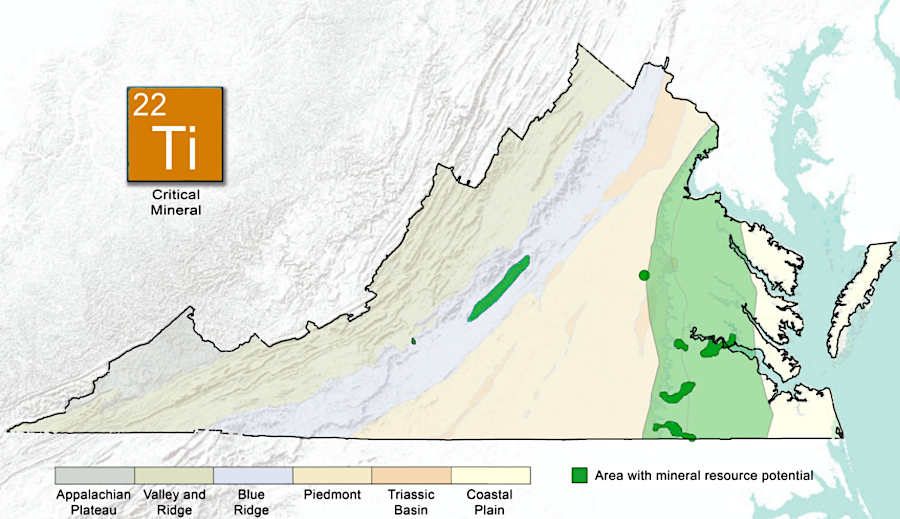

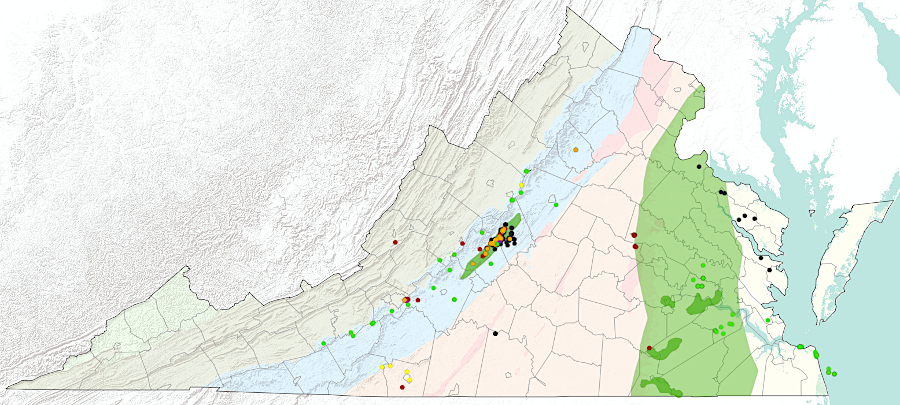

titanium has eroded from the Blue Ridge, including the Tye River region, and accumulated in Coastal Plain sediments (yellow)

Source: US Geological Survey (USGS), Heavy-Mineral Sand Resources in the Southeastern U.S.

titanium has eroded from the Blue Ridge, including the Tye River region, and accumulated in Coastal Plain sediments (yellow)

Source: US Geological Survey (USGS), Heavy-Mineral Sand Resources in the Southeastern U.S.

Titanium is present throughout the Blue Ridge metamorphic rocks. Crystals of blue quartz, which have an unusual waxy luster and incorporate the titanium-containing mineral rutile, have been found from Loudoun to Grayson counties.1

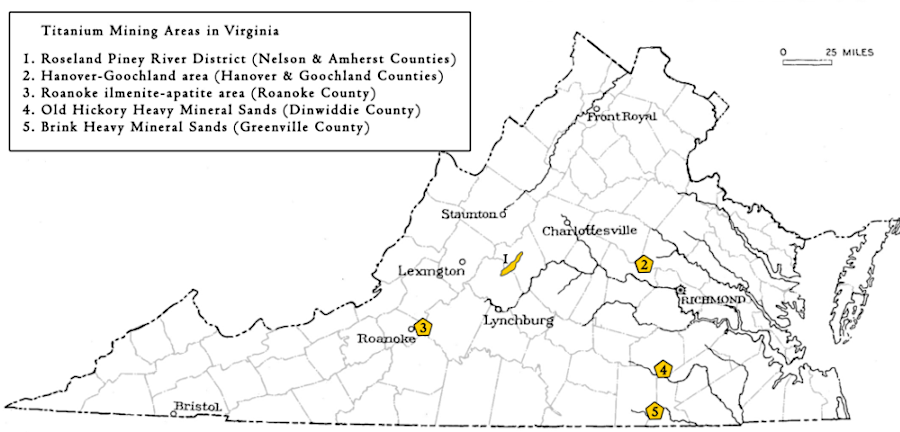

Commercially-valuable deposits of titanium have been found in the Blue Ridge on the Piney River in Nelson County and in Hanover County. Sedimentary deposits of titanium which eroded from the source rock in the Blue Ridge have been found near Emporia, in the Old Hickory Heavy Mineral Sand Deposit.

