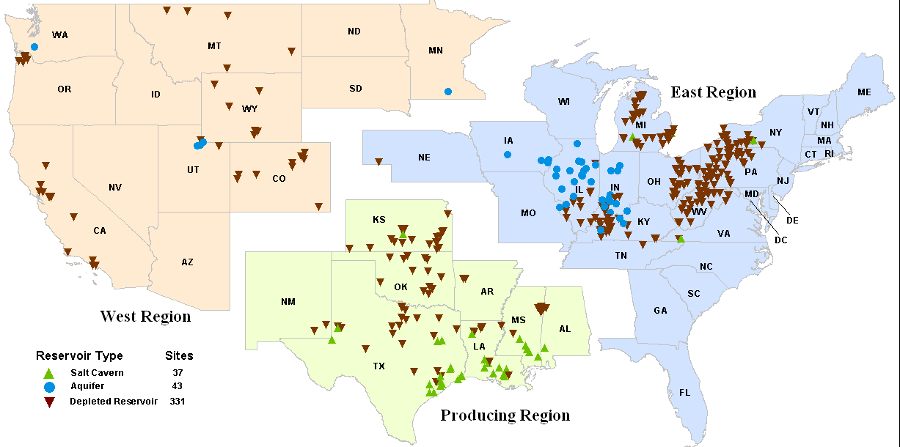

natural gas is stored underground in a depleted reservoir and a salt cavern in Virginia

Source: US Energy Information Administration, Underground Natural Gas Storage

natural gas is stored underground in a depleted reservoir and a salt cavern in Virginia

Source: US Energy Information Administration, Underground Natural Gas Storage

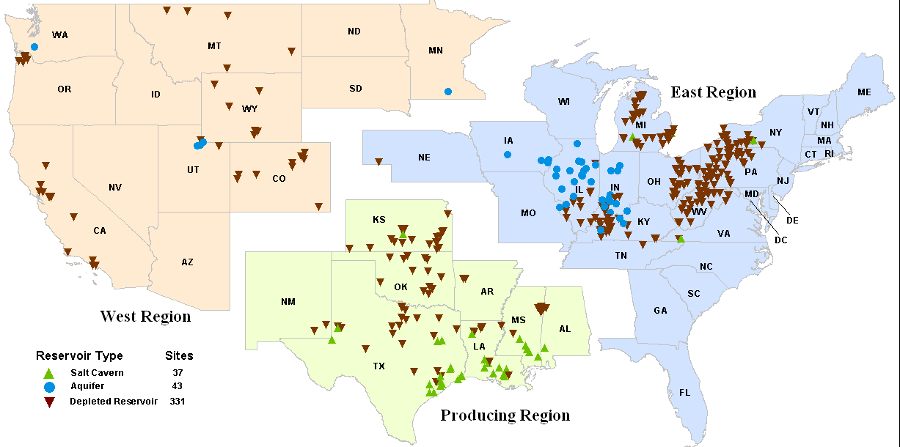

Ever since utilities first started to generate methane by heating coal in the absence of oxygen to create "manufactured" or "coal" gas, there have been many above-ground natural gas storage facilities scattered across the state.

In Richmond, tanks at the Fulton Gas Works stored manufactured natural gas produced from 1856-1972. Manufacture of gas from bituminous coal ceased in the 1950's after Richmond was linked to a natural gas pipeline, but the site was used to store propane until flooding by Hurricane Agnes in 1972 dislodged the propane tanks and demonstrated the risks of that flood plain location.1

coal gas was stored in a large above-ground tank at Fulton Gas Works in Richmond

Source: Library of Virginia, Adolph B. Rice Studio, Fibre Board Container Corp.

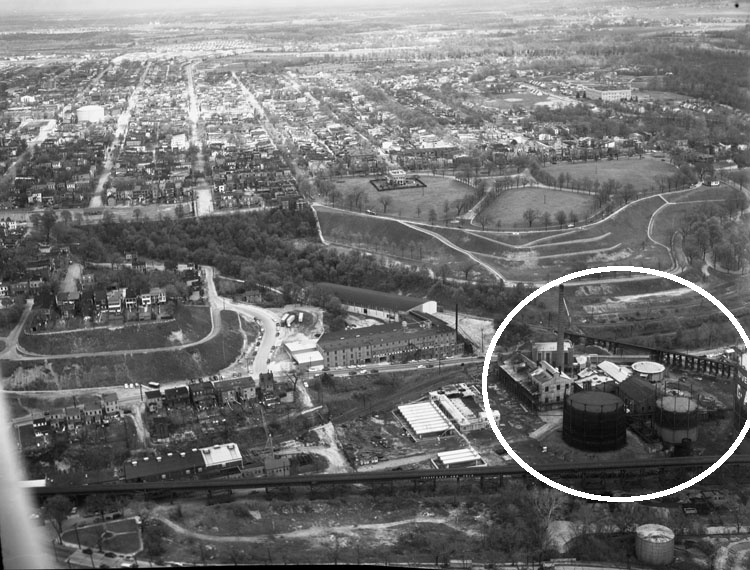

Coal gas is no longer manufactured by local municipalities. Instead, natural gas is extracted from underground formations and delivered to local distribution companies by large interstate transmission pipelines.

remains of the large above-ground tank at Fulton Gas Works in 2017

In Virginia, some local utility companies and two pipelines rely upon storage of natural gas in various forms to supplement deliveries from producing gas wells. When demand is low during the summer, gas is pulled from the pipelines or delivered by rail in tanker cars. The surplus gas is stockpiled in above-ground tanks or underground reservoirs for winter use. Underground gas storage is not a new practice; it was first implemented in 1915.2

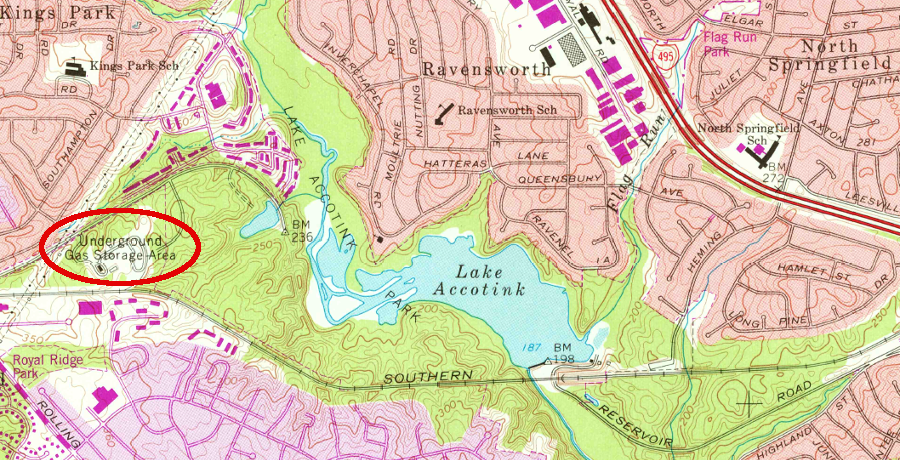

Accumulating gas during the summer enables the local distribution companies to meet high demand during cold snaps. In December-February, demand for heating peaks and can exceed the capacity of the interstate transmission pipelines to deliver gas from the Gulf Coast or the Appalachian gas fields. The stockpiled natural gas is then released from tanks/reservoirs and distributed to customers through the local system of smaller pipes operated by the utility companies.

