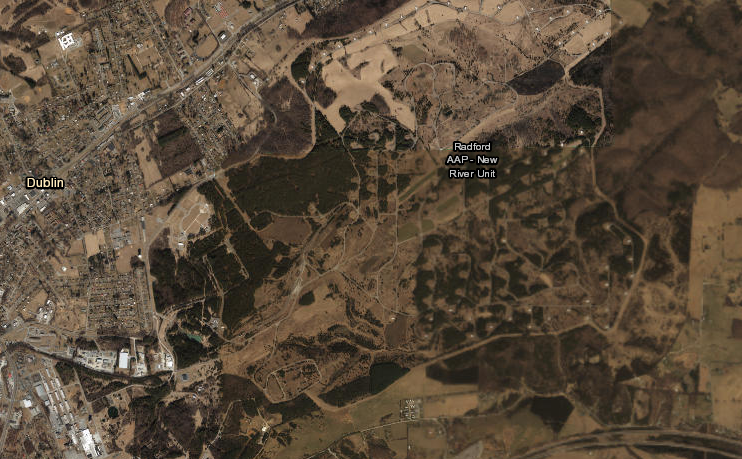

the Main Manufacturing Area of the Radford Army Ammunition Plant is located along the New River in Pulaski and Montgomery counties

Source: Virginia Geographic Information Network (VGIN), VBMP 2011 WGS Web Mercator (VGIN)

the Main Manufacturing Area of the Radford Army Ammunition Plant is located along the New River in Pulaski and Montgomery counties

Source: Virginia Geographic Information Network (VGIN), VBMP 2011 WGS Web Mercator (VGIN)

As World War Two started in Europe, the US Government built multiple facilities to increase its capacity to manufacture ammunition. Two government-owned, contractor-operated facilities were built on the New River, far from the Atlantic Coast and any threat from attack. The Federal government acquired 40 farms from private landowners.

Criteria for selecting sites for new ammunition manufacturing were:1

part of the Radford Arsenal was near Dublin, and part was in Horseshoe Bend

Source: US Geological Survey (USGS), Government housing project built for defense workers in Radford, Virginia

The 4,111-acre Radford Ordinance Works made smokeless powder in a bend of the New River. It expanded during the war to make peritolite, black powder, triple-base powder, rolled powder, 2,4,6-Trinitrotoluene (TNT), and nitroglycerine. Key ingredients were cotton and wood pulp for cellulose, nitric acid, and sulfuric acid.

The Hercules Powder Company built and operated the facility. By the end of World War Two, it included 870 buildings, including a Central Power House with four coal-fired boilers for generating heat and electricity. A natural gas power plant replaced the coal-fired power plant in 2017.

The War Department also funded construction of new houses for the workers.

new housing was needed at the start of World War II for workers at the Radford Army Ammunition Plant

Source: Library of Congress, Government housing project built for defense workers in Radford, Virginia (photo by Marion Post Wolcott, October 1941)

Some buildings were designed to last 20 years, but most were constructed to "temporary" standards assuming a five-year lifespan. Many still remain in use, however. An assessment of the historical value of the structures in 1985 noted:2

The bag-manufacturing-and-loading plant was originally planned to be located in the Horseshoe Bend Area next to the manufacturing of powder. After an explosion at a powder plant in New Jersey, redesign of the powder production required more distance between buildings.

In late 1940 the War Department purchased 45 tracts 12 miles away near the town of Dublin, acquiring 4,000 acres for the New River Ordnance Works. It manufactured the bags to hold the powder, and loaded them into projectiles:3

the Radford Arsenal included a New River Unit near Dublin in Pulaski County

Source: Radford Army Ammunition Plant, First Five-Year Review Report for Radford Army Ammunition Plant (Figure 1)

The two facilities were combined in 1945 and renamed Radford Arsenal. The facility was inactivated, except for some manufacturing of ammonium nitrate fertilizer between 1946-1949.

The Radford Arsenal was restarted for the Korean War to supply "smokeless powder" based on nitrocellulose plus rocket propellant. It has stayed in operation ever since then, though a substantial portion of the New River Unit has been sold. The remaining portion currently totals 2,840 acres. The Radford Arsenal was given its current name of Radford Army Ammunition Plant in 1963.4

2,840 acres of the former 4,000 acres in the New River Unit remain part of the Radford Army Ammunition Plant

Source: US Geological Survey (USGS), Dublin 1:24,000 topographic quadrangle

(2022)

Operations are hazardous. By the 75th anniversary of the plant in 2016, there had been 39 deaths since construction began and the first person was killed by a locomotive in December, 1940.

Major accidents included explosion of "A" line of the TNT plant in 1974, and of the Nitroglycerin Plant 2 in 1978. A 1985 explosion of a 5,000-pound batch of nitroglycerine killed two men. The Washington Post reported then:5

The materials used at the facility are highly flammable as well as explosive, and fire is a constant hazard. In 2018, a flash fire in a nitrocellulose drying facility killed one worker and injured two others.6

Hercules was the contractor from construction in 1940-41 through 1995, when it was purchased by Alliant Techsystems (ATK). That company ran the facility until 2012, when it was replaced by BAE Systems as the contractor. ATK protested the award of the 10-year contract with three 5-year options, but the protest was not upheld. The United Steel Workers union has represented the workers since 1952.