Within the United States, titanium is mined in just Virginia, Nevada and Utah. In Virginia, in addition to the Roseland-Piney River district, titanium ore has been mined from Montpelier metanorthosite (a metamorphosed rock that was once molten magma) in the Goochland terrane in the Piedmont physiographic province, and from sediments on the Coastal Plain.

The Piedmont deposits in Hanover and Goochland counties were in thick saprolite. It had formed from the decay of underlying granitic biotite gneiss where the bedrock was cut by pegmatite dikes rich in rutile and ilmenite, which are oxides of titanium. Titanium, like quartz, dissolves very slowly in water. Crystals of other minerals such as feldspar transform into clay particles and wash away, concentrating the titanium that is less mobile.

Mining titanium in the Piedmont started in 1957. Since 1993, the operation has focused on producing feldspar and silica products.2

titanium has been mined in the Blue Ridge, Piedmont, and Coastal Plain

Source: Virginia Department of Energy, Titanium

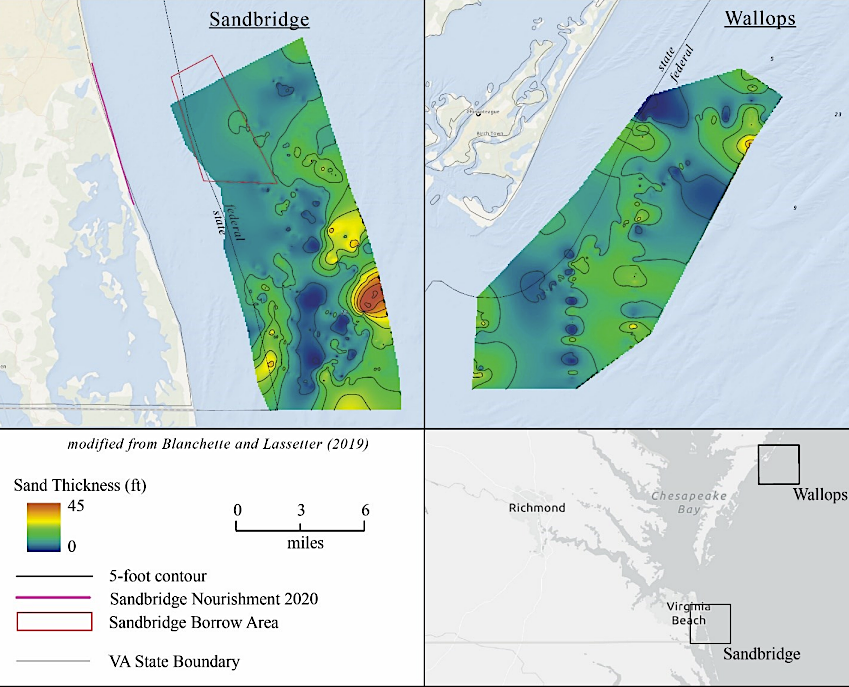

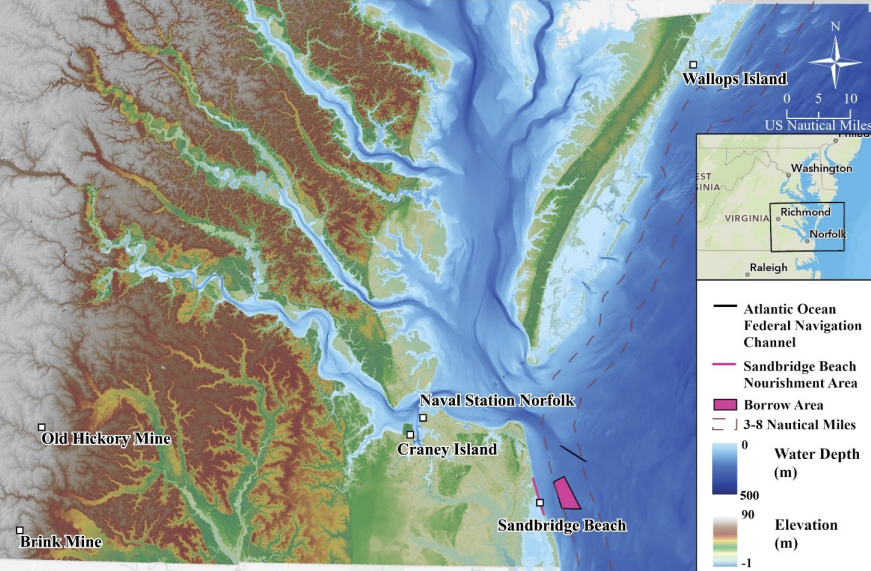

Titanium minerals washed downstream from ore bodies west of the Blue Ridge, and from saprolite in the Piedmont, to the location of the Atlantic Ocean shoreline. As much as five million years ago, the heavy grains of ilmenite, rutile, and zircon were concentrated by wave action in Pliocene Epoch beach deposits now located in Dinwiddie, Greensville, and Sussex counties. Offshore sands include titanium-rich minerals as well as quartz. Dredged sands used for beach replenishment projects could be mined, with titanium separated from the quartz as beaches are nourished.

erosion and sorting has created economically-valuable titanium deposits on the Coastal Plain and Outer Continental Shelf

Source: Virginia Energy, Open File Report 2024-16: A capacity assessment on the recovery of critical and economic minerals from sand used for coastal resilience projects (Figure 1)