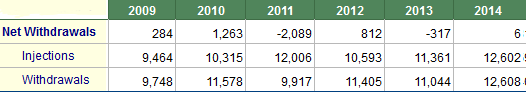

annual natural gas withdrawals from the Saltville and Early Grove reservoirs match annual injections, since storage is designed to balance summer and winter demand

Source: US Energy Information Administration, Underground Natural Gas Storage by All Operators

Selection of a site for above-ground storage is based primarily upon local needs, local zoning, and access to natural gas.

In Roanoke, the local gas utility compresses gas into Liquefied Natural Gas (LNG) and stores it in an above-ground, insulated tank at Tinker Mountain built in 1972. East Tennessee Natural Gas operates a similar LNG facility just south of the Virginia border at Kingsport, Tennessee. Columbia Gas has LNG facilities in Chesapeake and Lynchburg.3

In some places, propane is selectively stored. Natural gas consists of different hydrocarbons. The primary component in natural gas is methane (CH4), along with ethane (C2H6), butane (C4H10, and propane (C3H8). Gas processing plants and oil refineries separate propane and sell it as a distinct product. One cubic foot of propane contains 2,516 BTU (British Thermal Units, a measure of energy) and one cubic foot of natural gas contains 1,030 BTU, so the same volume of propane will provide roughly twice the energy of methane.

Propane (with various percentages of butane, propylene, and butylene) can be cooled to -44°F and compressed into a liquid state, reducing the volume required for storage. Liquid propane can be stored at room temperature in steel cylinders that can withstand pressure of 150 pounds per square inch, and is described as Liquefied Petroleum Gas (LPG) or LP gas.

many rural homes, not connected to a pipeline, store propane in outside tanks

Compressed Natural Gas (CNG), which is used to power buses in urban areas, includes the full mix of methane and other hydrocarbons. Compressed Natural Gas (CNG) is still in the gaseous state. Unlike Liquefied Petroleum Gas (LPG), Compressed Natural Gas (CNG) is still in a gaseous state when inside its steel containers. If cooled below -184°F or as far as -274°F (depending upon the original mixture of gases), it is known as Liquefied Natural Gas (LNG).

Diesel engines generate emissions that reduce air quality, so many warehouses use forklifts with engines powered by Compressed Natural Gas (CNG). Propane is used to fuel outdoor vehicles because in places its cost is lower than diesel, due to reduced engine maintenance. Propane is not used as an energy source for indoor vehicles. If a tank leaked and heavier-than-air propane escaped into the warehouse, the gas could accumulate in a low area and explode. Compressed Natural Gas (CNG) is lighter than air since its primary component is methane, so it is a safer fuel for use indoors.4

On a larger scale, utilities and pipeline companies accumulate and store massive quantities of propane during low-demand periods. At high-demand periods, they can blend propane with compressed air, creating a synthetic natural gas. If not blended with air, the customer might receive a gas that burned too hot for standard furnaces, water tanks, ranges, etc. During periods of peak demand the liquefied and pressurized propane is transformed back into a gaseous state, mixed with air, then injected into pipelines to ensure supplies are not interrupted despite the constraints of interstate transmission lines.

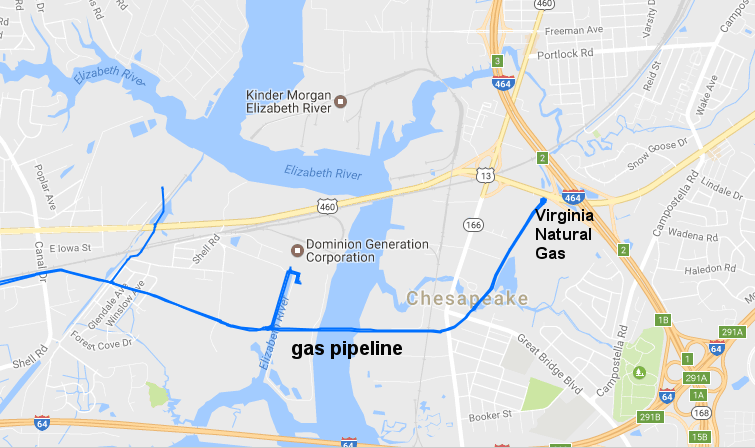

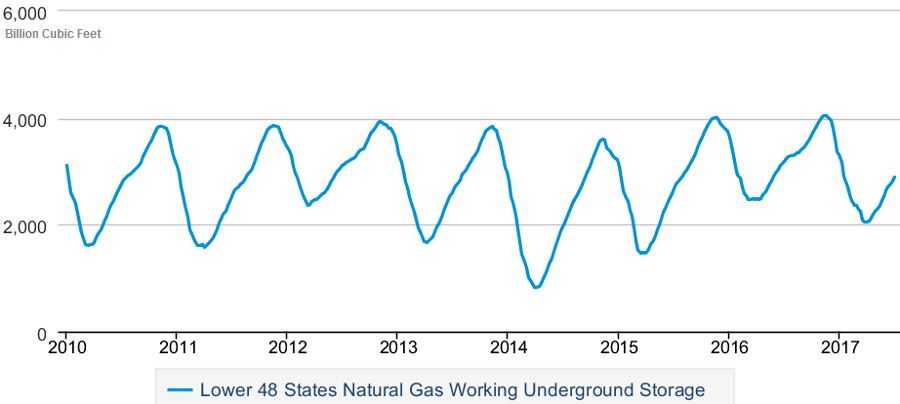

The Virginia Natural Gas utility company operates two propane storage and vaporization facilities in the city of Chesapeake, at the southeastern end of its pipeline. That pipeline is connected to the Columbia Gas Transmission Company's Chesapeake Liquefied Natural Gas (LNG) facility in Chesapeake, allowing for propane-air "peak shaving" facilities to provide a backup supply when demand is greatest in the winter. Other utilities in Virginia operate four other propane-air plants.5

Virginia Natural Gas has a "Peak Shaver" facility that injects propane into the end of the gas pipeline in Chesapeake

Source: ESRI, ArcGIS Online

Because propane can be compressed and distributed by rail and truck, companies can deliver it to customers not connected to any pipeline network. Trains with pressurized tanker cars deliver propane to terminals not near a pipelines.