BAE began a $240 million facility upgrade after it assumed control of the plant. In 2022 BAE systems was awarded another 5-year contract, with a value of up to $1.3 billion.

the Radford Army Ammunition Plant has been producing the material that provides energy in energetic weapons since 1941

Source: US Army, Radford AP Video

Today, the Radford Army Ammunition Plant is the only manufacturer and supplier of military-grade nitrocellulose in North American. It produces 29 types of propellants, which are shipped to other locations for incorporation in military and civilian ammunition (including pyrotechnics).7

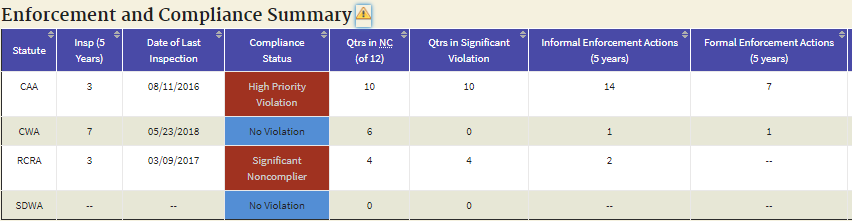

The facility is an environmental challenge. The coal-fired power plants regularly exceeded emission levels authorized by its state air quality permit, until a gas-fired power plant went into operation in 2017. For exceeding air quality permit thresholds for filterable particulate matter, hydrochloric acid, carbon monoxide, and opacity before the coal-fired boilers were shut down, the Virginia Department of Environmental Quality ordered the U.S. Army and contractor BAE Systems to pay a $263,335 fine.8

Annual reports of toxic releases reveal that the Radford Army Ammunition Plant remains Virginia's largest polluter, with large amount of nitrogen waste discharged in wastewater released to the New River.

pollution reaches the New River through groundwater, as well as from surface flow and air deposition

Source: US Army Corps of Engineers, Remedial Investigation Report New River Unit (RAAP-044) (Figure 3-1)

The greatest cause of pollution was the open-air burning of waste materials from the production process. Disposal of material used to manufacture explosives is not routine, and most industrial wastes at the arsenal are not suitable for shipping to the municipal solid waste landfill.

Items were collected in an open field and then burned, after calculating expected dispersal based on weather conditions and the amount of material to be incinerated. Inevitably, the burning sends heavy metals (lead, mercury, chromium) into the air near Bellview Elementary School.

Federal regulations forced factories and local governments to end open burning and build incinerators. Military facilities were granted a "temporary" reprieve under Subpart X of the Resource Conservation and Recovery Act. That solution was adopted for the Radford Army Ammunition Plant, and a closed-air incinerator intended to burn 95% of the waste was funded by the Department of Defense.

Actual sampling of emissions, rather than exclusive reliance upon models, started in 2016. They revealed emissions were higher than projected in the modelling. The 2005 air quality permit issued by the Virginia Department of Environmental Quality (DEQ) expired in 2015.9

After receiving funding in 2019, construction of the complex facility able to burn propellants was planned between 2020-2023. In the interim, the plant modified its open burning process to reduce lead emissions in particular. Results from an air monitor installed in 2017 allowed the Virginia Department of Environmental Quality (DEQ) to report that:10

A new air quality permit was issued in 2021. The permit reduced the amount of propellants and other waste munitions material that could be destroyed by "dry burns" from 8,000 pounds per day to 5,600 pounds per day, and limited burning to no more than 183 days a year. The total of propellants which could be burned was cut by 51%, down to slightly more than 1 million pounds per year.

The previous cap of 2,000 pounds a day for "wet burns," which required accelerants such as diesel fuel to catch fire, was not modified in the 2021 permit.

The facility had already reduced open burning below the new thresholds, in advance of starting to build an incinerator in 2022 that would process 95% of the waste. Local activists still objected to the state agency issuing the air quality permit, claiming that the release of constituents of concern such as carbon tetrachloride, chloroform, and methylene chloride would continue to "poison" the community.

Construction of the incinerator was slow, and completion was delayed until 2026. The facility had to be designed to handle "energetic" material that would burn at a high temperature or even explode, unlike a standard incinerator. The Virginia Department of Environmental Quality (DEQ) permit for open burning did not expire until 2031.11

