until finding new customers to purchase plastics, paper, glass and metals. The company dropped out of the recycling business in 2018, and stopped accepting waste other than construction and demolition debris (CDD).4

competition for processing recyclables in Charlottesville ended when Container Rentals and Recycling dropped out of the business in 2018

Source: ESRI, ArcGIS Online

While the market for #1 plastic (polyethylene terephthalate, PET or PETE) and #2 plastic (high density polyethylene or HDPE) remained viable, municipalities stopped trying to recycle #3 (polyvinyl chloride or PVC), #4 (low-density polyethylene), #5 (polypropylene), #6 (polystyrene) and other forms.

Without a market for that plastic waste, in the short run more of it had to be incinerated or landfilled. China's decision triggered development of proposals to recycle plastics in a new manner, in "advanced recycling" facilities.

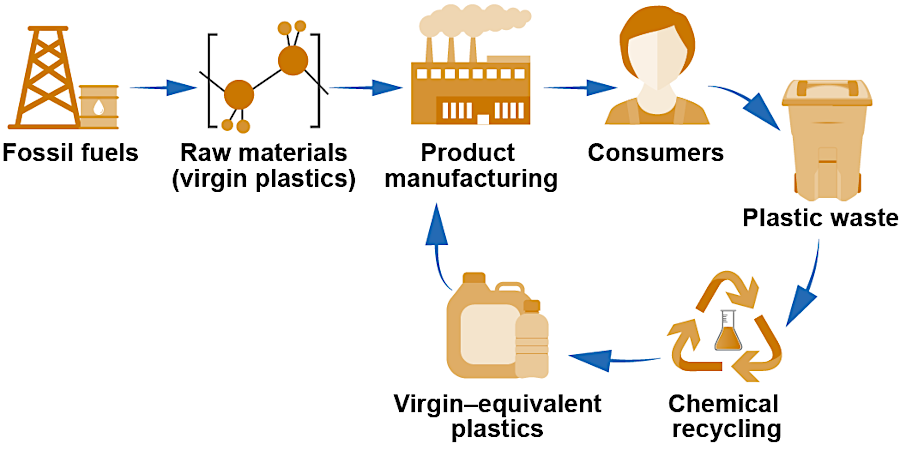

Advanced recycling processes plastics used heat and chemical processes, rather than physical shredding, to convert polymers to monomers which served as "feedstock" materials for new plastic production. Plastic waste is chopped into small material, then heated to 800-1,500° Fahrenheit. At that temperature, and with the help of catalysts, the carbon-carbon bonds break. Some material forms a char which is discarded as a non-hazardous waste, while most ends up as a pyrolysis oil which is fed into a small-scale refinery.

The oil is vaporized by heat in a low-oxygen environment to create different gases. The pyrolysis products are separated in the refinery into liquid oil, gases (methane, ethane, butane and propane) and solid char. About 15-20% of the oil and gases are then converted back into propylene and ethylene for manufacturing new plastic products. The remainder becomes diesel fuel.

At least in theory, advanced recycling can also convert plastic waste into jet fuel. Pyrolysis and gasification to create fuel does not qualify as a "closed loop" recycling technique, since the end product is burned for energy and is not converted into another form of plastic.

Another process uses both chemical and biological action to convert plastics with tough polymer chains into smaller molecules. That technique, still in the research stage, uses an initial chemical process to degrade the large polymers into a form which can be digested by the bacterium Pseudomonas putida. Different types of plastic are converted to re-useable molecules at different temperatures, so scaling the process to be cost-effective in a commercial setting is still in the future.

advanced recycling creates feedstock for producing new plastic items

Source: Government Accountability Office (GAO), Science & Tech Spotlight: Advanced Plastic Recycling (GAO-21-105317)

Critics question how much of the plastic is actually recycled into a useful products rather than simply incinerated, potentially releasing dioxin and endocrine disruptors from the plastic into the atmosphere. Opponents of an advanced recycling plant proposed in Indiana claimed less than 20% of the plastic was actually recycled.5

Braven Environmental and Governor Northam announced plans in 2020 to open the first advanced recycling plant in Virginia in Cumberland County. Hauling recyclables is a major expense, and affects the feasibility of locating new advanced recycling facilities. Assuming each advanced recycling facility would draw from a 150-mile supply radius, Virginia might end up with six advanced recycling plants.6

In 2021, the General Assembly designated "advanced recycling" facilities as manufacturing rather than as waste management facilities. That designation exempted them from requirements in the state's Solid Waste Management Act that regulated landfills, incinerators, and waste transfer stations.