Propane distributors are not required to be utilities. In the propane business, distributors do not get exclusive service territories and prices are not regulated by the State Corporation Commission. There is no "natural monopoly" that requires state regulation of prices, and propane distributors compete with each other directly in the marketplace.

The extra energy in propane has made it economical for storage and distribution in small cylinders. Compressed propane is sold as a standard retail product. In every suburb, individual houses store propane in one or more cylinders to fuel backyard grills.

Warnings on the containers advise storing them outdoors or in a well-ventilated place, not in a basement where any release of heavier-than-air propane could accumulate and explode. Retail outlets selling cylinders of propane always store the containers outside of buildings. Fire departments recognize that an exploding propane storage tank is a risk at many locations, and are trained to allow gas coming from a leaking tank to burn away. Extinguishing a fire without stopping a leak would allow more gas to accumulate and potentially explode, causing greater damage to life and property.6

propane canisters are sold like plants outside a Wal*Mart north of Leesburg, with a fire extinguisher nearby

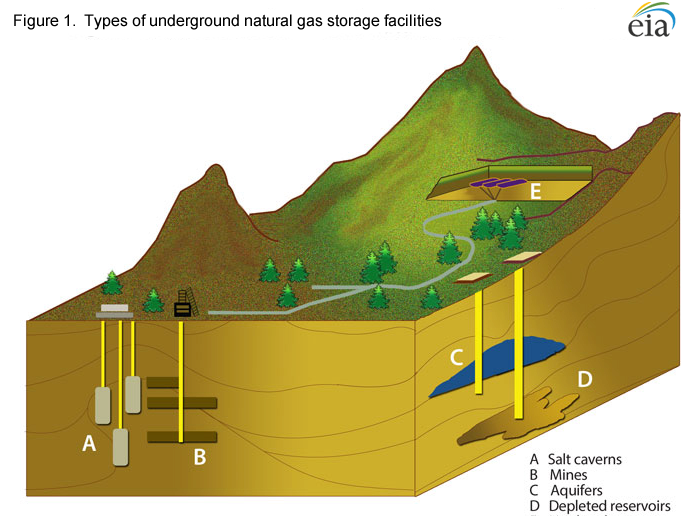

Selecting a site for underground natural gas storage is more complex that siting a propane storage tank. Underground storage requires consideration of local geology, as well as local needs, local zoning, and access to natural gas. Underground natural gas storage comes in two versions: natural and artificial.

Different sedimentary rock formations in Virginia have been natural storage reservoirs for 150-300 million years. Coal beds in the Appalachian Plateau, the Oriskany sandstone in Rockingham County, and the Triassic sandstones and shales in the Taylorsville Basin northeast of Fredericksburg have trapped natural gas that formed as ancient marine plankton and freshwater vegetation decomposed.

Several underground natural gas reservoirs in Virginia are far more recent. In the 20th Century, gas storage was attempted in an old railroad tunnel near Charlottesville, in an old gas field at Early Grove in Scott and Washington counties, in the evaporite deposits from which brine was extracted at Saltville, and in a cavern excavated in granite at Ravensworth in Fairfax County.

Virginia does not have a storage site relying upon aquifers. Aquifer storage is more expensive to develop and maintain, requiring expensive assessment of the geologic formations to determine suitability for gas storage. In addition, aquifers require a greater amount of "cushion gas" that must stay underground, and can not be extracted and used each season.7

One of the oddest attempts to create a natural gas storage reservoir was the attempt in the 1950's to repurpose Claudius Crozet's railroad tunnel under the Blue Ridge. The original Blue Ridge Tunnel had been constructed in 1858, then abandoned in 1944 when a new tunnel was bored through the mountain parallel to it to accommodate wider locomotives.

Within the abandoned tunnel, Bottled Gas Corporation constructed two concrete bulkheads to create an artificial storage tank. The two bulkheads, one 10' thick and the other 14' thick, isolated a 2,000' long section of the tunnel in which propane was to be stored under pressure.

walls built to store natural gas in the Blue Ridge Tunnel included pipes now used by explorers preparing the site for public visits

Source: WVPT, The Blue Ridge Tunnel

That section of the tunnel was cut through the Catoctin greenstone of the Blue Ridge, which had been so hard for the Irish laborers to cut through with hand-powered drills and black powder. The gas company thought the tunnel would be as tight as a bottle. However, there was no brick or concrete coating to prevent gas escaping through the cracks in the bedrock, the tunnel had too many leaks to store gas, and the project was cancelled before completion.

Pipes built into the bulkheads for planned injection/removal of the gas remained, and were large enough for intrepid explorers to crawl through the entire Crozet tunnel. Nelson County officials obtained funding from the Commonwealth Transportation Board to remove the bulkheads and create a tourist attraction. When opened to the public, hikers will walk underneath Afton Mountain through the successful original railroad tunnel and the failed gas storage project.8

concrete bulkhead at eastern edge of natural gas storage project in the Blue Ridge Tunnel

Source: Virginia Department of Transportation, Gas Bulkhead at the East Portal

Artificial underground storage includes small tanks used for a single house, and large tanks used for distribution of propane to entire subdivisions.

propane can be trucked to areas not connected to a pipeline, and distributed from underground tanks to an entire subdivision

Source: Propane Education & Research Council, Community Propane Systems

There are also massive underground gas storage projects designed to supplement supplies from pipelines during winter months. These include old sandstone reservoirs that once supplied natural gas, salt formations, and excavated caverns.

in Virginia, natural gas is stored in depleted oil/gas reservoirs, in excavated salt caverns, and in caverns excavated within hard bedrock

Source: US Energy Information Administration, The Basics of Underground Natural Gas Storage