Deposits in South Carolina, far from major rivers, suggest that titanium grains were carried by major rivers from the Piedmont and initially deposited on the Continental Shelf. As sea level rose, offshore sand shoals were carried inland. Currents and waves sorted the sands as they were redeposited, enriching them with relatively heavy titanium and zircon grains. When sea level dropped again, the enriched deposits were left on the upland.3

Because the titanium minerals are particularly heavy, the grains are separated from quartz sand by gravity; waves did this naturally when sea level was higher and the ocean shoreline was further west. The Old Hickory Heavy Mineral Sand Deposit has been mined commercially by RGC Mineral Sands and its successor corporation, Iluka Resources.

titanium oxides that eroded from west of the Blue Ridge, and from metamorphic rocks in the Piedmont, have accumulated in sediments on the Coastal Plain

Source: Virginia Department of Energy, HeaderTitanium Occurrences in Virginia

Other wave-concentrated titanium deposits may still be located offshore, underneath the modern ocean. The Virginia Department of Energy has identified the sandbars offshore of Sandbridge, Assateague, and Wallops Island as having the greatest potential for commercial development. At Wallops, for example, if the beach was replenished every 3-7 years then the investment in equipment to separate heavy miverals from submarine sediments might be justified.

The first opportunity to mine deposits naturally enriched with titanium may be associated with beach replenishment efforts, which dredge up the sandbars and barge/pump them onshore to restore beaches from which the sand has eroded. Commercial mining might be possible by sorting out the heavy titanium grain when sand is dredged/pumped, or as it is emplaced on a beach. However the Virginia DEpartment of Energy reported in 2024:4

old beach sands which concentrated titanium-rich minerals have been mined near Emporia

Source: ESRI, ArcGIS Online

Titanium was first valued as a pigment, before being used during the 20th Century in airplanes such as the SR-71 Blackbird where the metal could withstand high temperatures. "Titanium white" pigment was discovered in 1908, and its brilliance revolutionized pigment technology.