Opponents objected to the bill proposed by Del. Ken Plum, generating this rejoinder from an advocate of advanced recycling:7

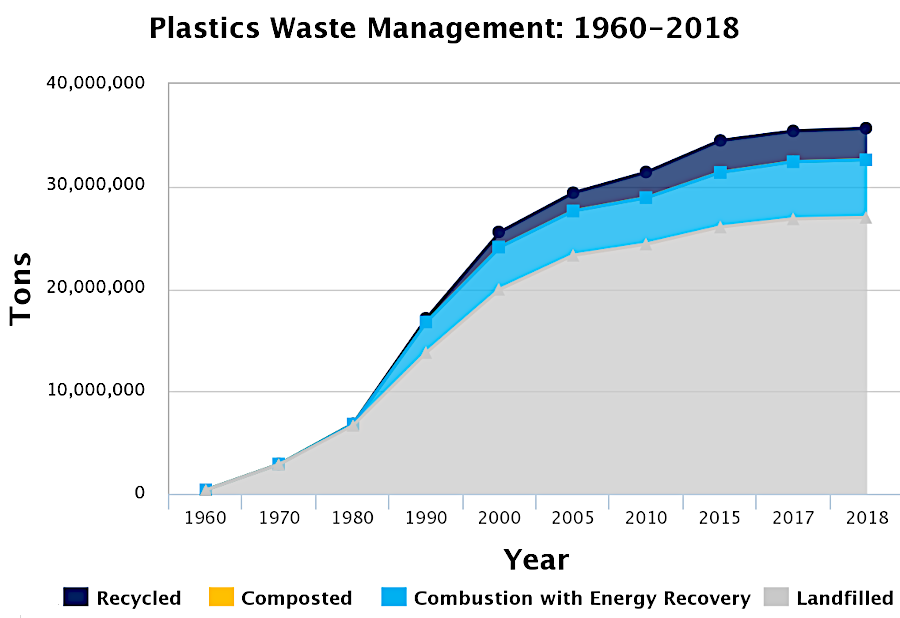

The Environmental Protection Agency had calculated in 2018 that less than 10% of plastic waste was being recycled. The material being recycled depended upon the number stamped on the plastic. Almost 30% of polyethylene terephthalate (PET) and High-Density Polyethylene (HPDE) plastic, used for bottles and other items labelled #1 and #2, were recycled.8

most plastic that gets into the waste stream is landfilled, while plastic that never gets into a trash container ends up in the oceans

Source: Environmental Protection Agency (EPA), Plastics: Material-Specific Data

In Virginia, 1.3 million tons of plastic waste were being buried in landfills. Advanced recycling advocates projected the new plants could push total plastics recycling to 65%, capturing the #3 (polyvinyl chloride or PVC), #4 (low-density polyethylene), #5 (polypropylene), and #6 (polystyrene) items. Being able to dump all plastics into a common recycling bin also might capture the high percentage of #1 plastic (polyethylene terephthalate, PET or PETE) and #2 plastic (high density polyethylene or HDPE) items that go into landfills or oceans.

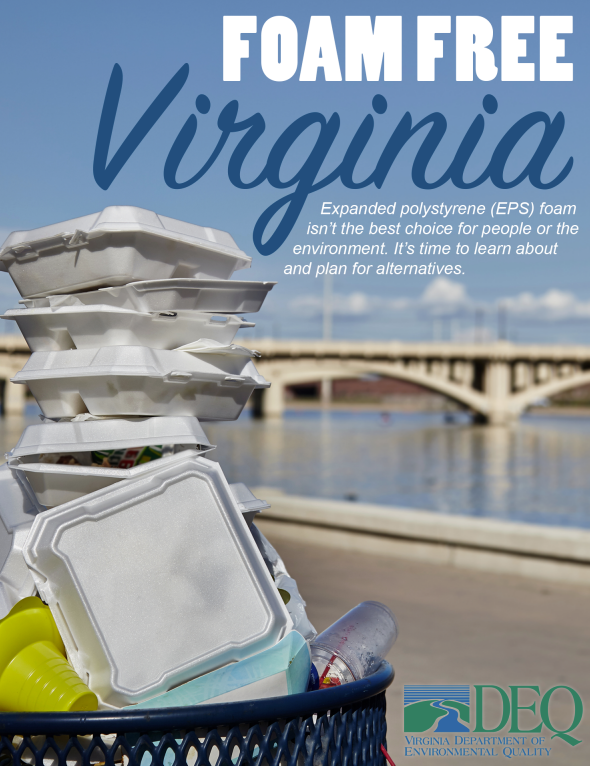

Source: American Chemistry Council, Cooking with Blair - Recycling Facts

The reclassification of advanced recycling facilities managed to get through the General Assembly in 2021 after it was linked to a separate bill limiting the use of expanded polystyrene (Styrofoam) containers for take-out food. The "Great Polystyrene Compromise of 2021" banned major restaurant chains from using non-biodegradable plastic foam by 2023. After later compromises, the ban on use by food vendors with 20 or more locations in Virginia went into effect on July 1, 2025. All schools and food vendors had to stop using Styrofoam and other single-use expanded polystyrene products by July 1, 2026.