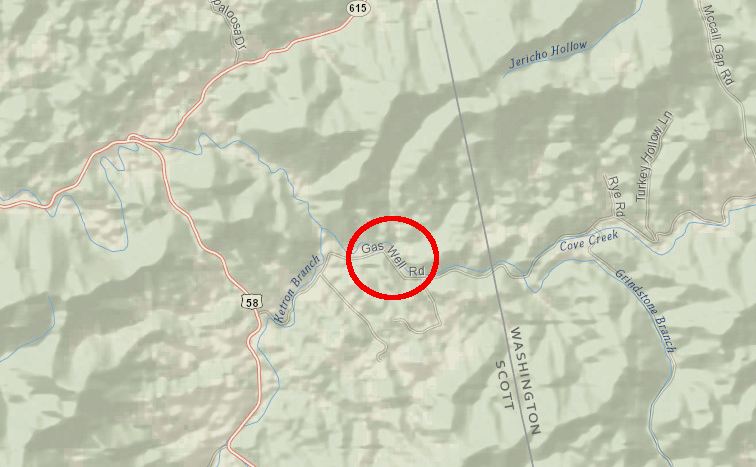

The Early Grove anticline in Scott and Washington counties was first developed in 1931. Natural gas from the sandy zones of the Little Valley Limestone and shales was transported to Bristol through a 4-inch pipeline. The field was revitalized by new drilling in 1980, but production was limited.9

The Early Grove gas field ended up with a second life as a storage reservoir. The withdrawal of natural gas from the bedrock did not result in compaction of the reservoir; the voids between the rock particles remained.

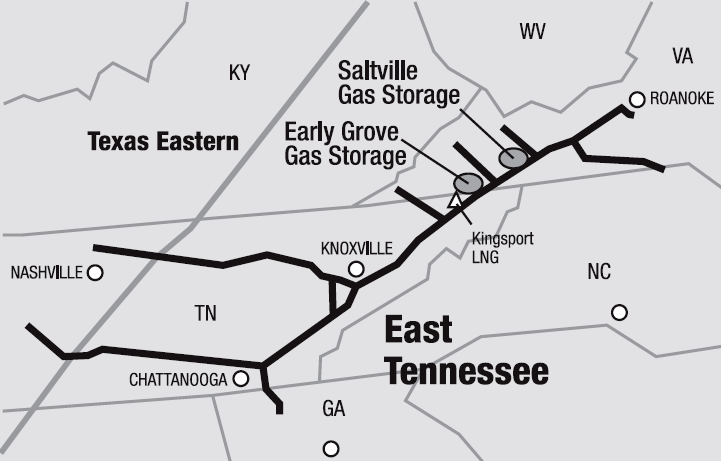

After the East Tennessee Natural Gas pipeline was constructed through southwestern Virginia, the depleted field was converted into Virginia's first natural gas storage reservoir in 1990. By 2009, it had a "working capacity" of 1.4 Billion cubic feet (Bcf) of natural gas. It could deliver from storage 20,000 Million cubic feet/day (Mcf), adding pressure to the pipeline when customer demand was high.10

The Bergton gas field in Rockbridge County is also a depleted reservoir, but it has not been repurposed for storage. Former oil and gas reservoirs in West Virginia have been developed for seasonal storage, and those fields are closer to the pipeline network that delivers gas to customers.

place names at the Early Grove field offer a clue about the history of hydrocarbon development in Scott County

Source: ESRI, ArcGIS Online

The Saltville storage reservoir was created originally 300 million years ago, when modern Smyth County was underwater. Salt water washed into a basin and evaporated, in a repeating cycle that created beds of "evaporites" later named the Little Valley Limestone and the Maccrady Shale. The ocean later covered the deposits. Various layers of limestone, shale, and other rocks ended up on top, then eroded away, while the layers were faulted and cracked by tectonic forces.11

Since at least the Ice Age, groundwater circulating through those deposits has emerged at the surface in springs. The groundwater reaching the surface was enriched in salt, and the naturally-occurring brine has attracted animals to salt licks.

In the 1780's, investors from Tidewater (including the husband of Patrick Henry's sister) started digging shallow wells to extracted the brine. The King family floated salt down the North Fork of the Holston River to Tennessee, creating a settlement at Kingsport and sending product further down the Tennessee River to the developing city of Chattanooga. During the Civil War, brine was evaporated in kettles to produce salt for preserving meat and other food.

In the 1890's, deeper wells were used to pump brine to the surface. Instead of evaporating it for production of table salt (sodium chloride), the brine was processed to create chlorine and caustic soda chemicals for various industrial uses. The industrial operations spurred the creation of a company town, Saltville in Smyth County. Throughout eight decades of extensive pumping of brine, voids were created underground as the fluid with dissolved salt was carried to the surface for processing.

In 1972, the Olin Corporation shut down its operations at Saltville. The equipment was outdated and the company had other facilities operating at a lower cost, but blamed the shutdown on a requirement by the State Water Control Board to reduce the high levels of salt dscharged into the North Fork of the Holston River. The chemical plant later became a Superfund site, due to extensive levels in the soil of the mercury that had been used in the chlorine production process.12

The salt formation was repurposed as a storage field for natural gas. In 1996 the Environmental Protection Agency issued Underground Injection Control permits, so the underground voids created by earlier salt mining could be expanded.

Water was pumped 2,000-4,000 feet down, far below the depth of the drinking water aquifer, to dissolve more salt. The resulting brine was pumped back to the surface, creating additional storage capacity deep underground. The brine brought to the surface was evaporated to create commercial products for agriculture and swimming pool maintenance. That effort cost over $70 million and created about 150 new local jobs.13

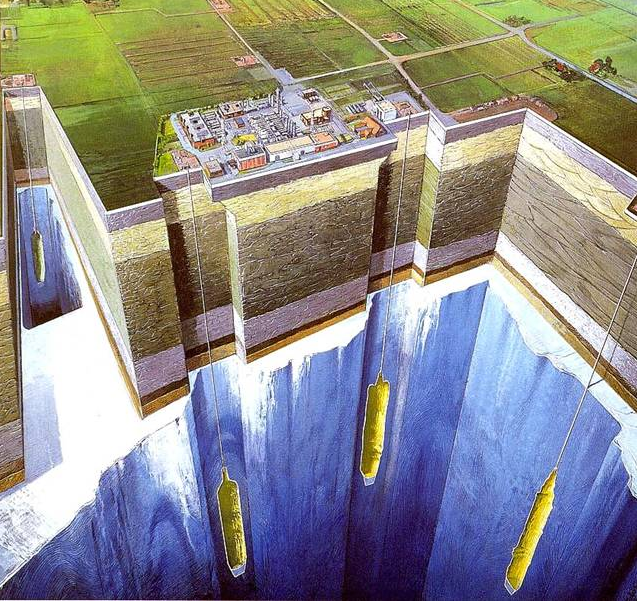

similar to this illustration, the underground gas storage caverns at Saltville were excavated by injecting water and dissolving salt

Source: US Energy Information Administration, Salt Cavern Underground Natural Gas Storage Reservoir Configuration

Each summer at Saltville, natural gas transported in the East Tennessee Natural Gas pipeline is injected into the salt beds. The pipeline and storage facility were part of a company called Spectra, until that company was acquired by Enbridge in 2017.