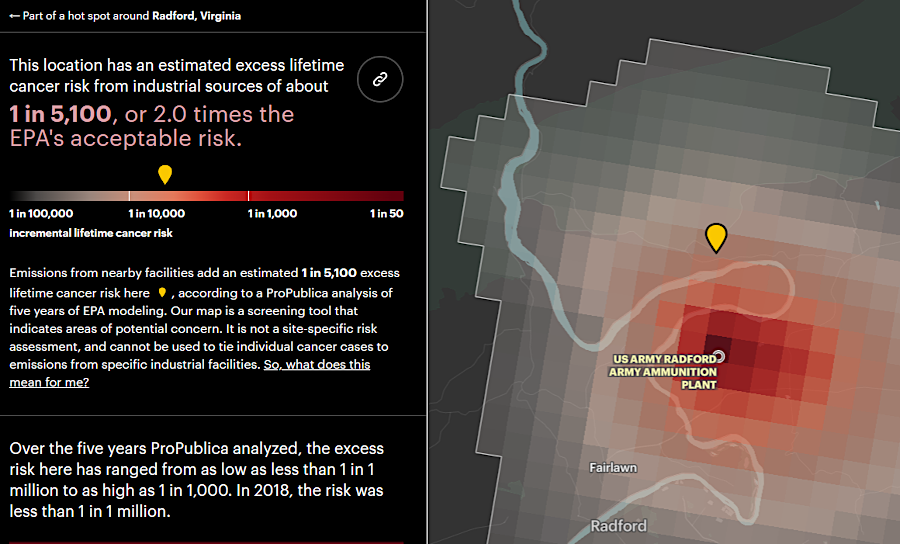

pollution reaches the New River through groundwater, as well as from surface flow and air deposition

Source: ProPublica, The Most Detailed Map of Cancer-Causing Industrial Air Pollution in the U.S.

A ProPublica analysis of Environmental Protection Agency (EPA) data in 2021 assessed the increased risk of cancer for residents living near the Radford Army Ammunition Plant, one of 1,000 toxic hot spots identified across the country. The highest risk was within the grounds of the facility, where there were no long-term residents. However, outside the boundaries the report claimed that the risk was elevated.

As described by ProPublica, 100% of the excess cancer risk for residents on the north bank of the New River was due to the ammunition plant's release of chemicals such as polycyclic aromatic compounds, nitroglycerin and 2,4-Dinitrotoluene:12

The ground-breaking ceremony for the new incinerator, to eliminate 99% of the remaining open-air burning, was held on August 3, 2023. The $145 million facility was scheduled to start operations in 2026.13

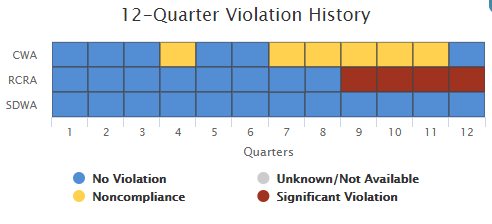

the Radford Army Ammunition Plant has regularly violated Resource Conservation and Recovery Act (RCRA) and Clean Air Act (CAA) standards (graphics from June, 2018)

Source: Environmental Protection Agency (EPA), Enforcement and Compliance History Online, US Army Radford Army Ammunition Plant

Much of the Radford Arsenal's New River Ordinance Unit in Pulaski County, site of a bag manufacturing and loading plant during World War II, was sold to Burlington Industries in 1947. The company processed fabric for textiles there. The Town of Dublin acquired 101 acres and established the Dublin Industrial Park in 1993. Burlington Industries donated an additional 170 acres for the industrial park in 1993. However:14

Dublin received a $1 million Federal grant in 2024 to clean up the brownfield site, and enable it to be used for more industrial and commercial purposes.15

the airspace over the Radford Arsenal is closed to drone flights for national security reasons

Source: Federal Aviation Administration (FAA), Visualize it: See FAA UAS Data on a Map

In September 2024, remnants of Hurricane Helene drenched western North Carolina and caused the second highest documented flood of the New River. Based on weather reports the Radford Arsenal had moved much material out of the floodplain, but like many others in the New River Valley was surprised by the level of the water. The water flooded a warehouse and washed away 13 rigid plastic totes framed with steel filled with 275 gallons of dibutyl phthalate, which is used as a liquid plasticizer to make rocket fuel. Also carried downstream was diesel fuel from flooded tractors and emergency generators, and wastewater that had not been treated yet to remove high levels of calcium sulfate.

The arsenal hired a local canoe/kayak outfitter to search for the plastic totes for 70 miles downstream to the Bluestone Dam in West Virginia. By January 2025, six of the containers with dibutyl phthalate were still missing; two more were found by the end of February. The remaining four containers were likely trapped in debris along the shoreline or underwater. Based on the condition of the first seven recovered containers, some of which had been punctured, nearly 45% (1,575 gallons gallons of the 3,575 gallons) of the dibutyl phthalate was released during the flood. One container was apparently drained on purpose by a local resident who found it, and was presumably unaware of the recovery protocol.

A year after the flood, three containers were still missing.

The failure to keep pollution out of the New River complicated the public reaction to the arsenal's request to switch out the source of nitric and sulfuric acid used to manufacture explosives. The proposal was to recycle acid waste rather than purchase new acid material, and the change required a variance in the wastewater discharge permit issued by the Virginia Department of Environmental Quality (DEQ). Public responses included concerns that the material provided by the arsenal for public review was incomplete and inadequate.

A lawyer working with Citizens for Arsenal Accountability said:16

construction of the Radford Army Ammunition Plant was rapid

Source: US Army, Radford Army Ammunition Plant