To set an example, Governor Northam issued Executive Order 77 ending purchase of single-use plastics by all state agencies and higher education institutions in 2021. State facilities could no longer use expanded polystyrene food service containers, plastic straws, plastic knives/forks/spoons, or single-use plastic water bottles, unless needed for medical, public health, or public safety use. Exemptions were allowed, and the next governor had the option of revising Northam's order, but he directed that appropriate alternative replacement items be implemented for all state agency uses by the end of 2025. Governor Youngkin later changed that order.

the ban on single use expanded polystyrene products (Styrofoam) for food use began to go into effect on JUly 1, 2025

Source: Virginia Department of Environmental Quality (DEQ), Foam-Free Virginia Fact Sheets

Opponents of the polystyrene ban highlighted the economic impacts on small vendors. The Virginia Manufacturers Association stated that environmentally sustainable alternatives were not available for all items and few jurisdictions had facilities for composting the alternatives. The organization claimed that Executive Order 77 would replace 14.4 million metric tons of plastic packaging with 64 million tons of other material that would end up in landfills.

Some also objected because the reduction of polystyrene use would reduce the flow of one-use plastic material to advanced recycling facilities. The sponsor in the General Assembly for the ban on polystyrene responded:9

recyclable #1 and #2 plastics from Charlottesville were being hauled to North Carolina for processing in 2020, when plans were announced for an advanced recycling plant in Cumberland County

Source: Rivanna Solid Waste Authority, Recycling Update - February 2020

China was not accepting plastic waste and industry forecasters predicted plastic production would double by 2040, but the commercial viability of advanced recycling facilities was questionable. By 2021 the American Chemistry Council had successfully lobbied the Virginia General Assembly and 13 other state legislatures to classify advanced recycling facilities as manufacturing sites, exempting them from landfill and waste management regulations.

Creating the opportunity to reuse plastic was designed in part to block states from establishing a tax on plastic bags and other "polluter-pays" measure. Focusing on recycling rather than waste avoidance was one reason the Virginia Conservation Network objected to the Great Polystyrene Compromise of 2021. Some opponents described advanced recycling as just "greenwashing" to:10

In 2021 the technology for converting waste plastic into diesel/jet fuel and clean plastic resin was still immature; costs remained higher than profits. The technology was based on heating the waste in a closed container that blocked oxygen, causing the plastic molecules to melt and separate without bursting into flame.

The US Department of Energy successfully demonstrated in 2022 how pyrolysis could be used to recover the fibers and polymers in wind turbine blades, recycling what otherwise would go into a landfill. A company chose to develop a commercial facility near Knoxville, Tennessee, to recycle 5,000–7,000 fiberglass wind turbine blades annually.11

Transport of unsorted plastics to an advanced recycling facility, followed by controlled pyrolysis with little or no oxygen, appeared to produce more greenhouse gases than the alternatives of standard incineration or landfilling. In addition, pyrolysis created dioxins and other toxic gases.

The quality of the plastics being recycled was part of the problem. Garbage collectors had no way to limit associated food waste and other contaminants placed in the recycling bins before pickup, limiting the quality of the desired end products. Efforts to reproduce waste-to-fuel operations in a laboratory with full-scale facilities capable of handling the wastes of hundreds of thousands of people led to business failures and decisions in other states, such as Idaho, to abandon advanced recycling at least temporarily.12

Virginia was the 10th state to approved advanced recycling, but in 2020 the General Assembly also authorized local jurisdictions to impose a $0.05 tax on disposable plastic bags. The City of Roanoke was the first to approve a bag tax. The goal was not to raise money, but to alter the behavior of shoppers. A city official noted that the bag tax was:13

In early 2022, Braven Environmental cancelled its plans to build an advanced recycling facility in Cumberland County, without explanation. In September, a different company announced plans for a $1.1 billion chemical recycling plant near Harrisburg in Pennsylvania to turn waste plastic into naphtha and then new plastic. The facility would have the capacity to recycle 450,000 tons of plastic waste annually from Pittsburgh, New York and Philadelphia, but was not targeting the Virginia market.14

In April, Governor Youngkin issued an Executive Order that tasked the Department of Environmental Quality (DEQ) to identify how Virginia could attract opportunities for attracting post-consumer recycled product business entities to the state:15

At the same time, Governor Youngkin dropped the requirement established earlier by Governor Northam that state agencies phase out single-use plastics by the end of 2025 and asked the the General Assembly to reconsider its mandate to end the use of plastic foam containers made from expanded polystyrene. His retreat from banning plastic containers may have been affected by lobbying from the natural gas industry. If plastic containers were banned, then there would be reduced use of natural gas as a feedstock for production of plastic.16

In his 2022 budget, Governor Youngkin proposed that the legislature postpone its ban on use of polystyrene for food containers for five more years. The deadline for restaurants with 20 or more locations would be pushed back from 2023 to 2028, and the 2025 deadline for all restaurants would be pushed back from 2025 to 2030. He was not successful in delayng the ban.

The 2021 General Assembly had reached a compromise on authorizing advanced recycling facilities by also agreeing on the deadlines for banning polystyrene. The 2022 proposed change caused on negotiator to say:167

by design, the molecules that create plastic items degrade very slowly

Source: World Wildlife Federation, The lifecycle of plastics

worldwide, only 9% of plastic is recycled

Source: Organisation for Economic Co-operation and Development (OECD), Plastic pollution is growing relentlessly as waste management and recycling fall short, says OECD