The pressurized, injected gas displaces any remaining brine and forces it to the surface. Natural gas molecules fill the spaces once occupied by salt crystals or water. Gas stored at Saltville comes from the Gulf Coast, nearby coalbed methane wells in Appalachian coal fields, and from natural gas wells drilled into Appalachian shales such as the Marcellus formation.

When there is a surge in demand during the winter, the stockpiled natural gas is extracted and piped to customers. The Saltville caverns offered 5.5 billion cubic feet (Bcf) of natural gas storage capacity when Spectra purchased the underground storage system in 2008, and further excavation (by injecting water to dissolve salt and pumping out the brine) has increased capacity since then. The Saltville reservoir can deliver 300 million cubic feet of natural gas daily to customers, supplementing delivery from other sources on the pipeline.14

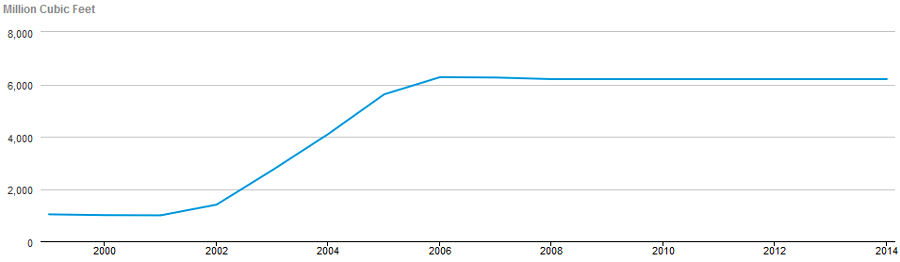

gas storage capacity in the caverns at Saltville was expanded from 1 billion cubic feet in 1999 to 6.2 billion cubic feet in 2006

Source: Energy Information Administration, Virginia Natural Gas Underground Storage Salt Caverns Capacity

That 300 million cubic feet of natural gas made available daily is significant, but only a small percentage of total gas used each year within the state. All Virginia customers in 2012 used nearly 400Bcf of natural gas, and:15

Creating an above-surface storage reservoir would have been more expensive than utilizing the geologic formations underneath Saltville, but the underground geology was not ideal. Because the original horizontal salt bed deposits were disrupted by tectonic faulting and broken up into underground blocks, the solution caverns ended up being smaller than anticipated. After determining that at least one was 70% filled with rubble, the natural gas storage company reduced its estimate of volume by 30%.16

the Early Grove depleted gas storage field is managed in synch with operations of the Saltville gas storage facility and demand on the East Tennessee Natural Gas pipeline

Source: Spectra, Saltville Gas Storage

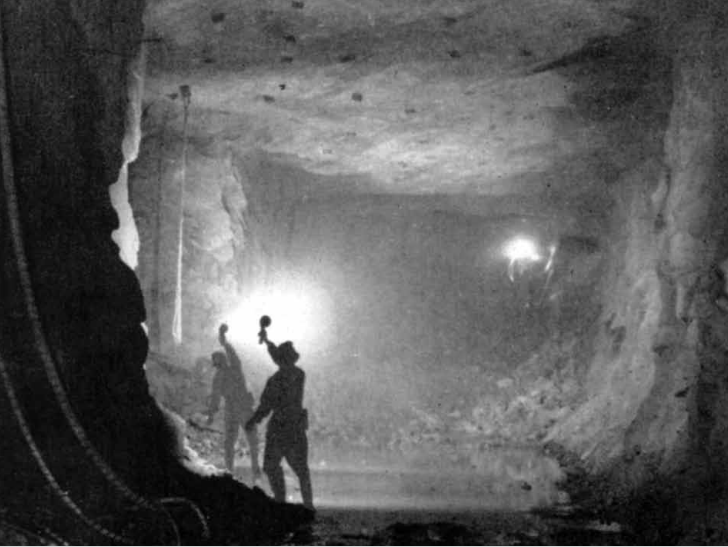

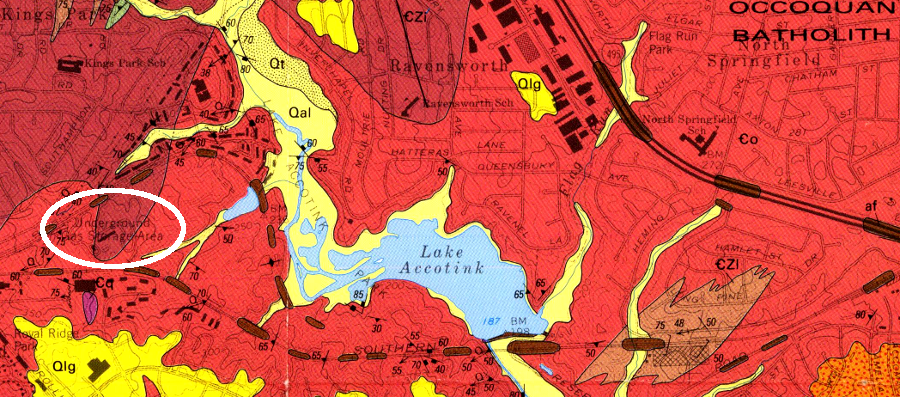

In 1962, Washington Gas excavated an underground cavern in Fairfax County to store 13 million gallons of Liquefied Petroleum Gas (LPG). The Ravensworth Station reservoir was carved out of the nearly 500-million year old Occoquan granite bedrock west of Lake Accotink Park. The cavern was constructed first by drilling a 42-inch wide hole down 400 feet, then lowering one man to the bottom to start the excavation. The underground hole was gradually widened enough for pieces of equipment less than 42-inchs wide to be lowered down through the pipe. The cavern has a 25-foot high ceiling, with pillars of granite left at different spots to support the roof.

in the early 1960's, Washington Gas carved out a cavern near Accotink to store liquid propane

Source: Washington Gas, Growing with Washington, Part 2 - A History of Washington Gas 1948-2012

The Southern Railway delivered over 400 tanker cars to a siding near Springfield for the initial filling of the cavern. There is little indication of the natural gas storage facility on the surface, other than the compressors which mix air into the propane to create a mixture with the appropriate burning characteristics.17

liquid propane is stored in a cavern excavated by Washington Gas in Fairfax County

Source: ESRI, ArcGIS Online

A geologist who managed the site noted that during excavation, workers wore raincoats due to water leaking into the cavern. That provided a clear indication that the bedrock was fractured, but the walls were not sealed with cement of any kind. To keep the propane (compressed into its liquid state) in the cavern, Washington Gas relies upon a water cap to maintain geostatic pressure.