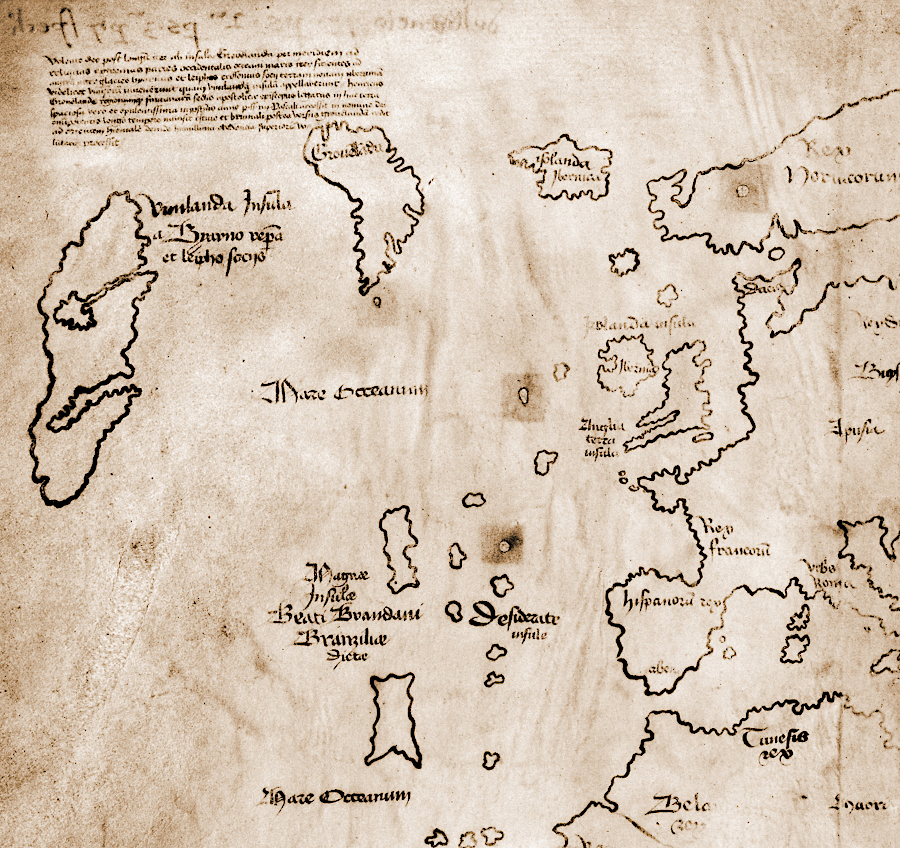

Yale University used the relatively recent development on titanium in inks to determine that its Vinland Map was a fake. The university proposed in 1965 that the map dated from 1440, four centuries after Vikings settled in Newfoundland and 50 years before Columbus crossed the Atlantic Ocean. Within a decade, Yale acknowledged the map could be a modern forgery, but not until 2021 did chemical analysis of the ink conclusively reveal a titanium compound (anatase) that was commercially produced in Norway in 1923.

A 1908 metallurgist was not the first to discover the capacity of titanium to make a bright white color. Around 1530 the Inca started to use titanium dioxide in their geometrical designs on wooden drinking cups. The titanium was extracted from the Giacomo Deposit on the modern Peru-Chile border, where quartz sands had been enriched naturally with the mineral. After 50 years of Spanish occupation, the Inca switched to lead oxide to make their white pigment, and their use of titanium was not recognized until 2018.5

Corrosion-free titanium is a strategic mineral for the aerospace and manufacturing industries in the United States; reliable access to the mineral is a national defense priority. The US military is required by the Specialty Metals Amendment to obtain titanium only from American sources or qualified countries, which include Japan and members of the North American Treaty Organization (NATO).

When Russia invaded Ukraine in 2022, it was providing 15% of the titanium in world trade. The United States imposed sanctions on Russia in response to the invasion, but exempted titanium imports. The Chief Executive Officer of Airbus stated simply that the aerospace industry was dependent upon the mineral:6

the US military does not use Russian titanium for production of warplanes

Source: US Air Force, F-22 Raptor

The Department of Energy funded research into a new process to convert titanium scrap into a powder and recycle it into new products

Based on that new process, in 2022 IperionX Limited announced plans to build a $82 million facility at the Southern Virginia Technology Park in Halifax County to recycle titanium metal scrap. The company examined 100 sites in 30 states before choosing Halifax County. The company's Chief Executive Office highlighted that a skilled workforce and the presence of other manufacturing facilities in Southern Virginia, not the location of titanium, determined where to locate:7

Governor Youngkin noted the significance of titanium recycling:8

In 2023, the Defense Department provided IperionX a $12.7 million grant to scale up the titanium recycling project and build a demonstration plant. After demonstrating the capacity to produce 125 metric tons of titanium powder annually, the plan was to build a facility that could create 10,000 metric tons per year by 2030.

Funding a titanium recycling facility under the Defense Production Act was justified because in 2023 the United States imported 95% of titanium used in manufacturing. The Defense Department included in its news release about the grant:9

discovery of titanium-based ink developed in the 1920's revealed the Vinland map to be a modern forgery, not a product dating from 1440

Source: Wikipedia, Vinland Map

Source: Science Museum of Virginia, Lunch Break Science: Titanium Isotopes in the Acasta Gneiss and the Origins of Plate Tectonics

titanium occurrences occur in bedrock, saprolite, and old beach sands

Source: Virginia Department of Energy, Potential Titanium Occurrences in Virginia