Washington Gas selected the Occoquan Granite for its Ravensworth Station propane storage cavern in Fairfax

Source: US Geological Survey, Geologic map of the Annandale quadrangle, Fairfax and Arlington Counties, and Alexandria City, Virginia (1986)

Water that leaks into the cavern is constantly extracted and injected into the soil, and the company ensures the soil stays saturated even in a drought. Propane does not dissolve easily in water so nearly all of the Liquefied Petroleum Gas stays trapped in the cavern. Traces of propane have been identified in the soil after a nearby resident notices the smell of "swamp gas" in an area without a swamp, and tiny bubbles may escape into Accotink Creek. Most likely, that propane was brought to the surface with water pumped out of the cavern, and there is not a series of cracks in the granite stretching 400 feet up to the surface.18

Washington Gas excavated the Ravensworth Station propane storage cavern in Fairfax County where the Southern Railroad could deliver propane in tanker cars

Source: US Geological Survey, Annandale 1:24,000-scale quadrangle map (1965)

The greatest risk of an uncontrolled release of gas from an underground reservoir involves the wells used to inject and extract the gas. The steel tubes and cement in the well can crack. Under the wrong circumstances, even blowout preventers on a well may not control the flow.

The Federal Energy Regulatory Commission has noted "The walls of a salt cavern also have the structural strength of steel" and the Federal government uses salt domes in Texas and Louisiana for the Strategic Petroleum Reserve, but salt caverns and underground rock formations are not risk-free sites for storage of natural gas.

A complex of 125 caverns at Mont Belvieu, Texas has experienced a significant number of leaks and accidents. After a 1980 leak and explosion, and the discovery that brine had contaminated the community's drinking water supply, a consortium of petrochemical companies funded the relocation of 200 families from the salt dome known as Barbers Hill.

In 1992, natural gas liquids leaked from a salt dome storage field nearby at Brenham, Texas. The dome was over-filled by a pipeline company that lacked a safety culture, had not installed an effective shut-off system to stop leaks, and failed to recognize that the site's storage capacity had been exceeded. Vapor that escaped the well ignited in a "bomb-like blast" that registered between 3.5 and 4.0 on the Richter scale. Three people were killed and 21 more were injured, but the facility was repaired and returned to service a year later.19

A 2001 leak at a salt storage site near Hutchinson, Kansas created an underground gas plume that moved seven miles underground. The leak occurred in a well casing above the salt dome; the walls of the reservoir that had been excavated in the salt remained intact. Once the gas escaped the well, an impervious layer of rock prevented further travel up to the surface until the gas encountered abandoned brine wells that had not been plugged. The gas produced water and gas geysers in the town, with two explosions and fatalities. As a result, the Yaggy gas storage facility in Kansas was shut down.

In 2004, a well at the Moss Bluff salt cavern near Houston caught fire at a leak above the blowout preventer. It burned for six days until the gas supply in the dome (worth $36 million) was exhausted.

In 2015, a well at the Aliso Canyon Storage Field near Los Angeles began leaking. That underground reservoir had been developed in a depleted oil and gas field. The methane that escaped over the next four months was already odorized, so a nearby neighborhood was evacuated due to the smell as well as safety concerns. The problem was associated with the well; there were no new cracks in the geologic formations allowing gas to reach the surface. After installing new steel piping and casing in wells and completing mechanical integrity tests successfully, SoCalGas proposed re-opening the underground reservoir in 2017.

The 1994 explosion at the Brenham salt dome spurred the state of Texas to issue regulations with higher safety standards for underground storage facilities. State regulations were also tightened in Kansas after the 2001 explosion at Hutchinson, but a Federal court ruled in 2011 that the state could not regulate underground storage facilities that stockpiled gas which had been piped across state lines.

Only the Federal government had that authority. The responsible Federal agency, the Pipeline and Hazardous Materials Safety Administration in the US Department of Transportation, focused on pipeline safety and did not develop different standards for underground storage sites. The uncontrolled release of methane at Aliso Canyon finally triggered the Federal government to issue standards for underground gas storage facilities.20

The Environmental Protection Agency (EPA) records the following data regarding underground natural gas storage in Virginia:21

One future possibility is the use of depleted gas reservoirs for storage of hydrogen. In 2023, the US Department of Energy awarded Virginia Tech a $1.5 million grant for "Assessment of Subsurface Hydrogen Storage in Depleted Gas Fields of Appalachia." Focus was on storage in the Berea, Big Lime, and fractured Marcellus geologic formations.22

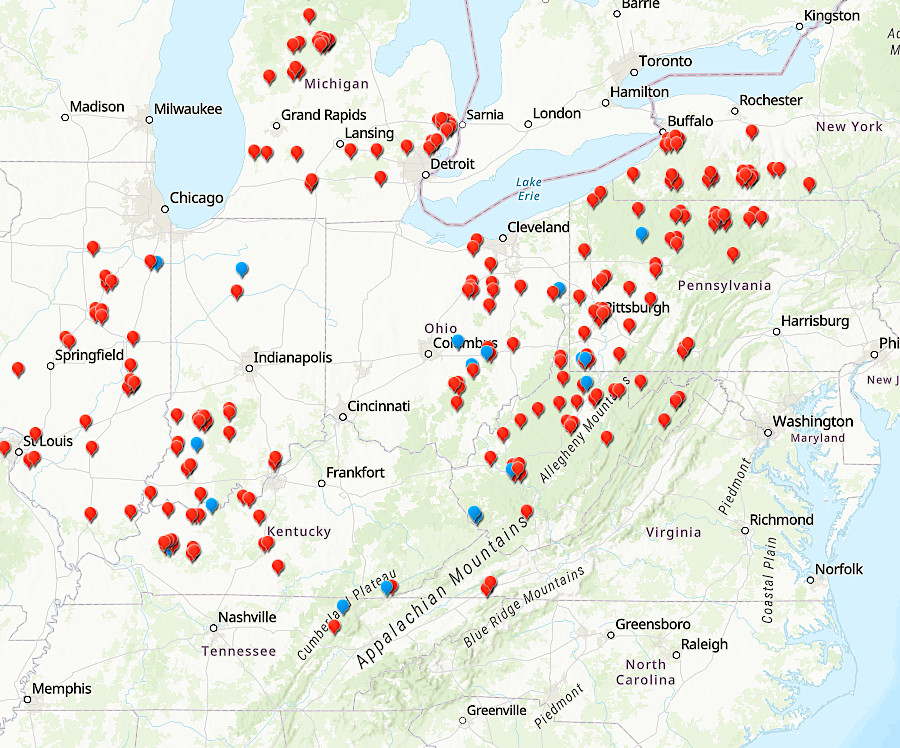

the two underground natural storage facilities in Virginia are near Abingdon

Source: Environmental Protection Agency (EPA), EnviroMapper

inventories held in underground storage facilities decline as gas is extracted in the winter to supplement supplies brought by pipeline

Source: Energy Information Administration, Lower 48 States Natural Gas Working Underground Storage

Virginia Natural Gas operates a peak shaver facility in Chesapeake, drawing on the Columbia Gas Liquified Natural Gas storage facility nearby

Source: ESRI, ArcGIS Online

underground natural storage facilities are common in the Midwest, but rare east of the Appalachians

Source: Environmental Protection Agency (EPA), EnviroMapper

1. Jeff Eastman, "Fulton Gas Works Site Development Plan for the National Slavery Museum in Richmond, Virginia," Virginia Commonwealth University, 2008, p.11, http://murp.vcu.edu/projects762/S08/S08_Fulton_Gas_Works_Site_Development_Plan.pdf (last checked April 24, 2017)

2. "Natural Gas Storage - Background," Federal Energy Regulatory Commission, https://www.ferc.gov/industries/gas/indus-act/storage/background.asp (last checked May 8, 2017)

3. "History," RGC Resources, http://www.roanokegas.com/aboutus/history.html; "Community Facilities and Services," Botetourt County Comprehensive Plan 2010, p.89, http://www.botetourt.org/government/documents/cp_upd/botco_final_facilsandsvcs.pdf; "US Pipelines, Spectra Energy, http://www.spectraenergy.com/Operations/US-Natural-Gas-Operations/US-Pipelines/East-Tennessee-Natural-Gas/; "Certificated Natural Gas Service Areas," Columbia Gas, https://www.columbiagasva.com/docs/default-document-library/serviceterritorymap.pdf; "LNG and Propane," Southern Company Gas, http://www.aglresources.com/about/LNG.aspx/a> (last checked May 8, 2017)

4. "Propane Basics," US Department of Energy, May 2016, http://www.afdc.energy.gov/uploads/publication/propane_basics.pdf; "Propane Vs. Natural Gas," Propane 101, http://www.propane101.com/propanevsnaturalgas.htm; "What's the difference between CNG, LNG, LPG and Hydrogen?," Alternative Fuel Systems, http://www.afsglobal.com/faq/gas-comparisons.html (last checked May 7, 2017)

5. "LNG and Propane," AGL Resources, http://www.aglresources.com/about/LNG.aspx; "Distribution Operations," Virginia Natural Gas, http://www.aglresources.com/about/distribution_vir.aspx; "Preliminary Assessment of a Propane-Air Backup System for the Anchorage, Alaska, Area," Argonne National Laboratory, February 2012, Table 1, p.2, http://www.ipd.anl.gov/anlpubs/2012/07/73792.pdf (last checked July 14, 2015)

6. "Fire Department Response To Natural Gas Emergencies," Firehouse, November 8, 2005, http://www.firehouse.com/article/10504146/fire-department-response-to-natural-gas-emergencies (last checked May 6, 2017)

7. "Current State of and Issues Concerning Underground Natural Gas Storage," Federal Energy Regulatory Commission, September 30, 2004, p.5, https://www.ferc.gov/EventCalendar/Files/20041020081349-final-gs-report.pdf (last checked May 9, 2017)

8. "Long-abandoned Blue Ridge Tunnel could partially reopen within six months," C'Ville Weekly, September 25, 2013, http://www.c-ville.com/long-abandoned-blue-ridge-tunnel-could-partially-reopen-within-six-months/#.U7B9XbGoqfM; "Brutal history of Blue Ridge Tunnel's construction topic of gathering," Daily Progress, September 15, 2013, http://www.dailyprogress.com/news/local/brutal-history-of-blue-ridge-tunnel-s-construction-topic-of/article_9ae75114-1e5b-11e3-abe8-001a4bcf6878.html; "150-Year-Old Tunnel Could Reopen for Hiking Trail," Construction Equipment Guide, July 20, 2005, http://www.constructionequipmentguide.com/150-year-old-tunnel-could-reopen-for-hiking-trail/5892; "Dormant Tunnel Comes Back to Life," WEMC, August 2, 2016, http://wmra.org/post/dormant-tunnel-comes-back-life#stream/0; Christopher M. Bailey, Shelley Jaye, From the Blue Ridge to the Beach: Geological Field Excursions Across Virginia, Geological Society of America, 2017, p.67, https://books.google.com/books?id=_BFBDgAAQBAJ (last checked April 22, 2017)

9. Paul Averitt, "The Early Grove Gas Field, Scott and Washington Counties, Virginia," Virginia Geological Survey, Bulletin 56, 1941, p.3, https://www.dmme.virginia.gov/commerce/ProductDetails.aspx?ProductID=2300; Robert C. Milici, "Oil And Gas Exploration And Development In Virginia, 1979-1988," Virginia Minerals, Volume 36 Number 1 (February 1990), p.4 (last checked July 14, 2015)

10. "Oil and Gas," Virginia Department of Mines, Minerals and Energy, http://www.dmme.virginia.gov/commercedocs/OILANDGAS.pdf; "Underground Natural Gas Storage by All Operators," US Energy Information Administration, http://www.eia.gov/naturalgas/annual/data/eia191a.xls (last checked July 14, 2015)

11. Bruce W. Nelson, "Mineralogy of the Maccrady Formation Near Saltville, Virginia," American Journal of Science, The Cooper Memorial Volume 27-A, p.547, http://earth.geology.yale.edu/~ajs/1973/ajs_273A_11.pdf/539.pdf (last checked July 14, 2015)

12. Jeffrey C. Weaver, Saltville, Arcadia Publishing, 2006, p.33, https://books.google.com/books?id=wigzzrz0e_YC; "Saltville, Virginia: A Company Town Without a Company," Governing, August 2012, http://www.governing.com/topics/economic-dev/gov-saltville-virginia-company-town.html (last checked July 14, 2015)

13. "Saltville helped turn abandoned caverns into much-needed jobs," Virginia Town & City, Virginia Municipal League, September 2003, http://transformgov.org/en/knowledge_network/documents/kn/document/4631/saltville_helped_turn_abandoned_caverns_into_muchneeded_jobs; "Statement of Basis for U.S. Environmental Protection Agency (EPA) Underground Injection Control (UIC) Class III G Injection Well Permit Identified as VAS3G931BSMY for USC Saltville Brine, LLC," US Environmental Protection Agency, April 8, 2014, http://www.epa.gov/reg3wapd/pdf/public_notices/TexasBruneSOB2012.pdf (last checked July 14, 2015)

14. "Sustainable Growth: 2008 Annual Report," Spectra Energy Partners, 2008, p.5, https://infopost.spectraenergy.com/downloads/Storage_brochure_for_web_10-18-11.pdf; "Saltville Gas Storage," Spectra, http://www.spectraenergy.com/Operations/Storage/Saltville-Gas-Storage/ (last checked July 14, 2015)

15. "2014 Virginia Energy Plan," Virginia Department of Mines, Minerals and Energy, Section 3-1, http://www.dmme.virginia.gov/DE/2014_VirginiaEnergyPlan2.shtml (last checked July 14, 2015)

16. "Capacity at VA Storage Facility 30% Lower Than Anticipated," Natural Gas Intelligence, October 8, 2007, http://www.naturalgasintel.com/articles/76143-capacity-at-va-storage-facility-30-lower-than-anticipated (last checked June 28, 2014)

17. "Gas Firm Completes $5.6 Million Project," Washington Post, November 14, 1963, p.C7; "Natural Gas Shipment," Southern Railfan, 1963, http://southern.railfan.net/ties/1963/63-10/gas.html; Richard P. Tollo (ed.), From Rodinia to Pangea: The Lithotectonic Record of the Appalachian Region, Geological Society of America, 2010, p.649, https://books.google.com/books?id=CQoeMsyDNPYC; "'Entering the

Big Leagues' - Chapter II 1960-1969," Growing with Washington. Washington Gas, https://www.washingtongas.com/-/media/d2067877df1e446991e9bece0a1749da.pdf; "Washington Gas Calls Up Reserves from the Midwest," Washington Post, https://www.washingtonpost.com/archive/business/1977/02/05/washington-gas-calls-up-reserves-from-the-midwest/554c0485-2c54-40cf-a7b2-a67e10b23246/ (last checked May 9, 2017)

18. "Propane Trace Found in Soil of Fairfax Area," Washington Post, October 19, 1973, p.C6, personal communication, Washington Gas geologist, April 20, 2017

19. "Chemicals in Salt Caverns Hold Pain for Texas Town," New York Times, November 28, 1988, ; "On Edge Of Houston, Underground Caverns Store Huge Quantities Of Natural Gas Liquids," Houston Public Media, October 19, 2015, http://www.houstonpublicmedia.org/articles/news/2015/10/19/124674/on-edge-of-houston-underground-caverns-store-huge-quantities-of-natural-gas-liquids/; "Safety Questions Pepper Salt Domes," Chicago Tribune, May 10, 1992, http://articles.chicagotribune.com/1992-05-10/news/9202110568_1_mont-belvieu-salt-dome-leak; "Salt dome explosion: 20 years later," Wichita Eagle, April 7, 2012, http://www.theeagle.com/blogs/fajitas_for_one/salt-dome-explosion-years-later/article_cab6128c-019b-11e2-8e7e-0019bb2963f4.html (last checked May 9, 2017)

20. M. Lee Allison, "Hutchinson, Kansas: A Geologic Detective Story," Geotimes, October 2001, http://www.geotimes.org/oct01/feature_kansas.html?hc_location=ufi; "Gas Storage Field Erupts Under Hutchinson, Kansas," Natural Gas Intelligence, January 29, 2001, http://www.naturalgasintel.com/articles/95819-gas-storage-field-erupts-under-hutchinson-kansas; John M. Hopper, "Gas Storage and Single-Point Failure Risk," Shale Property Rights, 2013, p.1, http://www.shalepropertyrights.com/blog/wp-content/uploads/2013/03/article_singlepointfailurerisk.pdf; "Current State of and Issues Concerning Underground Natural Gas Storage," Federal Energy Regulatory Commission, September 30, 2004, p.6, https://www.ferc.gov/EventCalendar/Files/20041020081349-final-gs-report.pdf; "Aliso Canyon Storage Facility Progress Report," SoCalGas, January 13, 2017, https://www.socalgas.com/1443740398529/aliso-progress-report-01302017.pdf; "Underground Natural Gas Storage," Pipeline and Hazardous Materials Safety Administration, https://primis.phmsa.dot.gov/ung/index.htm; "Lawsuit leaves large gas storage fields in Kansas unregulated," Wichita Eagle, October 2, 2011, http://www.kansas.com/news/article1071558.html (last checked May 9, 2017)

21. "Underground Natural Gas Storage," EnviroMapper, Environmental Protection Agency, https://www.arcgis.com/apps/mapviewer/index.html?layers=7671b53ed8b3475f90395bf99fc81403 (last checked December 19, 2021)

22. "Additional Selections for Funding Opportunity Announcement 2400: Clean Hydrogen Production, Storage, Transport and Utilization to Enable a Net-Zero Carbon Economy (Round 3)," US Department of Energy, August 17, 2023, https://www.energy.gov/fecm/additional-selections-funding-opportunity-announcement-2400-clean-hydrogen-production-0 (last checked August 21, 2023)

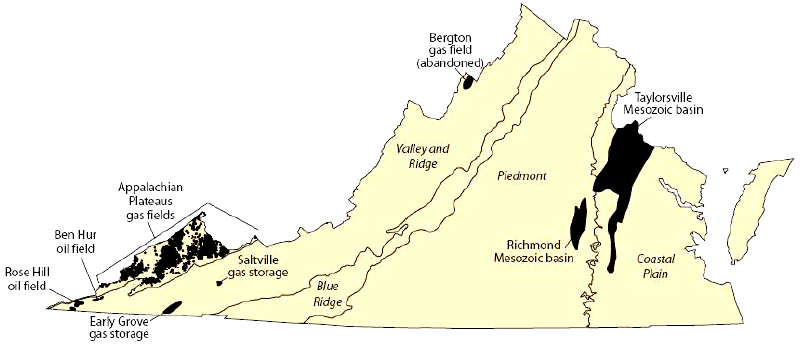

location of potential petroleum resources in Virginia (and two natural gas storage reservoirs)

Source: US Geological Survey, Assessment of Undiscovered Natural Gas Resources in Devonian Black Shales, Appalachian Basin, Eastern U.S.A. (Open-File Report 2005-1268)